The right extruder is essential to high-quality, smooth and successful 3D printing. Low-quality extruders restrict which filaments you can print, struggle to melt at high flow rates, and struggle with filaments like flexibles.

So, we’ve rounded up the best 3D printer extruders, as well as explained their intricacies, the different types of the extruders, and their advantages and disadvantages.

Quick Overview

| Name | Estimated Price | Best place to buy (with link) |

|---|---|---|

| E3D V6 | $61 | Amazon here |

| Diabase Flexion Single Extruder | $149 | Amazon here |

| Diabase Flexion Dual Extruder | $249 | Amazon here |

| E3D Titan | $59 | Amazon here |

- We also have a dedicated article for 3D printer hot ends.

- We also have a dedicated article for 3D printer nozzles.

- For information on all parts, we have an in-depth guide to every part of a 3D printer.

Best 3D Printer Extruders & Hot Ends

1. E3D V6

E3D make some of the best hot ends around, it’s undeniable. They even sell the V6 as “the one all the other hot ends want to be”.

One of the reasons for its such strong performance is the clever way the PTFE tube takes filament away from any heat when extruding, which is especially useful when printing flexible and softer filaments that are more at risk of deforming when near heat. As a result, the E3D V6 can print flexible and soft filaments as well as tough, strong ones.

It’s built to avoid filament clogging and maintain consistent filament flows and extrusion, and it’s the hot end of choice for Lulzbot and Prusa printers, a fairly enormous co-sign. We highly recommend the E3D V6.

2. Diabase Flexion Single / Dual Extruder

- Single extruder price: Check at Amazon here

- Dual extruder price: Check at Amazon here

A brand of extruders designed to handle flexible filaments such as TPU with ease, Diabase extruders are compact and lightweight, yet still effective and powerful without risking overshooting.

Depending on your 3D printer, you can get either the single or dual extruder version to upgrade your printing, and is commonly used on printers by brands such as Makerbot or Wanhao to replace any MK8 or MK10 extruder. These extruders and hot ends don’t come cheap but are effective, especially for those who want to print a lot of flexible filament.

3. E3D Titan Extruder

- Price: Check at Amazon here

Another extruder by E3D, and one compatible with both 1.75mm and 3mm filament, it is designed to work seamlessly with an E3D hot end to upgrade your 3D printing experience.

It’s a lightweight yet powerful extruder, made of robust injection molded parts, and it is also compatible with third party parts if necessary. If you intend to run it as a Bowden extruder you will have to buy a Bowden adaptor, so factor this into your cost.

What is a 3D Printer Extruder?

Though extruder is the name that stuck, a 3D printer extruder is actually more of a ‘feeder’. This is because the 3D printer extruder is responsible for pushing the correct amount of filament to the hot end where it is then melted and extruded.

The extruder is a series of important parts that work together to move the filament to the hot end, which heats filament up to be deposited during the FDM 3D printing process. Extruders are sometimes confused for the hot end, when actually they are considered different parts.

The extruder is not involved in the actual heating process and merely sends the correct of filament to the hot end for 3D printing, thereby earning its nickname of the ‘cold end’.

Cold End

The 3D printer extruder is sometimes referred to as the cold as is the upper portion that feeds the 3D printer filament towards the hot end to be melted and deposited.

The cold end’s position within a 3D printer will vary based on type of extruder it is.

This is separate to the hot end, though because they are closely linked we will explain the hot end also.

Hot End

The hot end is a vital part of any FDM 3D printer, responsible for melting and depositing the filament so it falls exactly where it is supposed to be and build your part. A good quality hot end makes prints less likely to fail, enables you to print with more materials, and improves print quality.

How to convert a 3mm extruder 3D printer to 1.75mm extruder?

3D printer extruders need to be made according the size of the filament being used with the 3D printer. In the past, 3mm filaments dominated the marketplace, and 3D printers were commonly fitted with 3mm extruders to compensate. However, now 1.75mm filaments are more common, extruders are usually built to accommodate 1.75mm filament.

If you have a 3mm extruder you can easily convert it into a 1.75mm extruder with a few simple tools, a PTFE tube, and a 1.75mm hot end.

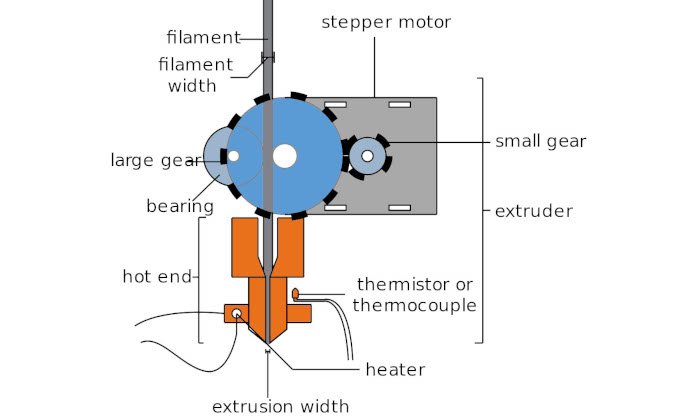

3D Printer Extruder Parts

There aren’t actually too many parts to a 3D printer extruder. These main parts include:

- Stepper motor: usually a NEMA17 stepper motor.

- Filament drive gear: this part guides the filament through the hot end. Either a steel gear with teeth cut into it (called a ‘hobbed gear’) or a hobbed bolt. They are driven by geared extruder motors.

- Idler: the part that holds the filament against the drive gear to extrude it through the hot end. Usually a bearing or a PTFE tube.

The hot end contains the heater cartridge, thermistor, heater block, heater break and the nozzle.

Though involving few pieces, slight changes in these pieces can result in large discrepancies in 3D printing results. For example, the idler’s teeth cannot be too fine or too thick, as each extremity can cause filament clogging during 3D printing. Most idlers are made specifically for this purpose however so you shouldn’t need to worry.

Read more: 3D printer extruder clicking/slipping – every cause and fix explained

3D Printer Extruder Types

There are two main types of 3D printer extruder. These include direct extruders, and bowden extruders. There are also dual extruder 3D printers, printers which use two extruders rather than just one.

Dual Extruder 3D Printer

Dual extruder 3D printers allow for two different print heads to operate simultaneously, opening up a variety of new possibilities.

Firstly, two materials can be printed concurrently in each extruder. This can help for example as you can print supports in a different, soluble material to improve surface finish. Moreover, having a dual extruder means you can print objects in two colors, for those who enjoy colorful builds.

Dual extruders aren’t a different type of extruder however, just the option of having two of them. The main two types explained below are direct extruders and bowden extruders.

- View our buyer’s guide for the best dual extruder 3D printers.

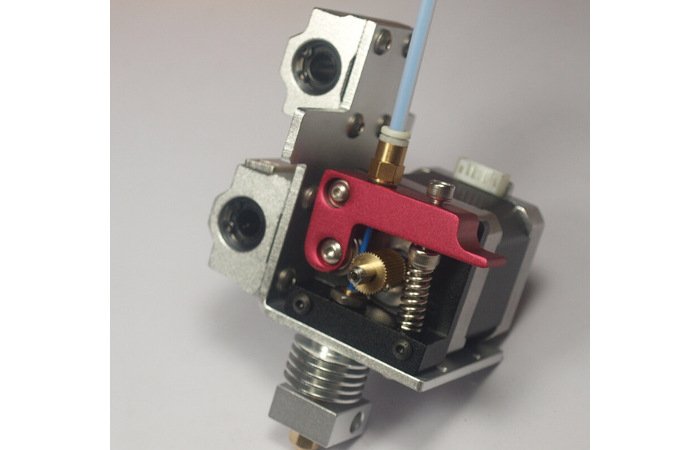

3D Printer Direct Extruder

Direct extruders are called direct because, literally, they are directly attached to the hot end. Used in 3D printers such as the Lulzbot Mini (featured in our best 3D printer ranking), most plug and play 3D printers are direct extruder 3D printers. They often incorporate gears, especially in DIY 3D printer kits.

Direct extruders being attached to the hot end minimizes the distance the filament needs to travel, so there are less variables at play that can go wrong, and less time / distance for the filament to run into problems. This is thought to be especially useful in 3D printing flexible filaments.

The combined hot end and extruder means the combined 3D printer part is heavier.

Direct Extruder Strengths

- Shorter distance to the hot end — so better responsiveness to extrusion. This better responsiveness means cleaner prints and better surface finish overall. Moreover, this results in less force or torque necessary to extrude filaments, so you can use a smaller motor or use less exerting settings.

- Better for printing flexible materials — though not all the time, there are some examples of Bowden extruders that can perform flexible materials without issue, but the general rule is that direct extruders can print more consistently with flexible materials like TPU or Nylon.

Direct Extruder Weaknesses

- Heavier and more mass overall — this larger mass can result in overshooting and cause frame wobbling due to problems decelerating and accelerating, reducing part quality. However, effective slicing and printing settings can largely negate this.

- Generates more heat on motors — also due to the heavier mass causing extra exertion.

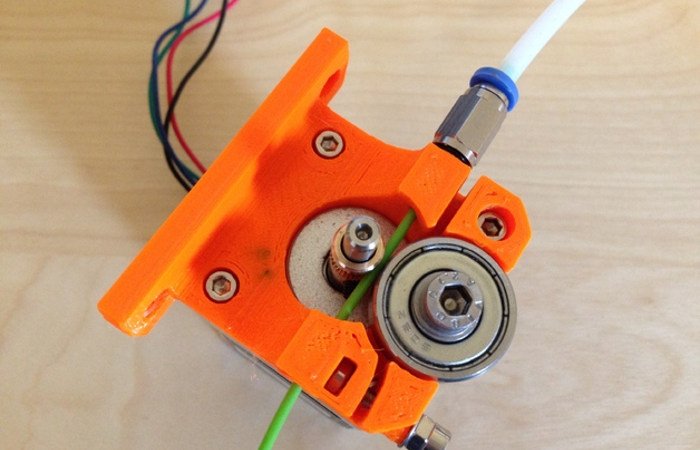

3D Printer Bowden Extruder

Bowden extruders differ from direct extruders as they are not directly attached to the hot end. They instead have a PTFE tube which connects the extruder to the hot end, sometimes called a ‘bowden tube.’ This 3D printer extruder type is used in printers such as the Ultimaker 3, known as one of the best 3D printers in the world.

Instead of being directly attached to the hot end, they are usually mounted on the printer’s frame, and so the hot end is lighter without an extruder on top of it

Bowden Extruder Strengths

- Lighter, and faster 3D printing — separating the extruder from the hot end means reduces weight, as the heavy extruder body can be mounted on the printer body instead of moving around whilst printing. This means 3D printers featuring a bowden extruder can print more quickly, accelerating and decelerating much faster.

- Less overshooting — without the additional weight of the extruder on the hot end, the 3D printer can decelerate and accelerate more effectively, creating parts with cleaner surface finishes.

- Delta 3D printer compatibility — most delta 3D printers can only work effectively with a Bowden extruder.

Bowden Extruder Weaknesses / Limitations

- Print lag — filament has a longer distance to travel between the idler and hot end before being printed, which can result in a slightly less refined print and oozing or stringing of the filament. Since there’s extra lag, this needs to be countered in your 3D slicer settings before printing, which can remove almost all negative effects.

- More friction on the filament — due to this further distance for the filament to travel. This makes 3D printing with flexible filaments such as TPU far more difficult.

- Can be difficult to switch filaments — with a bowden extruder 3D printer less force can be applied to filaments than with a direct extruder, which can make switching filaments more difficult.