One of the major gripes with 3D printing is that many consider it slow. However, over the last few years, new tech advances in FDM and resin printing have sped up print speeds. We’ve tested the world’s fastest 3D printers in each price range to round up our top recommendations:

|

|

|

|

|

4.4

|

4.7

|

4.6

|

|

$279

|

$599

|

$470

|

|

300mm/s

|

600mm/s

|

500mm/s

|

|

220 x 220 x 250 mm

|

220 x 220 x 250 mm

|

420 x 420 x 480 mm

|

|

|

The Best Fast 3D Printers in 2024 – Reviews

| 3D Printer | Max Speed | Build volume (mm) | Max nozzle temp (°C) | Price | Where To Buy |

|---|---|---|---|---|---|

| Creality K1 | 600mm/s | 220 x 220 x 250 | 300°C | $599 | Creality here |

| Neptune 4 Max | 500mm/s | 420 x 420 x 480 | 300°C | $470 | Elegoo here |

| Bambu P1P | 500mm/s | 256 x 256 x 256 | 300°C | $699 | Bambu Lab here |

| Anycubic Kobra 2 | 300mm/s | 220 x 220 x 250 | 260°C | $279 | Anycubic here |

1. Creality K1

- Price — Check latest price at Creality here / Amazon here

- Max speed: 600mm/s

- Build volume: 220 x 220 x 250 mm

- Filament compatibility: ABS, PLA, PETG, PET, TPU, PA, ABS, ASA, PC, PLA-CF, PA-CF, PET-CF

- Max nozzle temp: 300°C

- Max bed temp: 100°C

- Connectivity: USB, WiFi

Pros

Full enclosure

Onboard camera

Extremely high speeds of up to 600 mm/s

Cons

Small build volume

Very noisy

The Creality K1 is a fully enclosed CoreXY printer. Right off the bat, you can tell where it’s going to excel: speed and stability.

While the CoreXY design helps it achieve speeds of up to 600 mm/s, you’ll have less factors to worry about while diagnosing problems thanks to the enclosure. It has an onboard camera for easy print monitoring, too.

The Creality K1 has a standard, relatively small build volume of 220 x 220 x 250 mm – like the Ender 3 has. If you want something bigger, you could opt for the K1 Max instead, with 300 x 300 x 400 mm – the same as the CR-10s.

As a slightly more expensive option for fast consumer printers (it’s a bit more than the Neptune 4, AnkerMake M5C, Qidi Tech X-Plus 3 with similar speeds), The Creality K1 works best if you want fast speeds but also love the K1’s other capabilities. Although it’s by no means a truly high-end printer, it is a slightly more expensive option.

So, if you have no plans of using finicky filaments like ABS and PETG and don’t know if you’ll really make use of the print monitoring tools, the Creality K1 isn’t worth it. But for fast printing without much hassle, it’s great.

2. Neptune 4 Max

- Price: Check latest price at Elegoo here / Amazon here

- Max speed: 500mm/s

- Build volume: 420 x 420 x 480 mm

- Filament compatibility: PLA, TPU, PETG, ABS, ASA, Nylon Filaments

- Max nozzle temp: 300°C

- Max bed temp: 85°C

- Connectivity: USB, WiFi, WLAN

Pros

Huge build volume

Pre-installed Klipper for high speed printing

Cons

Difficult to level the entire bed perfectly (although the bed mesh helps a lot)

Expect troubleshooting

The Neptune 4 Max is the printer to beat for a large build volume at a cheap price. But what people should really be paying attention to is the potential for high speed printing. This was the main thing I wanted to understand in my hands-on review of the Neptune 4 Max: in a 3D printer so large, can you really still get accurate prints at high speeds?

With Klipper coming pre-installed on the printer and the extra big fan equipment, high speeds are very much possible. They’ll shave off hours from larger prints.

The Neptune 4 Max’s build volume of 420 x 420 x 480 mm opens the doorway to multi-day prints. So, small speed improvements make for big time saves across that kind of timeline…

Unfortunately, the Neptune 4 Max’s best feature is also its main downside. To get that great build volume on a cheap printer, you should expect to spend time troubleshooting and fixing issues as they arise.

That’s doubly true when you’re pushing print speed to its limit. Although it’s not impossible for a beginner, it’s definitely a better choice for someone familiar with 3D printing and ready to dive into Klipper, input shaping, etc.

3. Bambu P1P

- Price: Check latest price at Bambu Lab here

- Max speed: 500mm/s

- Build volume: 256 x 256 x 256 mm

- Filament compatibility: PLA, PETG, TPU, PVA, PET, and with enclosure PA, PC, ABS, ASA

- Max nozzle temp: 300°C

- Max bed temp: 100°C

- Connectivity: USB, WiFi

Pros

Easily customizable

Stable and consistent printing

AMS compatibility

Cons

Lacking features by default (enclosure, camera, touchscreen)

Expensive for a barebones Carbon X1

The Bambu P1P is like a stripped down version of the popular Carbon X1. It doesn’t have the camera or the enclosure (unless you buy them as add-ons), but it does have a CoreXY design that speeds things up. It can print at a maximum of 500 mm/s.

A high max nozzle temperature and the potential for an enclosure makes the Bambu P1P a similarly reliable and consistent option to the Creality K1. It comes with the Bambu Lab slicer, auto leveling, and even AMS compatibility for multi-color printing, but no touchscreen.

Although many exclusive slicers fail to be as useful as the free options, Bambu Lab’s slicer actually proves to be very useful by providing a huge number of presets.

A major problem with high speed printing is the amount of tinkering necessary to achieve them. The Bambu P1P can get you there, without you needing to mess with firmware configs, cheap and unreliable printers, or complicated upgrades.

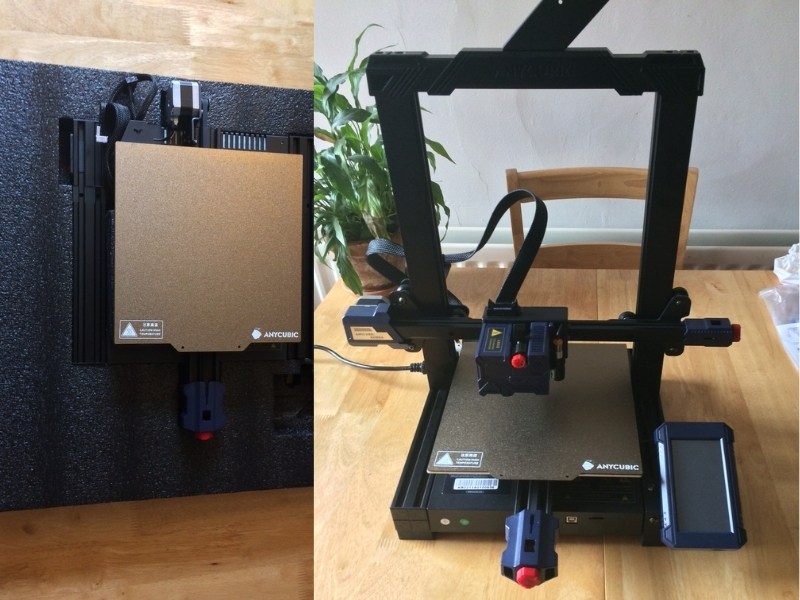

4. Anycubic Kobra 2

- Price: Check latest price at Anycubic here / Amazon here

- Max speed: 300mm/s

- Build volume: 220 x 220 x 250 mm

- Filament compatibility: PLA, PLA+, TPU

- Max nozzle temp: 260°C

- Max bed temp: 110°C

- Connectivity: MicroSD

Pros

Very cheap

Solid quality of life features (auto leveling, WiFi, touchscreen)

Cons

Limited filament options

On the slow end of high-speed printing

The Anycubic Kobra 2 is a true budget machine, but it still offers significantly faster print speeds than other printers in its price range. Its maximum is 300 mm/s.

It doesn’t reach those speeds using a CoreXY design or offering Klipper. The Kobra 2 just has a quality extrusion and cooling system, so you can safely reach higher speeds. Notably, it uses a direct drive extruder and a rapid cooling system.

Although it doesn’t cost much compared to other printers on this list, it does still have WiFi, auto-leveling, and a touchscreen. The main negative of the Kobra 2 is that you will be stuck with subpar speeds– at least, in the realm of high speed printing. There’s upgrade potential so you could change that, but it isn’t impressive by default.

If you’re willing to put in some extra effort to reach higher speeds and you’re on a strict budget, the Anycubic Kobra 2 is pretty much perfect. But if you can afford something better, it will serve you well.

How Speed Works in 3D Printers

Printer Format

Printer format is the factor in print speed that’s the hardest to change— you’re stuck with whatever type of printer you’ve purchased.

The Cartesian FDM printer type is the one people usually think of when they imagine a 3D printer. However, there are other variations that can really up the speed of your prints.

A good example is CoreXY. They’re becoming increasingly mainstream because they have such few downsides, but can reach higher speeds.

As the name implies, the X and Y motors on a CoreXY printer are fixed. These printers have a relatively low part count and a light, hyper mobile print head. Bambu’s printers, as well as the Creality K1 and Qidi Tech X-Plus run these CoreXY systems. You can read more about these in our guide to the top coreXY printers.

They are usually contrasted by the typical bed slinger design, which moves the bed back and forth during the printing process.

Another less popular type of FDM printer is the Delta printer. They’re easy to differentiate because of their triangular shape, which is also the reason they can reach higher speeds. You can read more about these in our guide to the top delta printers.

Although Delta and CoreXY printers are designed to be faster, that doesn’t mean you need one to hit high speeds. There are a ton of other factors that impact printer speed, too.

In this article alone, I mention multiple 3D printers that aren’t Delta or CoreXY – like the Kobra 2, and the Neptune 4 Max.

Printer Equipment

If you want speed and you want it ASAP, nozzle size might be the way to go. Most 3D printers have a default nozzle size of 0.4 mm, but you can find 0.6 mm, 0.8 mm, or even larger nozzle sizes for purchase.

Swapping out your nozzle for something bigger and pairing it with a corresponding larger layer height can immediately double your print speeds. The caveat is that you sacrifice some print quality.

Although upping nozzle size only works for non-precise, non-decorative pieces, there are other printer features that assist with speed in every situation. They just don’t do it as directly.

Quality heating components are pretty much a necessity for high print speeds because the filament won’t heat up quickly enough otherwise. Poor heating can also cause issues with filament viscosity.

Similarly, cooling components need to be just as quality to match the breakneck speeds or you risk print errors.

Firmware

Many older (and some modern) 3D printers use Marlin by default as their firmware. It’s not the best for making config changes, and it has certain limitations when it comes to speed.

Klipper is the firmware of choice for anyone who wants those two benefits. You can swap Marlin out for Klipper, but some printers even come with it pre-installed.

The easier config changes make the fine tuning process faster, which is the first step to getting better print speeds. Another key feature is input shaping— in essence, it’s a way to minimize vibrations and the corresponding ringing that happens at super high speed 3D printing.

One of the biggest changes between Klipper and Marlin is the fact that Klipper can run g-code faster. Even with no config changes, Klipper will let your hardware shine rather than slowing your printer down because of the g-code bottleneck.

It’s important to understand that Klipper on its own won’t automatically make your printer fast. You need to use the tools Klipper gives you to make the most out of your printer.

Slicer Software

The free way to instantly up your print speed is to simply change settings in your slicer software. You can do this no matter what slicer you use, and no matter what printer you own.

Usually, changing infill and wall thickness settings to use less filament gets you quick results with little chance of failure.

If you’re ready to increase speeds beyond that, you’ll need to consider settings like acceleration, jerk, temperature, and fan settings.

You’ll probably want to tweak things slowly with an easy benchmarking print, like a Benchy. Make sure you’re compensating for temperature and vibrations as you go.

So, Do You Really Need a Super Fast 3D Printer?

Although speed is an increasingly popular marketing gimmick for 3D printers, sometimes it’s just that— a gimmick. Not everyone needs a fast 3D printer or will put that speed to use.

If you enjoy the engineering process of getting your printer to work at insane speeds, then that’s reason enough to pursue it from a hobby perspective. But if you’re doing it for the sake of practicality, you should rethink your pursuit of speed.

You often will need to make the choice between quality and getting your printer that much faster. Quick printing will always make it harder to assure quality, and unless you really don’t care how your prints come out, it might not be worth the time and monetary investment.

For FDM 3D printers, some materials become volatile and print with imperfections if you don’t slow right down, like PEEK, PC, and others. Printing at 150mm/s+ would just ruin your prints, so the speed is useless here.

Instead of purchasing products or printers that are designed to be faster, try doing some basic changes in your software. It will make printing a little more efficient, without the effort, money, and inconsistency that comes with the fast printing package.

Related articles:

- Best large resin 3D printers (bigger = faster!)

- Best FDM 3D printers

- How long does 3D printing take?

- Best 3D Print Speed Settings for Every Filament

- Check the best print speed settings for Ender 3