PVA filament is the most popular water-soluble filament out there, and my favorite way of adding easy-to-remove supports when producing models with intricate detailing or overhanging features.

This blog will step you through everything you need to know about 3D printing with PVA – including my personal recommendations for filaments, equipment and settings for best results.

This non-toxic material is used not only within the realm of 3D printing filament but also in almost every facet of modern life – and an excellent choice for 3D printers looking to produce sturdy supports without the hassle of chemicals or power tools in removal.

- We also have an in-depth guide to all major 3D printer filaments.

- PVA 3D Printing Properties

- PVA 3D Print Speed & Temperature

- Advantages and Disadvantages of 3D printing PVA

- Which PVA Filaments are Best?

- Best PVA 3D Printers

- What Can You Use PVA Filament For?

- How to Store PVA Filament

- Water Soluble Filaments: PVA vs HIPS

- Making PVA Filament

- Is PVA Good for the Environment?

- History of PVA in 3D Printing

PVA 3D Printing Properties

In 3D printing, PVA’s water solubility makes it an excellent support to models that include intricate detailing or involve overhanging features. Not only is it water-soluble, it’s also odorless, colorless, soft, biodegradable, and non-toxic at low concentrations.

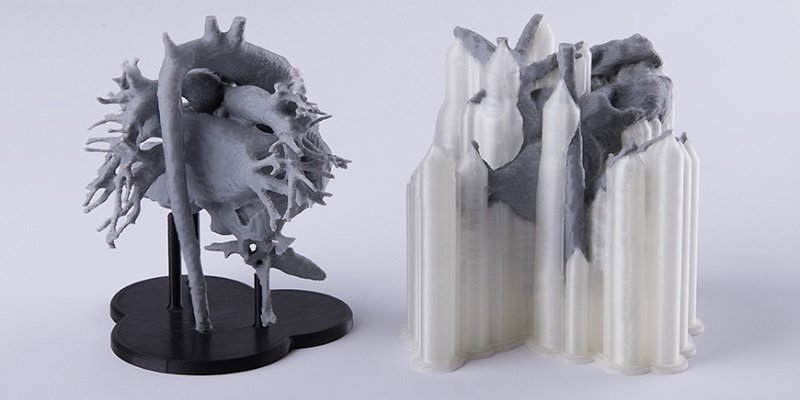

As you know, a 3D printer starts printing an object from the bottom up. This means that if your design incorporates overhangs over 45 degrees, or bridged areas that don’t have any underlying material, you’re going to run into problems. After all, your printer filament is subject to the law of gravity. It can’t be extruded onto thin air.

If your filament is low temperature and cools fast, you can often make small bridges and overhangs without support and you’ll get a nice clear bridge. But anything larger and you’re likely going to need supports.

PVA solves this problem by providing the support medium for these overhangs. Your printer first lays down a layer of PVA support material underneath the area where the overhang will be.

Once the PVA 3D printing filament is in place, your printer is able to continue laying down the upper levels of your model. By using PVA 3D printer filament, you avoid the warping or total collapse that would occur if the PVA wasn’t there.

Within 3D printing, PVA is most known for being a support material for dual extruder 3D printers. Most typically it is used in combination with PLA, not only because of PLA’s popularity, but also because both have very similar extruding temperatures.

- We also have a ranking of the best dual extruder 3D printers.

Why Use Water Soluble Support Filament?

Well, getting rid of the PVA support material once you’re done printing couldn’t be easier. There’s no mess and no need to use expensive chemicals, knives or power tools in order to remove what you don’t want.

All you do is simply submerge your model in water for a couple of hours (up to 24 for bigger prints). The PVA dissolves away completely, leaving you with sharp, clean lines on the overhanging areas of the object that you’ve created.

Warm water can speed up the process. Some more complicated prints may take longer.

Using a soluble support material like PVA requires that you use a printer with dual (or more) extruders. One extruder handles the support material, the other handles the main printing filament.

If you’re not currently using a dual extruder printer, it’s very likely that you can easily upgrade in order to get the increased flexibility and creativity that multiple extruder printing offers.

For example, two extruders not only allow you to use support materials, they also allow you to print in more than one color.

Now that you know what PVA is and how it is used, let’s take a look at some of its features:

- It is water-soluble, biodegradable, and non-toxic

- It has high tensile strength and is also quite flexible

- It is odorless when used in printing

- It easily adheres to other substances

- It resists oil, grease, and solvents

- PVA will begin to partially hydrolyze (breakdown) at a temperature of 180°C

- Therefore, PVA filament temperature for printing is between 190°C and 210°C

- PVA tends to work better with PLA than ABS, since the higher printing temperatures that ABS requires sometimes means that PVA will have trouble adhering.

PVA isn’t the only soluble support filament available for use in 3D printing. There are other soluble support filaments, such as HIPS, that essentially do the same thing as PVA.

PVA 3D Print Speed & Temperature

Like all 3D printing materials, knowing the specific PVA filament properties will make your print as successful as possible.

First, you want to keep your fan speed a bit on the low side since PVA can be fragile while extruding.

Next, set the temperature of your bed to between 50°C and 60°C, maybe a tad hotter for the first few passes. This will help with adhesion. We also recommend a printing temperature of between 190°C and 210°C, depending on your extruder.

Regarding the best PVA filament settings; you want to keep your printing speed slower than normal, somewhere around 30mm/sec. If you go faster than that you run the risk of the material not lying properly.

The balancing point with finding the best PVA filament temperature (or the sweet spot where it prints nicely) is that you don’t print any hotter than you absolutely need to. Depending on what you’re printing (if there aren’t many overhangs or bridges) if the support material extruder is left hot for a while in between printing, it can clog up the extruder.

A lot of the problems that people experience when printing with PVA comes from using a low-quality filament. PVA that contains impurities and additives can cause inconsistent melting which, in turn, can cause blobbing, irregular flow and clogged extruders.

When you use a high-quality PVA you avoid all of the above problems. You save time, you save money and you eliminate the frustration of watching a carefully planned print go down the drain.

With the exception of part-cooling fans, which are required, PVA does not need any additional equipment for 3D printing, however, some optional hardware may make life a little easier.

Other PVA filament best practices and tips and tricks include:

- PEI sheets or painters tape build surface are recommended.

- An ooze shield is optional, but recommended.

- Adjust your 3D slicer infill settings to make your filament go further. Use a low infill percentage throughout your PVA support structure, and then using a higher percentage only where it contacts the print.

Advantages and Disadvantages of 3D printing PVA

Benefits of PVA Filament

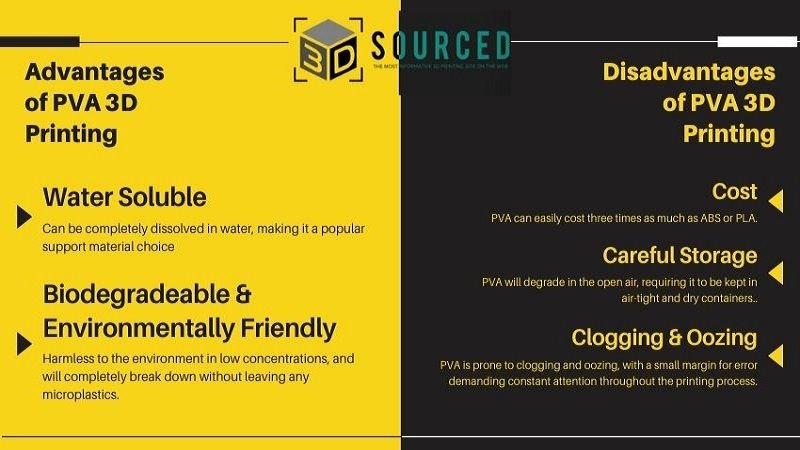

Water soluble: Being entirely water soluble allows PVA to be used as a dissolvable support material. Dissolving PVA leaves no blemishes on the final print, as no force is used to remove the supports.

Biodegradable & environmentally friendly: PVA will completely biodegrade, and is harmless to the environment in low concentrations.

Drawbacks of PVA Filament

PVA filament doesn’t require any special steps to get the best results. However, PVA can have a smaller margin for error than more typical filaments. With that in mind, here are some common pitfalls to avoid:

Requires careful storage: Being entirely water-soluble means that the filament can have strong reactions to any form of moisture, even in the air. If not stored correctly, or if the filament contacts moisture before printing, then the final prints can bubble or crack, degrading their final quality and strength.

Expensive: PVA is expensive, easily costing two or three times as much as ABS or PLA filament.

Clogging and Oozing: Although not considered an especially challenging material to work with, PVA does have a smaller margin for error when compared to PLA. If the printhead temperature is set too high, or even if the printhead is left idling for too long, then PVA will either ooze or degrade and essentially cook inside the nozzle, clogging it. Even with your temperature set up correctly, PVA is still prone to oozing, especially between prints. To avoid this, we recommend using an ooze shield, and being vigilant with cooling down your printer nozzle between prints. We also recommend removing any unused PVA from your printer when not in use to limit its exposure to potentially humid air.

Which PVA Filaments are Best?

We recommend the following PVA filaments:

- Matterhackers MH range of PVA 3D printing filaments

- Dynamism range of PVA filaments

- Selection of PVA we recommend on Amazon

Best PVA 3D Printers

As it is rarely used on its own, only dual extruder printers can effectively 3D print PVA. These printers have two print heads, and can be loaded up with two different materials, such as PLA and PVA.

So, if you’re looking for a PVA 3D printer, view our dual extruder 3D printer ranking here.

What Can You Use PVA Filament For?

PVA filament’s main application is that of a water-soluble support material for dual extruder printers. Being both non-toxic, soft, and easily dissolved in water, it is ideal as a support filament, able to be easily removed without blemishing the final print.

PVA can also support complex shapes, or fill concave or hollow objects, allowing these opbjects to be easily printed and supported where breakaway supports would struggle.

Outside of 3D printing, PVA’s non-toxic properties allow it to be used in many of the plastic household objects we take for granted. Laundry capsules such as Tide pods, disposable contact lenses, coatings for pills and tablets, fishing bait-bags, food packaging and biodegradable plastic bags are all common uses for PVA.

How to Store PVA Filament

It is important to store your PVA correctly to ensure that it comes into as little contact with moisure as possible before printing. Dry PVA will give you the best printing results, and will be far less likely to ooze or clog in your printhead.

Ensure that it is always stored in an air-tight container: Most PVA will be delivered in a sealed or air-tight disposable bag, a bag that will predictably become a lot less airtight once opened. Ensure that before you open these bags, that you have an air-tight container ready to store your filament.

We recommend the following filament storage:

Recovering Wet PVA

If your PVA does become wet the spool isn’t necessarily ruined, as there are ways to recover it.

Assuming that your spool hasn’t completely dissolved like cotton candy, your first clue as to whether your PVA has absorbed too much water will be a soft and sticky texture, or the filament appearing warped. Your next clue will be a hissing or steaming printhead while in operation, and your final clue will unfortunately be a poor-quality print.

Recovering your PVA is luckily as simple as using a commercially available dehydrator. Failing that, your PVA can be dehydrated by heating it. We recommend heating it to between 45⁰C-55⁰C for two hours on a heated build-plate, or 113⁰F-131⁰F in an oven. Exact drying times and temperatures will vary depending on your brand, and how wet your filament is, so expect a measure of trial and error when trying to dehydrate your PVA.

Alternatively, you can purchase a filament dryer. These are specially designed to dry your filament and replenish its best 3D printing properties. We recommend the following:

Water Soluble Filaments: PVA vs HIPS

PVA is not only water-soluble, it is also hygroscopic. This means that it naturally absorbs water from the air that surrounds it. This makes PVA extremely sensitive to humidity.

If PVA is exposed to air that contains too much water it will begin to lose its tensile strength and degrade. Therefore, it is always important to store PVA in an airtight container, perhaps one containing a desiccant, especially if you live in a climate that experiences high humidity on a regular basis.

HIPS does not have this problem, since it is neither water-soluble nor hygroscopic. However, HIPS’ non-water solubility gives rise to another problem – removing it as a support medium once you’re finished printing.

Unlike PVA, you can’t simply chuck a HIPS model in water. Instead, in order to remove HIPS you have to use Limonene, a chemical solvent. Unlike water, Limonene isn’t odorless. So, using HIPS can be, potentially, more irritating than using PVA.

In the end, it comes down to a matter of preference. PVA requires more careful storage than HIPS, but is water-soluble. HIPS is easily stored, but requires a chemical solvent to remove. If you don’t mind taking the steps to protect PVA in storage then it probably provides an easier soluble support solution than HIPS.

Making PVA Filament

Polyvinyl Alcohol begins life as Polyvinyl Acetate (white glue). It is first dissolved in alcohol, usually methanol or ethanol, before being treated with an alkaline catalyst such as sodium hydroxide in a process fittingly called “Alcoholysis,” a specific type of hydrolysis reaction. Once completed, the “acetate” groups are removed from the molecule, resulting in Polyvinyl Alcohol.

Raw PVA usually comes in the form of solid pellets or a solution. Once thoroughly dried out, it can be extruded and rolled into a spool, ready for 3D printing.

Is PVA Good for the Environment?

PVA will completely biodegrade, with PVA and starch blends theorized to take just over 12 years to degrade by 70%. By comparison, PLA would take 80 years to completely degrade if left in an open environment.

Its low toxicity also means that water solutions can be safely disposed of down the sink, with the solution easily filtered out by treatment plants. Even untreated water concentrations of less than 5% are safe for fish.

Additionally, unlike other plastics, PVA has no risk of producing micro-plastics. As it biodegrades it breaks down into monomers, which in turn decompose into nutrients and safely re-enters the environment.

The result is a zero-waste product which, if properly managed, has no long-term environmental impact. A truly guilt-free 3D printing filament.

History of PVA in 3D Printing

PVA was first discovered in 1924 by German Nobel Laureate Dr Hermann Staudinger. Japan began PVA research, resulting in “Synthetic Fiber No. 1” being produced in 1939, under Professor Ichiro Sakurada of Kyoto Imperial University. The research was then picked up by the Kuralon company, becoming the first company in the world to mass-produce and commercialize PVA fibers in 1950.

Although PVA filament could have been produced from the inception of 3D printing, it struggled to find a use until the adoption of multi-material 3D printing in 2006. Rather than just being able to print an object that will ultimately degrade in the open air, suddenly, the opportunity arose for PVA to be used in its now defining role, as a water-soluble support material.