We’ve picked out the best FDM 3D printers in every price range, from $200, to $500, to the best under $1000, and even the best professional FDM printers if you’re a commercial business.

|

4.5

|

4.7

|

4.6

|

|

$209

|

$499

|

$439

|

|

220 x 220 x 250 mm

|

220 x 220 x 250 mm

|

420 x 420 x 480 mm

|

|

180 mm/s

|

600 mm/s

|

500mm/s

|

|

260°C

|

300°C

|

300°C

|

|

|

Quick Overview

| Name and Brand | Build volume (mm) | Max Print Speed | Max Nozzle Temp | Price | Best Price At: | Alternative Purchase Option |

|---|---|---|---|---|---|---|

| Anycubic Kobra | 220 x 220 x 250 | 180mm/s | 260°C | $299 | Anycubic here | Amazon here |

| Creality Ender 3 V2 | 220 x 220 x 250 | 80 mm/s | 260°C | $249 | Creality Store here | Amazon here |

| Qidi Tech X-Plus 3 | 280 x 280 x 270 | 600mm/s | 350°C | $749 | Amazon here | |

| Elegoo Neptune 4 Max | 420 x 420 x 480 mm | 500 mm/s | 300°C | $439 | Elegoo here | Amazon here |

| Snapmaker 2.0 | 3 size options | 350 mm/s | 275°C | $1,199-$1,799 | Snapmaker here | |

| Creality K1 | 220 x 220 x 250 mm | 600 mm/s | 300°C | $499 | Creality here | Amazon here |

| Ultimaker S3 | 230 x 190 x 200 | 50 mm/s | 280°C | $3,850 | Dynamism Store here | Matterhackers here |

How We Picked

We don’t claim to be the ultimate authority on 3D printing, just a guiding voice. However, even though this list is subjective, we are knowledgeable and have personally tested over 20 printers.

This is the general criteria we used to evaluate and rank our top FDM printers:

- Build volume – A larger print volume can make all the difference for some projects and hobbies. Small build volumes aren’t the end of the world, but large ones are a plus.

- Reliability – This is a catchall for how much tinkering and troubleshooting you can expect from your printer. Although expected for budget printers, it’s a major con if you’re playing printing issue whack-a-mole every time you start a new project.

- Customizability – On the flip side, customizability is crucial for anyone who is actively seeking out an engineering project. Proprietary tech is a no-no, while open-source printers using generic parts are much easier to customize.

- Leveling features – Since so many hobbyists struggle with leveling, it’s important to know how difficult the leveling process will be. Large build plates make it more difficult, while mesh bed visualizations and various auto-leveling processes can help.

- Quality of Life – Touchscreens, tool trays, filament sensors, and similar features count as quality-of-life features. They probably won’t be the deciding factor, but they matter.

- Special Features – Some printers stand out because they have special features, such as enclosures, different formats (like CoreXY), or better firmware.

The Best FDM 3D Printers 2024 – Reviews

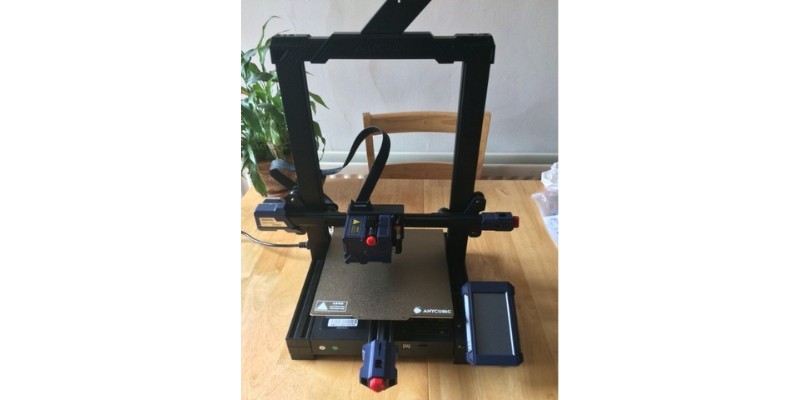

1. Anycubic Kobra – Super budget pick

- Price: Check latest price at Anycubic here / Amazon here

- Build volume: 220 x 220 x 250 mm

- Filament compatibility: PLA, ABS, PETG, TPU

- Layer height: 50-300 microns

- Printing accuracy: ± 0.1 mm

- Max nozzle temp: 260°C

- Max bed temp: 110°C

- Connectivity: USB, Micro SD Card

Pros

Automatic bed leveling

Textured PEI-coated build surface

Direct drive extruder

Cons

Cheap construction in some places

Launched in 2022, the Anycubic Kobra has quickly become the go-to printer for makers on a budget and beginners among enthusiasts and the press.

With efficient automatic bed leveling, a direct drive extruder, and a fantastic PEI-coated build surface, the Kobra has a spec sheet that reads like that of a printer twice its price. It oozes with value, and Anycubic has done well to cut corners where it matters least, chiefly with the plastic material used for the print head casing and spool holder.

Features aside, the Anycubic Kobra has everything you need to produce excellent quality prints for the price. It’s also easy to assemble and set up to boot. Though it excels mainly with PLA, it’s no slouch with flexibles like TPU, thanks to the direct drive extruder.

2. Creality K1 – Super fast enclosed large CoreXY

- Price: Check latest price at Creality here / Amazon here

- Build volume: 220 x 220 x 250 mm

- Filament compatibility: ABS, PLA, PETG, PET, TPU, PA, ABS, ASA, PC, PLA-CF, PA-CF, PET-CF

- Layer height: 100 microns

- Printing accuracy: ± 0.1 mm

- Max nozzle temp: 300°C

- Max bed temp: 100°C

- Connectivity: USB, WiFi

Pros

Fully enclosed

CoreXY design for faster print speeds

LiDAR and built-in camera

Cons

Potentially will need more tinker time

Loud fans

Like many Creality machines, the Creality K1 has set itself apart as a cheap, budget-friendly way to get your hands on new-ish 3D printing tech. The only caveat is that you’ll probably spend more time tinkering than with similar printers like the Bambu P1P.

The K1’s CoreXY design allows for impressive speeds of 600mm/s. By Creality’s measurements, the typical speed is around 300mm/s and the travel speed is 800mm/s. Now, exactly what you’ll be able to attain depends on a variety of different factors, but it’s safe to say that the K1 is high-speed.

Creality has published a real-time print test of a Benchy using the K1 that clocks in at under 12 minutes.

Beyond print speed, the Creality K1 is decked out with a ton of quality assurance tools for (hopefully) reliable prints. It’s fully enclosed, has hands-free auto leveling, dual cooling fans, LiDAR, and a built-in camera. The LiDAR can help you monitor your print while it’s in progress and works in tandem with the K1’s self-testing options.

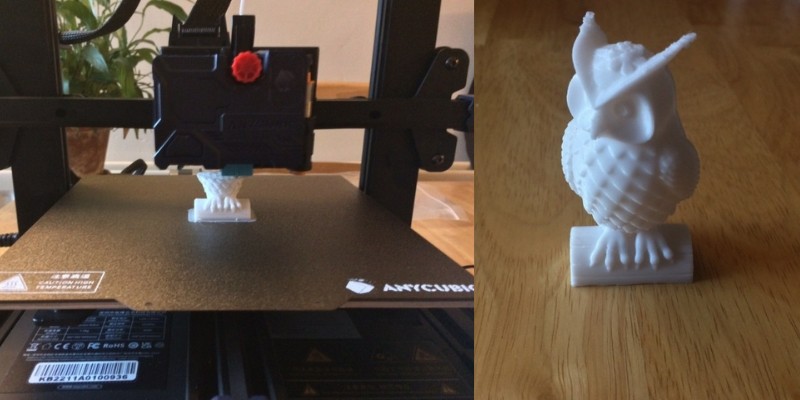

3. Ender 3 V2 – Customizable and Cheap FDM Printer

- Price: Check latest price at Creality here / Amazon here

- Build volume: 220 x 220 x 250 mm

- Filament compatibility: PLA, PETG, TPU

- Layer height: 100 – 400 microns

- Printing accuracy: ± 0.1 mm

- Max nozzle temp: 260°C

- Max bed temp: 100°C

- Connectivity: USB, WiFi

Pros

Huge community backing

Fun 3D printing project with room for customization

Cons

Mediocre features by default

Longer assembly time

Currently one of the world’s most popular 3D printers, the Ender 3 V2 costs under $300 yet has proven itself a reliable and quality option. It’s a 3D printer kit, but it takes less than 45 mins to assemble and even most beginners will find the building process simple enough.

For standard home printing in PLA and ABS or flexible filaments like TPU, it works well. And if you do run into trouble, there are plenty of owners’ groups on Facebook, Reddit, and other platforms to help you out.

Creality has put out a few different variations on the Ender 3 V2 model, most notably the V2 Neo and the V3 KE. We’ve completed a full hands-on test of the Ender V2 Neo, which we found to be a worthwhile upgrade to the V2. It adds auto-leveling and a quicker build time, making it a more modern and accessible option.

The V3 KE will cost you a little more than the default V2, but it comes with bonus features like a filament sensor, more resilient hotend, better cooling, and even uses the superior Klipper firmware.

Overall, the Ender 3 V2 works great for printing the odd useful piece and any standard projects, and can be just about as powerful as you make it.

4. Qidi Tech X-Plus 3 – Best enclosed under $1K

- Price: Check latest price on Amazon here

- Build volume: 280 x 280 x 270 mm

- Minimum layer height: 0.05 mm

- Bed leveling: Automatic

- Max extruder temperature: 350°C

- Max bed temp: 110°C

- Filament compatibility: PLA, ABS, PETG, TPU, PC

- Connectivity: USB, WiFi, Ethernet

Pros

Astoundingly quick due to the Klipper firmware and CoreXY motion system.

Produces top-notch FDM 3D prints. Detailed and precise models every time.

Generous build volume allows for larger and more ambitious printing projects.

Cons

Software and interface have quirks.

Potential learning curve for beginners.

The Qidi Tech X-Plus 3 is my go-to for speedy, high-quality FMD prototyping.

Thanks to the Klipper firmware and CoreXY motion system, it’s astoundingly quick, producing top-notch FDM 3D prints like a 3DBenchy in just 17 minutes!

The spacious build volume, user-friendly direct drive extruder, and auto bed leveling make every print a breeze. And with its spring steel bed and a hotend that heats up to 350°C, I’ve been able to experiment with a variety of materials.

Sure, the software and interface have their quirks, but the X-Plus 3’s ability to produce fantastic FDM prints in a snap more than makes up for it.

Check my full Qidi Tech X-Plus 3 review to learn more.

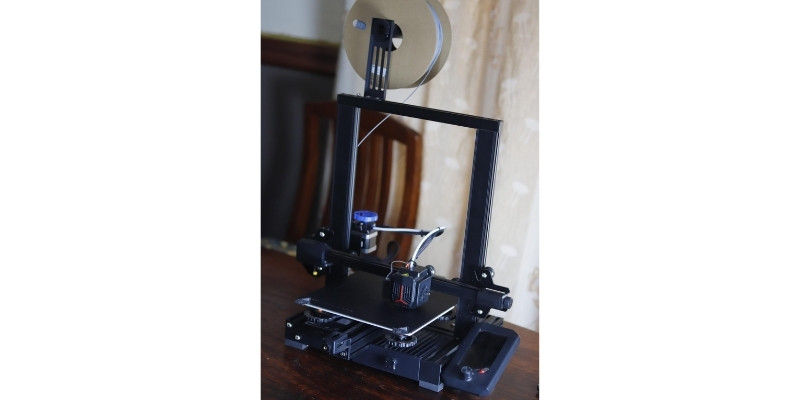

5. Neptune 4 Max – Best budget large FDM printer

- Price: Check latest price at Elegoo here / Amazon here

- Build volume: 420 x 420 x 480 mm

- Filament compatibility: PLA, TPU, PETG, ABS, ASA, Nylon

- Layer height: 100 microns

- Printing accuracy: ± 0.1 mm

- Max nozzle temp: 300°C

- Max bed temp: 85°C

- Connectivity: USB, WiFi, WiLAN

Pros

Large build volume

Pre-installed Klipper

121-point auto leveling

Cons

Expect tinkering and troubleshooting – not for complete beginners

Limited upgrades from Neptune 3 Max

Finding a printer that’s big enough for specialized needs– like cosplay or figurines– usually means paying a lot of money to match the size. The Elegoo Neptune 4 Max tries to be the middle ground between premium prices and premium build volumes.

It has an impressive build volume of 420 x 420 x 480 mm, a solid nozzle temp of 300°C, and the potential for incredible print speeds using Klipper. The only downside of the Neptune 4 Max is that its low price and newness to the market has resulted in some cases of unreliability. You should expect to need to fiddle with it to get good, consistent results.

Although we loved the printer during our hands-on testing session, it was definitely not an “it just works” type of printer.

Thankfully, Elegoo is known for having great customer service. If you have the time and stamina for troubleshooting but can’t afford the build volume on any other printer, the Neptune 4 Max is perfect for you. You might also want to consider the Neptune 3 Max as a similar, less risky alternative.

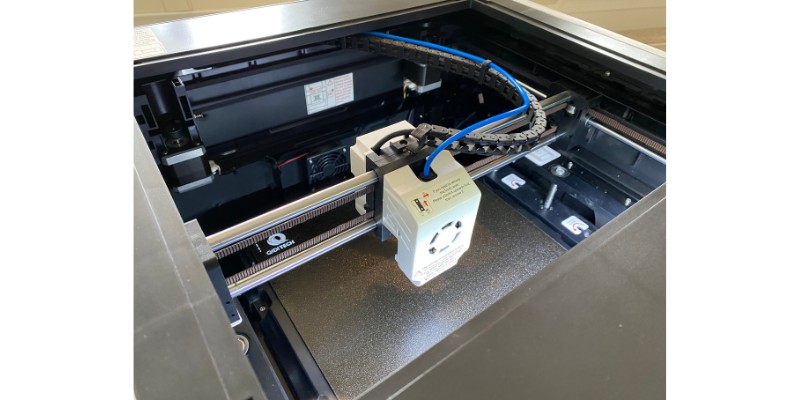

6. Snapmaker 2.0 – Best 3-in-1 FDM printer

- Price: Check latest price at Snapmaker here / Amazon here

- Build volume: A150 = 160 x 160 x 145 mm / A250 = 230 x 250 x 235 mm / A350 = 320 x 350 x 350 mm

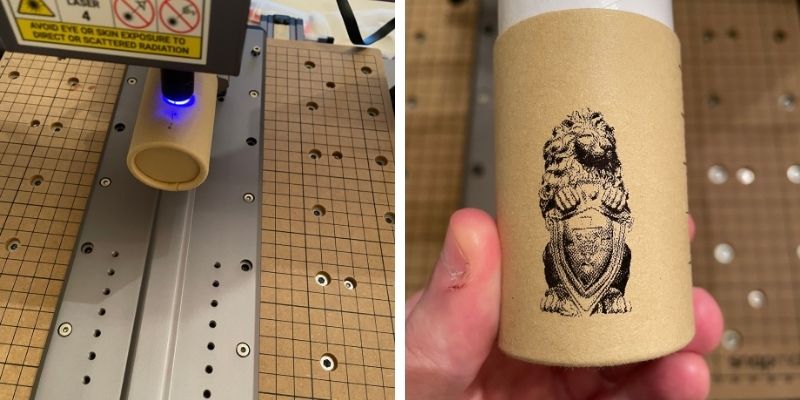

The Snapmaker 2.0 is a 3D printer and laser engraver, and can even be switched into a CNC carver — all in one machine that won’t take up your entire workshop.

We tested the Snapmaker 2.0 A350 — the largest size 3D printer version. We were impressed with print accuracy, as well as the intelligent software that dynamically adjusts print speed based on whether it’s the first few layers of your print, or further on.

The tough metal structure anchor the printer down and keeps everything stable, and you can choose to buy the Snapmaker 2.0 enclosure for better ABS 3D printing.

As a 3D printer, you can comfortably print standard filaments like PLA and ABS, as well as flexibles, with the WiFi printing a nice touch for a smoother and more efficient printing experience.

As a CNC carver, it’s all set up to carve designs on a variety of types of wood, including walnut, PCB woods, hardwoods, and other materials like acrylic and fiber sheets. If you want to use the laser engraver, you can comfortably cut and engrave images on fabrics, woods, acrylics and leather.

We also used the 4-axis rotary module add-on, which costs extra. This turns your CNC or laser head into a 4-axis turning machine, and we carved accurate chess pieces from the CNC carver and engraved our logo on a cylinder gift box with ease.

Overall, we’re hugely impressed with what the Snapmaker team have been able to develop across all three areas: 3D printing, CNC and laser cutting, and if you’re looking for a jack of all trades FDM 3D printer, the Snapmaker 2.0 could be ideal for you.

We recommend picking up the enclosure to keep yourself safe while making, as well as some spare parts for CNC. Snapmaker’s store has all these in one place, which you can visit here.

7. Ultimaker S3 – Best professional FDM printer

- Cost: $4,450 — Available on Dynamism here / Matterhackers here

- Build volume: 230 x 190 x 200 mm

Dutch FDM 3D printer manufacturer Ultimaker thoroughly deserve their position due to how excellent the Ultimaker S3 is. Featuring a dual extruder as well as being accurate up to an incredible 20 microns, the Ultimaker S3 is the perfect printer for prototyping, small business solutions, makers, and more.

You can remotely monitor your prints with its built-in camera, and print multiple high quality parts in its good 230 x 190 x 200 mm build volume. It’s also a very versatile FDM 3D printer, operable via USB stick, WiFi, or Ethernet, and is designed to look sleek — it looks like it belongs in an Apple store!

Though one of the more expensive options, the Ultimaker S3 is a fantastic printer for those who prioritize reliability, consistency, and great quality.

How FDM 3D Printing Works

The easiest way to think of FDM 3D printing works is like icing a cake with a pipe bag. Rather than with icing, melted plastic filament is pushed through the nozzle, and deposited in the set pattern. Once one layer is finished, the extruder lifts up by one layer (or the print bed moves down) and the process is repeated, as if you were icing multiple layers of a cake, gradually creating a three-dimensional object.

These plastic filaments are usually either 1.75mm or 3mm thick, and are fed via either the Bowden tube on a Bowden extruder, or directly into the 3D printer if it’s a direct drive printer, and then melted in the hot end before being extruded out of the 3D printer’s nozzle.

Filaments like PLA are fairly forgiving, but others can cause nozzle clogs if you get your temperature or other settings wrong, to pay attention to the instructions on your filament spool.

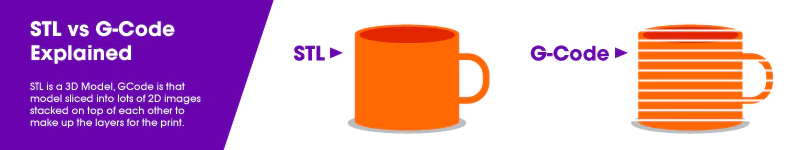

The filament is extruded, layer-by-layer, based on the 3D model supplied to your 3D printer via your slicer.

To print with an FDM printer, import your 3D file into your 3D slicer (such as Cura), slice it into each individual layer, and then send it to your 3D printer.

Your 3D printer will then deposit filament based on the dimensions of each layer, and once it’s finished each 2D layer, it moves up one, creating the next layer up, until the final model is eventually finished.

Pros and Cons of FDM Printers

Pros

Larger build volume than resin printers

Easier to set up and operate

Easier to maintain

Cheaper filament costs and more compatible materials

Little post-processing required (no curing, etc)

Broad range of applications

Cons

Print quality and level of detail doesn’t match that of resin printers

Surface finish isn’t as smooth as resin printers

Noisy

Not as productive as resin printers

Buyer’s Guide – What To Look For in an FDM 3D Printer

Print Quality

A crucial factor that determines print quality is the minimum layer height, which represents the smallest possible printable layer measured in mm. Most FDM printers gravitate around 100 microns, which is relatively standard and should suit most hobby makers. If you want better overall print quality, look for printers that drop the layer height to 50 microns, if not lower. Another important determinant of FDM 3D printing performance is XY resolution.

Other factors play into print quality, such as the quality of the printer’s parts, your chosen slicer settings, and nozzle/bed temperatures. But as a general rule, lower layer height equates to better print quality and consistency – especially in intricate and precise details.

Build Volume

Build volume refers to the maximum printable area or capacity an FDM 3D printer offers. Manufacturers list build volume in three groups of numbers measured in mm, which refer to the X, Y, and Z axis. For example, 220 x 220 x 250 mm – the size of the Ender 3 – is considered average for consumer-grade FDM printers.

Consider what type of parts and models you plan to print, and opt for a printer that matches your ambitions. If your budget allows it, it’s worth buying a printer with a capacity slightly higher than you need – in case your appetite grows for larger projects.

To give you a sense of the spread of build volume out there, we have printers such as the Prusa Mini with a build volume of 180 x 180 x 180 mm on the lower end. Then pivoting to large format 3D printers, we have towering machines like the Ender 5 Plus with a 350 x 350 x 400 mm build volume.

Another factor related to build volume to consider is the space you have available. Larger build volumes generally equate to a larger footprint. 3D printers, even the more modest machines, aren’t by no means small, and accessories can take up more space than you’d think. It’s worth finding a home for your printer before committing to a purchase and mentally assessing whether it will fit.

Bed Leveling

A 3D printer’s bed needs calibration to compensate for the unavoidable but natural height inconsistencies on the build surface. You can do this manually on many printers, but the process is quite time-consuming and can be frustrating – not to say complex – for novices.

To make this process hassle-free, you may want to consider a 3D printer with automatic bed leveling. These usually come in the shape of a probe or sensor that automatically measures the nozzle-to-bed distance across several points on the bed, then uses that data to compensate for differences during the printing process.

Filament Compatibility

3D printing filaments have different qualities – flexible, strong, easy-to-print, brittle, wear-resistant, and so on. Depending on your printing plans, it’s important to know which filament will serve you best and buy a printer that supports that material.

The most important factors are the maximum nozzle temperature if the printer has a heated bed and what temperatures that bed can reach. Filaments are very specific temperature requirements, especially high-temp exotics such as nylon and carbon fiber.

Most FDM printers generally support PLA, ABS, TPU, and PETG as standard. But, it’s important to note that while manufacturers may list filaments as compatible, especially ABS and flexibles, the machine might not play nice with them when it comes to printing good quality parts and models.

Any FDM print will do the job if you’re working with PLA. For ABS, we can’t stress how important it is to choose a printer with an enclosure to provide the stable thermal environment the material requires. For flexibles like TPU, look out for machines with direct drive extruders to limit jamming, clogging, and snapping issues that tend to flare up in Bowden systems.

Enclosure

Most FDM printers have open designs, but this isn’t suited to all filament types, especially PLA and other heat-sensitive materials that require a constant ambient temperature to perform at their best.

If you plan to dabble with these, you’ll want an enclosure, or alternatively, you may want to consider fashioning a DIY enclosure after purchase.

Extruder

Most FDM printers ship with a single extruder, the mechanism that feeds filament into the hot end. Single extruders allow you to print with one filament type or color at a time. Should you want to weave in soluble support structures made from PVA, for example, or print parts with two colors in one sitting, look out for 3D printers with dual extruders.

Printing Goals and Budget

There’s no sidestepping that 3D printers are expensive. Prices have dropped much lower than even just a few years ago, but you can expect to pay up to $300 for a decent entry-level machine. For this reason, it’s worth weighing your printing goals and needs (print size, applications, etc) against how much you’re reasonably willing to spend.

There’s little sense in a first-timer spending thousands on a professional-grade printer that offers more features than they’ll conceivably need. Conversely, a seasoned maker or small business may find a budget printer not quite able to match their plans.

What are the Different Types of FDM 3D Printers?

Though they all utilize the same technology, there are 4 main varieties of FDM 3D printer: Delta, Cartesian, Polar & Scara 3D printer (robotic arm). Polar and Scara are fairly obscure still however, so we’ll explain the main two.

Cartesian FDM 3D printers — The most common type of FDM 3D printer, Cartesian 3D printers include the legendary Ultimaker 3, and printers made by American 3D printer giant Makerbot. They use X, Y and Z-axes to extrude filament on the right co-ordinates.

Delta FDM 3D printers — Less obscure than they once were, Delta FDM 3D printers are more commonly seen in RepRap 3D printers such as the Rostock. They use three arms to control the extruder, allowing for extra flexibility and faster 3D printing.

Whereas the print bed usually moves depending on the co-ordinates in a Cartesian 3D printer, it remains stationary in a Delta printer. This is because Delta printers are more flexible and can reach the edges of the print bed, negating any need for it to move.

If you enjoyed this ranking, check out our other rankings as well as our 3D printing technology guides.

What’s Changed?

In December 2023, we changed this article substantially, including:

- Removed the Qidi Tech X-Max, Anycubic Vyper, Prusa i3 MK3S+, and Ultimaker S5. While these are all legendary 3D printers in their own right, the time has begun to catch up with them, and we’ve either added the updated versions of these into our new ranking or picked competing products over them.

Jan 2024 updates:

- Updated pricing information for 2024.

Feb 2024 updates:

- Added the Creality K1, Elegoo Neptune 4 Max, as two excellent fast FDM printers. The K1 is our overall top pick, and the Neptune 4 Max is our top pick for a budget large-format FDM printer.

Related articles:

- The best dual extruder 3D printers ranked.

- The best large 3D printers — for those who want to build larger models.

- The best DIY 3D printer kits — most are FDM printers.

- The best 3D printers under $200

- Best 3D printers under $300

- Best 3D printers under $500

- Best 3D printers under $1000