Whereas most 3D printing involves plastics or metals, a growing area is in ceramic 3D printing, especially 3D printing clay. Ceramic 3D printers can create intricate and precise clay 3D models, including vases, bowls, plates and even medical instruments.

Now a fast-growing sector, ceramic 3D printing is predicted to become a $3.6bn industry by 2028, across 3D printed jewelry production, vases, 3D printed medical instruments, and even in aerospace.

So, we’ve rounded up the best ceramic and clay 3D printers, as well as included extra sections on the main applications, and how each type of ceramic 3D printing technology works.

The Best Ceramic 3D Printers

1. WASP Delta 2040 Clay 3D Printer

- Price: Check price at Amazon here

- Build volume: 200 x 200 x 400 mm

- Company based: Italy

Pros

Fast and reliable.

Compatible with all major 3D slicers.

The clay and LDM extruders make for accurate and fast ceramic printing.

Cons

Post-processing of parts is difficult due to the enclosed print chamber.

Italian 3D printer manufacturer WASP make some of the fastest 3D printers in the world, and are known for high quality delta 3D printers, as well as for their entries into clay 3D printing. The Delta 2040 can print at speeds in excess of 300 mm/s, using WASP’s clay and LDM (Liquid Deposition Modeling) extruders for accurate and fast ceramic printing.

As well as their standard clays, the clay printer is versatile enough to print any soft paste material that can be extruded under 4-6 bar pressure. The printer uses a 1mm nozzle for precise clay 3D printing.

To get you started, the WASP 2040 comes with a small amount of white porcelain material that you can print with. The printer is compatible with all major 3D slicers, including Cura, Slic3r, and Simplify3D. WASP have a strong reputation for making workhorse 3D printers that print at phenomenal speeds, with the Delta 2040 no different.

2. Cerambot Air

- Price: $599

- Build volume: 170 x 170 x 285 mm

- Company based: China

Pros

Affordable.

Precise layer resolutions and is compatible with nozzle diameters between 0.6-2.2mm.

Cons

Need to assemble it yourself(Unless bought pre-built for an extra $200).

Cerambot made waves when their Kickstarter campaign raised $286,510 to bring their ceramic 3D printers to market. Now after the campaign you can buy the Cerambot Air for $599, or the Cerambot Pro for $699.

The Cerambot Air offers precise layer resolutions of between 0.5-2mm, and is compatible with nozzle diameters between 0.6-2.2mm. However, as a DIY 3D printer you will need to assemble it yourself, though Cerambot offer to assemble it for you for an extra $200.

It prints at speeds between 5-50mm/s, and is compatible with slicers including Cura and Slic3r for accessible ceramic 3D printing.

Perhaps most interestingly, Cerambot also offer a Pro Extruder Kit, which can be adapted to turn your standard FDM 3D printer into a clay 3D printer. The kit costs $299, and you’ll also need to download and print their extruder holding module from Thingiverse, but Cerambot claim it can turn Prusa i3 and Ultimaker 3D printers into ceramic printers.

Overall, at $599, the Cerambot Air is a very interesting ceramic 3D printer option, costing far less than other entry-level rivals.

For industrial 3D printing, Cerambot also sell their construction 3D printer, the Cerambot Tong, for $19,800. This gigantic 3D printer is more focused on architectural and 3D printed house construction rather than standard ceramics.

3. 3D Potterbot Micro 9

- Price: $2,850

- Build volume: 254 x 254 x 305 mm

- Company based: USA

Pros

Durable and corrosion-resistant.

Uses its direct extruder to directly print real clay.

All 3D Potterbot materials are food-grade.

Cons

The open design can lead to temperature issues.

The 9th iteration of the famed Micro clay 3D printer range, the Micro 9 is one of a huge range 3D Potterbot offer, from this entry-level clay printer all the way up to industrial construction printers.

The Micro 9 features a 1000ml extruder, with anodized, durable and corrosion-resistant parts, and a print speed of between 35-60mm/s. Despite the large print volume, even with the extruder attached the Micro 9 only weighs 30lbs.

Whereas most clay 3D printer brands use compressed air systems to print clay mixed with water and other materials, the Micro 9 uses its direct extruder to directly print real clay. All 3D Potterbot materials are also food grade, allowing for many other uses. It also prints via WiFi, which many will prefer over USB or SD card printing.

4. ZMorph Fab with thick paste extruder

- Price: $3,999 – Available on Matterhackers here

- Build volume: 250 x 235 x 165 mm

- Company based: Poland

Pros

Extraordinarily versatile 3D printer.

Can print not only clay but materials like silicone, as well as turn it into a food 3D printer.

Doubles up as an FDM printer.

Cons

Instructions and documents included can be difficult to understand.

An extraordinarily versatile 3D printer, if you purchase ZMorph’s thick paste extruder attachment (which comes with the full set package) you can print not only clay, but also materials like silicone, as well as turn your machine into a food 3D printer and print chocolate, cream cheese and more!

Even if you aren’t always 3D printing clay, the ZMorph Fab doubles up as a great desktop FDM 3D printer, and with it’s 3 in 1 3D printer capability you can quickly also switch it into a CNC mill, or even a laser engraver.

- We also have a ranking of the best all in 1 3D printers

- We also have a ranking of the best food 3D printers

For standard 3D printing, the Fab can print a huge range of materials, from PLA, ABS and PETG to Nylon, PVA, TPU and more with its powerful heated bed which can reach 115C. It also features up to 50-micron accuracy for precise 3D printing with plastics or clay. It’s a great option for those who want to experiment with clay 3D printing but who want to retain standard 3D printing capabilities.

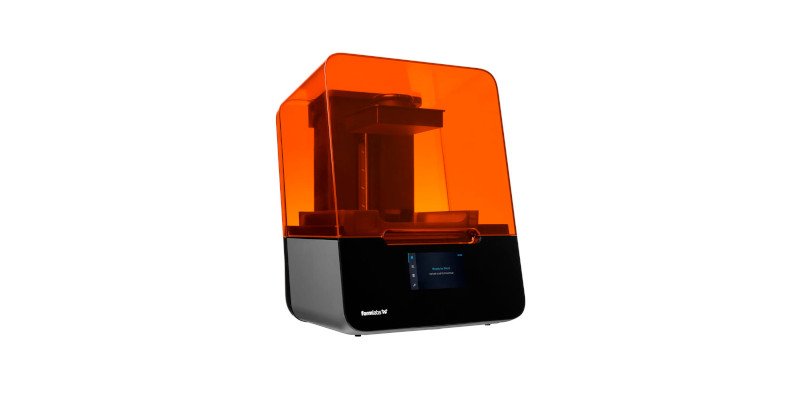

5. Formlabs Form 3 with Ceramic Resin

- Price: $3,499 – Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

- Company based: USA

Pros

Durable and precise.

Makes for precise ceramic 3D printing.

Cons

Not good for industrial-level ceramic production.

The Formlabs Form 3 builds on the Form 2’s success, with key durability and precision improvements that make it further stand out in SLA 3D printing. Originally released in 2018, Formlab’s Ceramic Resin allows you to 3D print fully ceramic parts that can be fired and turned into finished ceramics.

Originally brought out for the Form 2, these cartridges should be fully compatible with the Form 3, with the Ceramic Resin compatible with 50- and 100-micron print resolutions.

SLA 3D printers can print more intricate and accurate parts than delta FDM 3D prints will ever be capable of, so for experimental, precise ceramic 3D printing, this is a great option. However, Formlabs do state that this is an experimental resin, and that it has a lower print success rate than other Formlabs products, so consider this good for experimenting, but less suited to industrial-level ceramic production.

How Ceramic 3D Printing Works

Ceramic 3D printers print “green” parts, unfinished clay parts that require post-print treatment, usually by firing them in a kiln.

Creating ceramic or porcelain 3D prints is the same as with standard plastic 3D printing, requiring a 3D model like an STL file or G-code. Ceramic 3D printers then print the part – the green object – with most clay 3D printing done through either FDM, Binder Jetting, Selective Laser Sintering or SLA 3D printers. Once printed, the part usually needs to be glazed and then fired in a kiln to give the part its finished properties.

You can 3D print ceramics using a variety of different 3D printing technologies, including:

FDM Clay 3D printing

Some specially-designed clay 3D printers – mostly delta 3D printers – can print ceramic materials with adapted extruders for these tougher materials. They extrude paste-like ceramics.

For example, Italian 3D printer manufacturer WASP’s clay 3D printer range, such as their Delta 2040, use air-compressed cylinders to extrude melted clay material using their Liquid Deposition Modeling (LDM) technology. As well as ceramic paste, the same technologies can print porcelain, aluminium, zirconium, and advanced ceramics.

Chinese manufacturer Cerambot have also released a number of low cost clay 3D printers. In addition to selling the printers, they have also developed custom ceramic extruders which can turn your standard desktop 3D printer into a ceramic printer. They claim this works well on printers such as the Prusa i3, and Ultimaker printers.

Binder Jetting Ceramic 3D printing

3D printer manufacturers such as Voxeljet offer Binder Jetting 3D printers to print accurate and large ceramics. Binder Jetting is favored for its ability to print ceramic parts with precise details, as well as not having any of the shrinkage during sintering associated with other forms of ceramic 3D printing.

Resin ceramic 3D printing: SLA / DLP

Resin 3D printers are not thought of as ceramic 3D printers, but Formlabs recently introduced a ceramic resin for use with their Form 3D printers. However, the resin is still considered experimental. 3DCeram also use DLP 3D printing methods within their industrial ceramic 3D printers.

Ceramic 3D Printing Applications

Currently, ceramic 3D prints are used in niche areas of automotive and aerospace production due to these parts’ light weight, strength, and temperature resistance in hot areas. Ceramic parts also have uses in aviation for their durability, such as in fuel nozzles.

In the future, it is thought that ceramic 3D printing applications will include medical implants, which can be made quickly and accurately on future ceramic SLA or DLP printers. Binder jetting is thought to be a good candidate for ceramic 3D printed prosthetics of the future.

Artists have also taken advantage of ceramic 3D printing and its boundless options to design some of the most beautiful 3D printed vases and other ceramics.

These include Oliver van Herpt, who has been involved in clay 3D printing since before it was easily accessible. Seeking a way to accurately create intricate ceramics, he found there were not any clay 3D printer extruders available at the time, and set out to create his own. Having designed his own custom clay 3D printer, he now creates some of the most precise and intricately detailed ceramics and has exhibits all across Europe.

How Much Do Ceramic 3D Printers Cost?

Most ceramic 3D printers cost upwards of $10,000, and are reserved only for industrial applications and the construction industries. However, there are a few cheaper emerging clay 3D printers, some of which are very highly rated by hobbyists and makers worldwide.