FDM 3D printers have been around since the late 1980s, and they’re the most commonly used and most affordable 3D printers for hobbyists. There’s many different types now, from standard Cartesian printers to super-fast CoreXY variants and even conveyor belt printers using FDM technology.

Quick Overview

Here are the main types of FDM 3D printers, and the main differences between them:

- Cartesian 3D printers: The most common and reliable type, using X, Y, and Z coordinates to move the print head or bed. Good for print quality and flexible filaments.

- Delta 3D printers: A faster and taller type, using a circular print bed and a triangular print head that can move in any direction. Good for speed and large parts.

- CoreXY 3D printers: A much faster version of standard Cartesian builds using belts and pulleys with the two X and Y motors working together.

- Polar 3D printers: A more efficient and compact type, using a polar coordinate system and a circular print bed that rotates and lifts. Good for saving space and energy.

- Belt 3D printers: Use a conveyor belt to offer unlimited-length 3D printing.

- Scara 3D printers: Use a robotic arm that can print in any direction and location, mostly used for complex geometries and industrial projects like concrete house building.

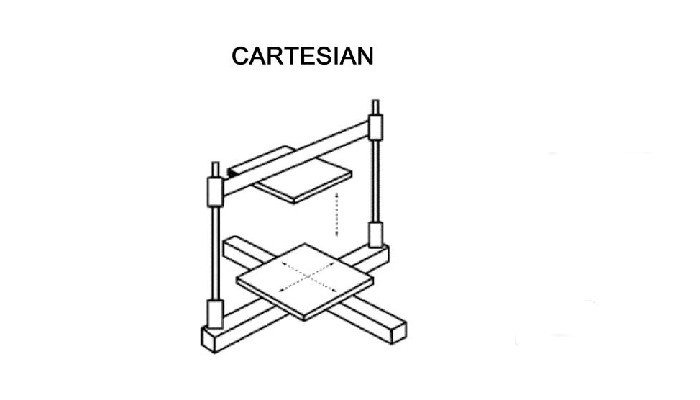

1. Cartesian 3D Printers

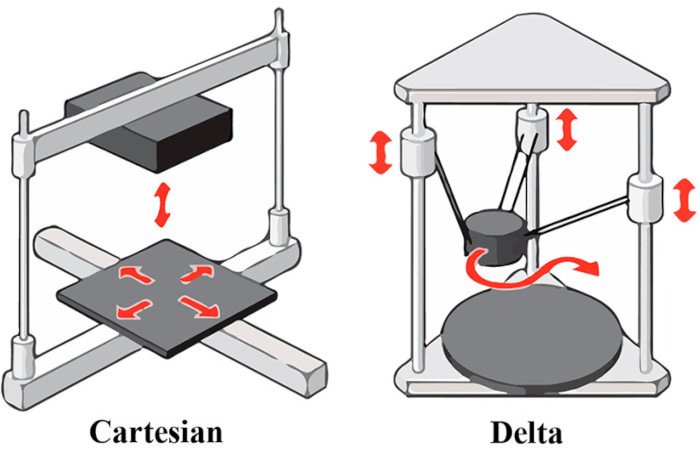

Cartesian 3D printers, named after the Cartesian coordinate system they use, are the most common FDM printer type. They operate by moving the print head or bed along the X, Y, and Z axes to deposit the plastic filament.

Usually, the print head moves on the X- and Y-axes, whilst the print head or bed moves up and down on the Z-axis. Some 3D printers move the extruder up and down for each layer, whereas some Cartesian 3D printers have the print bed move up and down instead.

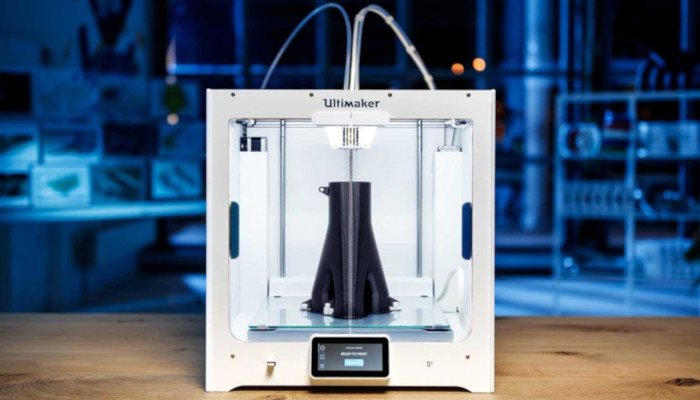

They are simple, reliable and can be easily disassembled and upgraded, leading to a number of excellent 3D printer kits being developed, such as the popular Ender 3 range, as well as kits by Prusa, Anycubic, Sovol, and Elegoo. Prosumer 3D printer companies have also built Cartesian FDM 3D printers, including UltiMaker, Raise3D, Intamsys, Markforged, Voron, Bambu Labs, and many more.

Notable Printers

Advantages

- Simplicity and Reliability: Cartesian 3D printers have a straightforward design, making them reliable and easy to use, especially for beginners.

- Wide Availability of Parts and Knowledge: Given their popularity, there is a wealth of knowledge, community support, and readily available parts for Cartesian printers.

- Consistent Print Quality: These printers generally provide consistent print quality across the entire build area due to the uniform movement on the X, Y, and Z axes.

- Versatility in Material Use: Cartesian printers are capable of printing with a wide range of materials, including flexible filaments, due to their stable extruder design.

Disadvantages

- Limited Print Speed: Unless they have a CoreXY system, they’re slower to print than Delta printers, due to the weight of the moving parts, especially on the X and Y axes. When operating at higher speeds, Cartesian printers can also suffer from vibrations due to the heavier print head or bed.

- Larger Footprint: The rectangular or square frame of Cartesian printers can take up more space compared to more compact designs like Polar or Delta printers.

- Potential for Reduced Accuracy Over Time: The belts and linear bearings in Cartesian printers can wear over time, potentially reducing accuracy if not properly maintained.

2. Delta FDM 3D printers

Delta 3D printers have a circular print bed with a 3D printer extruder featuring three fixed triangular points. Each of these three points can move both upwards and downwards within the cylinder print structure, to place the print head where it needs to be to print.

The main reason to use a Delta 3D printer is speed. They can 3D print much faster than most Cartesian printers (except newer CoreXY variants, which we’ll cover further in this article).

The major difference between Delta and Cartesian printers is where they can print compared to where the print bed is. For example, in a Cartesian 3D printer each part can only move in one direction — a certain distance down each axis. However, within a Delta 3D printer, the print head is more flexible and can move in any direction.

Delta printers are generally slim and tall, making them useful for some architectural prints, and tall figurines.

However, they can lose accuracy towards the edges of the print area, and Cartesian printers are considered slightly more accurate and stable. Because Delta printers use a bowden extruder, they’re considered worse for printing flexibles like TPU.

Notable Printers:

- Flsun Super Racer

- Flsun V400

- WASP Delta 2040 Pro

Advantages

- Speed: Delta printers are known for their high speed, capable of moving and printing faster than most Cartesian printers.

- Height Advantage: With their tall and slim design, Delta printers can handle taller prints, which is beneficial for specific applications like architectural models or tall figurines. They’re also generally good for handling larger parts for use in prototyping and art installations.

Disadvantages

- Complex Calibration: Setting up and calibrating a Delta printer can be more complex than with Cartesian printers.

- Accuracy Issues at Edges: While Delta printers are generally accurate, they can lose some precision towards the edges of the print area, which could be a concern for projects requiring uniform precision.

- Flexibility Limitations: The use of a bowden extruder in many Delta printers makes them less ideal for printing with flexible materials like TPU compared to direct drive systems.

3. CoreXY 3D Printers

CoreXY 3D printers use a belt-driven control system to precisely move the print head or build plate along the X and Y axes. They’ve been around since 2012, but only recently came to dominate desktop 3D printing with the releases of Bambu Labs 3D printers, and the Creality K1.

Unlike traditional Cartesian systems where each motor is responsible for moving one axis independently, CoreXY employs two motors working together to control both the X and Y axes simultaneously.

These two motors are mounted at different locations, typically at opposite corners of the 3D printer frame. These motors are connected via a system of belts and pulleys to the moving parts of the printer. The belts allow for precise and synchronized movement, maintaining print quality at faster print speeds.

This YouTube video from Vector 3D demonstrates CoreXY motion using two pieces of paper and a real CoreXY printer:

Notable 3D Printers:

- Creality K1

- Qidi Tech X-Plus 3

- Tronxy X5SA

- Voron 3D printer range

You can read more about these in our guide to the top CoreXY printers available.

Advantages

- High Speeds: CoreXY systems can achieve faster print speeds due to the coordinated movement of two motors, reducing the overall weight of the moving components. Quicker directional changes also lead to smoother printing.

- Precision and Accuracy: The precise control over the print head or build plate that the synchronized movement of motors in CoreXY systems leads to improved print accuracy and quality.

Disadvantages

- Complex Design & Maintenance: The CoreXY system involves a more intricate mechanical setup with belts and pulleys, making the printer design more complex compared to some other motion systems. This can make them more difficult to maintain, with more components that need replacing or adjustment.

- Calibration Challenges: Achieving optimal performance requires precise calibration of the belts and motors, which can be challenging for beginners.

- Cost: CoreXY 3D printers can be more expensive due to the additional hardware and components required for the dual-motor, synchronized movement system.

4. Polar 3D Printers

Polar 3D printers use a polar coordinate system, where the print head moves in a radial and angular direction, rather than the linear motion used in Cartesian systems.

In a polar system, every other point on the print bed is determined by its position compared to the central point in the middle of the print bed. Each point is not a nominal place, but is relative to this central point. Polar 3D printers use circular print beds that rotate and lift up and down.

Polar 3D, a polar 3D printer that debuted at CES a few years back.

Polar 3D printers require just two motors to print, working with just angle and length in calculating print areas, whereas Cartesian and Delta printers typically require 3 motors to power each axis. Because Polar printers are simpler, with fewer moving parts, this can lead to lower maintenance.

Notable Printers

- Polar 3D

- Sculpto PRO2

Advantages

- Compact: The unique L-shaped design of Polar 3D printers offers a compact footprint, making them ideal for limited spaces.

- Fewer Moving Parts: With typically just two motors needed, Polar 3D printers have fewer moving parts compared to Cartesian and Delta printers. This can result in less wear and tear and lower maintenance needs.

- Ideal for Certain Shapes and Designs: The polar coordinate system is especially efficient for certain designs, like circular or radial parts, allowing for smooth and continuous printing without the stop-and-start movements common in other FDM printer types.

Disadvantages

- Limited Build Volume: The circular print bed restricts the build volume to its diameter, which can be a limitation for projects requiring larger, square printing areas.

- Varying Print Speed and Quality: The print quality can vary at different points on the print bed due to changes in the extruder’s speed, potentially affecting the consistency of prints.

5. Belt 3D Printers

Belt 3D printers, also known as continuous or infinite 3D printers, use a conveyor belt or continuous motion system instead of having a static build platform.

They use a moving belt to continuously feed the printed object away from the print head. This allows for the printing of objects with unlimited lengths, or the continuous production of multiple objects.

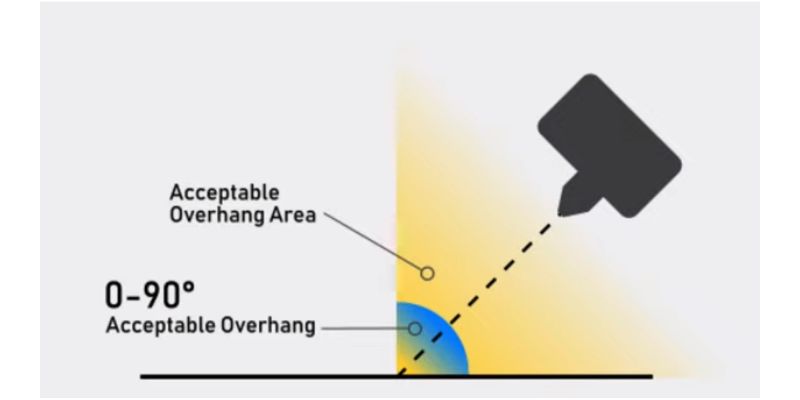

Belt 3D printers print at an angle, allowing you to print overhangs greater than 45°, which traditional FDM printers are limited to. This is because the belt keeps moving during printing while the print head is angled at 45°, allowing it to add steep layers diagonally. However, these overhangs have to be in the direction of the Y-axis.

Notable 3D Printers:

- Creality CR-30 3DPrintMill

- PowerBelt3D

For a full list of these belt printers, I recommend reading our full round-up of the top belt 3D printers.

Advantages:

- Continuous Printing: Belt 3D printers enable continuous printing of objects with unlimited lengths, at least in theory. They have a detachable bracket that extends outside the build, preventing a long print from falling off the printer during printing. This makes them suitable for creating long objects such as swords for cosplays.

- Batch Printing: The continuous motion system allows for the simultaneous printing of multiple objects on the same belt, without needing to keep removing prints from the print bed to start the next project.

- Reduced Need for Supports: Objects with overhangs and complex geometries may benefit, reducing the need for supports compared to traditional FDM printing.

Disadvantages:

- Limited Z-Axis Resolution: Belt 3D printers aren’t ideal for high prints on the Z-axis, but this can be overcome by printing the object on its side to take advantage of the unlimited-length printing.

- Material Compatibility: The belt material affects compatible filaments you can print with, as not all filaments will adhere to the belt material.

- Complex Mechanics: The more complex continuous motion system makes these printers more challenging to build and maintain, and the slicers are different.

6. SCARA / Robotic Arm 3D Printer

SCARA 3D printers (Selective Compliance Assembly Robotic Arm) use a robotic arm to 3D print.

Most Scara 3D printer applications are in the 3D printing of houses and other industrial projects. This is because for printing huge structures, like houses, you need to be able to move the house 3D printer to the location.

Cartesian and delta 3D printers have structures around them, making them more difficult to transport, robotic arm printers are not fixed to a print plate, and therefore are more versatile and mobile. This also makes it easier to print geometrically complex parts with Scara printers, as they move in the most similar way to human hands.

Notable 3D Printers:

- RepRap Morgan

- Dobot 3D printer

- Most construction house-building 3D printers, such as those by Apis Cor

Advantages

- High Precision and Flexibility: SCARA robotic arms offer a greater range of motion compared to traditional 3D printers, making them ideal for complex geometries and intricate designs.

- Efficient for Large-Scale Projects: These printers excel in large-scale projects, such as building components or large sculptures. Their mobility and ability to print at various angles make them suitable for projects that are beyond the capability of stationary printers.

- Can Use in Different Print Environments: SCARA printers can operate in various environments and on different scales, from small, detailed items to large construction projects.

Disadvantages

- High Cost: SCARA 3D printers are generally more expensive than other types of FDM printers.

- Complex Operation and Maintenance: Operating and maintaining a robotic arm printer requires significant technical expertise. These printers often require more space due to their size and the range of motion of the robotic arm.

- Limited to Specific Applications: While excellent for certain tasks, SCARA printers are not as versatile for general 3D printing needs.

If you’re still not completely sure, we have a bunch of other great guides and rankings to help you choose, including:

- Every different type of 3D printer

- Best FDM 3D printer

- Best dual extruder 3D printer

- Our favorite 3D printers overall.

- The best online 3D printing services

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more