While they used to be only industrial 3D printers, metal 3D printing is now becoming cheap and accessible enough for use in far lower cost rapid prototyping — thanks to companies like Desktop Metal. This has wide-ranging effects in areas such as classic car parts which are no longer in production, aerospace, space, 3D printed jewelry, and even in the creation of 3D printed guns.

But how will metal 3D printing change the world for the average person?

- Note: you may instead be looking for our ranking of the best metal 3D printers.

If you’re interested in purchasing a metal 3D printer, we can advise you based on your specific needs:

*One of our trusted partners will be in touch following a quote request.

Metal 3D Printing & Metal 3D Printers: Changing Manufacturing

There are a number of metal 3D printing technologies which have been around for many years. These include perhaps the most notable, Direct Metal Laser Sintering, or DMLS. This is similar to Selective Laser Sintering in terms of process, though DMLS involves 3D printing metals such as stainless steel and cobalt-chrome, whereas SLS uses plastics such as Nylon.

Other metal 3D printing technologies such as Electron Beam Melting, Binder Jetting, and Directed Energy Deposition are also used however.

These technologies are helping improve our daily lives in a variety of ways. Firstly, custom metal parts on rockets and planes are an improvement on typically manufactured parts as they can be printed lighter and stronger. This reduction of weight is critical for cutting costs in an industry where removing one olive from each salad served to passengers can save an airline $100,000 per year.

Therefore, we listed 10 metal 3D printer startups and companies who are changing metal 3D printing.

1 – Concept Laser

- Metal 3D Printing Technology: DMLS

- Company based: Germany

- Notable metal 3D printer: Concept Laser X Line 2000R

Concept Laser are a German metal 3D printer manufacturer founded back in 2000 by Frank Herzog. Since then, GE acquired 75% of Concept Laser in December 2016 and the company now operates under the GE Additive umbrella. Concept Laser focus on creating metal 3D printers which utilize Direct Metal Laser Sintering technologies, a process similar to Selective Laser Sintering.

The German metal 3D printer company currently sell six printers, including the very notable X Line 2000R machine. This huge metal 3D printer can print structures up to a maximum size of 800 x 400 x 500 mm, and is claimed to be the largest metal 3D printer in the world!

2 – Arcam

- Metal 3D Printing Technology: EBM

- Company based: Sweden

- Notable metal 3D printers: Arcam A2X

Arcam are a Swedish metal 3D printer manufacturer, who like Concept Laser were acquired by GE and reside under the GE Additive umbrella. Arcam was founded in 1997 and has since expanded to have offices in the United States, Italy, China, and the UK.

Unlike its competitors, Arcam uses Electron Beam Melting (EBM), a 3D printing technology which uses an electron beam rather than a laser to melt metals. Arcam is currently the only metal 3D printer manufacturer to commercialize this technology and is the only company selling these 3D printers.

3 – Xact Metal

- Metal 3D Printing Technology: DMLS

- Company based: USA

- Notable metal 3D printers: XM200 & XM300

Xact Metal is an American 3D printer startup which operates out of Penn State University’s Innovation Park. Founded by Matt Woods, Xact Metal sells metal 3D printer machines which utilize powder bed fusion technologies to create strong metal parts.

Focused on enabling manufacturers to 3D print metal at the lowest possible prices, Xact Metal has so far released three metal 3D printers. These include the XM200C, XM200S, and XM300C. These range in price from the cheapest XM200C retailing at $80,000, to the XM300C ranging from $175,000 to $275,000 depending on the add-ons. The printers can print materials including stainless steel, cobalt-chrome, and even bronze!

4 – Sciaky

- Metal 3D Printing Technology: Direct Energy Deposition (DED)

- Company based: USA

- Notable metal 3D printer: EBAM 300

When you think about metal 3D printing, you undoubtedly consider it a new, modern technology. Sciaky however have been around for a very long time prior to 3D printing, having been established in 1939 (just before the start of World War 2!). Since then, Sciaky have optimized Directed Energy Deposition technologies to release their five metal 3D printers they currently sell.

These metal 3D printers aren’t however desktop machines you can just pick up and carry around. These are industrial 3D printers, room-sized behemoths that require warehouses to house them. Most notably, Sciaky’s EBAM 300 metal 3D printer has chamber dimensions of 300″ x 108″ x 132″, which is absolutely huge.

5 – ExOne

- Metal 3D Printing Technology: Binder Jetting

- Company based: Germany

- Notable metal 3D printer: ExOne M-Flex

ExOne are a German metal 3D printer manufacturer founded in 2005 as a spin-off company of Extrude Hone Corporation. The original company has used metal 3D printing since 1996, and sand 3D printing since 1999 however.

ExOne use Binder Jetting technologies which makes them stand out as this is a very rarely used technology. Using this technology, ExOne currently sell six metal 3D printers ranging from their Exerial printer to their S-Print and M-Print series of printers.

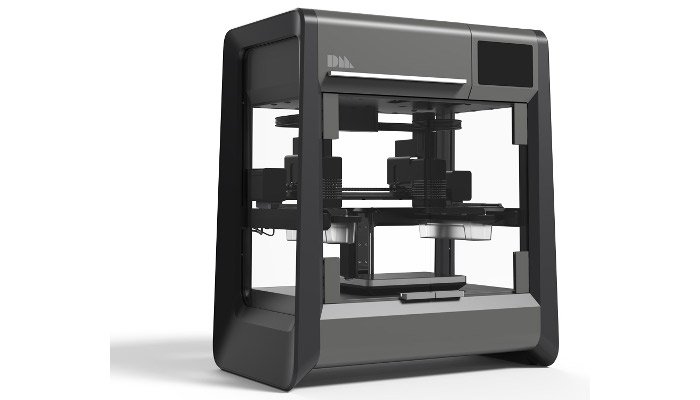

6 – Desktop Metal

- Metal 3D Printing Technology: Bound Metal Deposition

- Company based: USA

- Notable metal 3D printers: Studio and Production System

Desktop Metal are an American startup which has raised over $277M in investment so far, from companies including Google, BMW, Ford, GE, and more. Since being founded back in 2015 by CEO Ric Fulop, Desktop Metal has expanded to hire over 160 people.

Their metal 3D printing technology, Bound Metal Deposition, is very similar to Fused Deposition Modeling. Desktop Metal have utilized this technology in their two metal 3D printer machines, the Studio and Production Systems. The first machines are being shipped at the moment to a variety of customers who paid around $120,000 for each Studio System, and $320,000 for a Prodution System.

7 – Markforged

- Metal 3D Printing Technology: ADAM

- Company based: USA

- Notable metal 3D printer: Metal X

Markforged have grown to become a huge player in the 3D printing industry very quickly due to their competitive advantage: carbon fiber 3D printing. This has allowed the American metal 3D printer manufacturer, started up by Greg Mark in February 2013, to offer parts up to 23x stronger than typical FDM parts. This is due to carbon fiber being interwoven within the PLA or ABS extruded when printing.

Since conquering the FDM 3D printer market, Markforged have set their sights on releasing their first metal 3D printer. This impressive machine, the Markforged Metal X, uses their patented ADAM (Atomic Diffusion Additive Manufacturing) technologies to create metal parts at a very low cost. The Metal X is also far cheaper than most industrial metal 3D printer machines, retailing at $100,000.

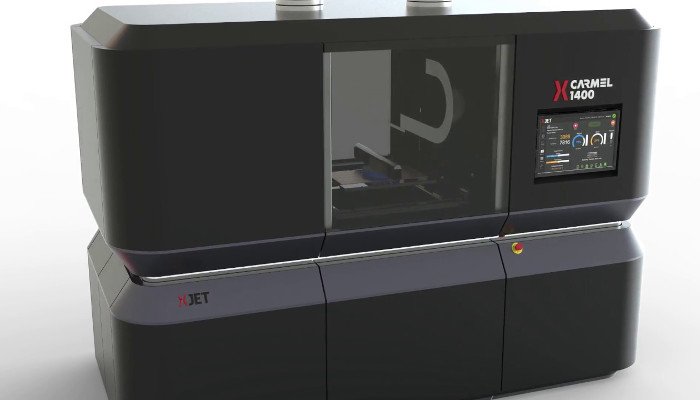

8 – XJet

- Metal 3D Printing Technology: NanoParticle Jetting

- Company based: Israel

- Notable metal 3D printer: Carmel 1400

XJet are an Israeli metal 3D printer manufacturer who use their patented NanoParticle Jetting technology in their two metal 3D printing systems. The technology has been carefully cultivated since XJet was founded in 2005, and is now poised to offer low cost metal 3D printing to save companies money.

XJet’s NanoParticle Jetting technology isn’t too dissimilar from Binder Jetting that ExOne use. Both involve particles being jetted onto a build tray. As a result, XJet have released two metal 3D printer systems, the Carmel 700 and Carmel 1400. Overall, XJet are a very innovative manufacturer who are making much noise in metal 3D printing.

9 – Vader Systems

- Metal 3D Printing Technology: Liquid Metal Printing

- Company based: USA

- Notable metal 3D printer: Polaris

Vader Systems are a very interesting company. Formed of a father-son team focused on delivering metal 3D printing at the highest quality, Vader Systems developed their Liquid Metal 3D printing and Magnet-o-Jet technologies within their metal 3D printers. This involves propelling liquid metal from a chamber at scorching temperatures of 1200°C to create parts. The process uses print nozzles similar to a two-dimensional inkjet printer, drawing some parallels.

Vader Systems have so far released their Polaris system, Magnet-o-Jet subsystem, and their Ares system. Each designed to specialize in different tasks, Vader Systems have a versatile and innovative range of metal 3D printer systems. Definitely one to watch for the next few years.

10 – 3D Systems

- Metal 3D Printing Technology: Direct Metal Printing

- Company based: USA

- Notable metal 3D printer: ProX DMP

The original 3D printer company, 3D Systems launched their first printer based on stereolithography back in the late 1980s. Now 30 years later and still going strong, 3D Systems entered the metal 3D printer market in 2013. With $600M in annual revenue and thousands of staff, 3D Systems control the Direct Metal Printing market (a process which is similar to Direct Metal Laser Sintering).

Despite being a giant in the 3D printing industry, 3D Systems’ venture into the metal 3D printer market wasn’t as you’d expect. Rather than develop their own metal 3D printer systems, they acquired French company Phenix Systems who did produce metal printers. Using Phenix’s expertise, 3D Systems have since expanded their range and cemented themselves in the metal 3D printing market.

11 – EOS

- Metal 3D Printing Technology: Direct Metal Laser Sintering

- Company based: Germany

- Notable metal 3D printer: EOS P 500

EOS are a German industrial 3D printer company with a rich history in the industry. Formed back in 1989 to take advantage of the burgeoning Selective Laser Sintering industry, EOS was serving clients such as Mercedes-Benz and BMW during the 1990s before focusing on metal 3D printing, namely Direct Metal Laser Sintering.

Following the first DMLS metal 3D printer released in 1995, EOS began servicing a far broader range of clients and controlled the DMLS industry – until recently where competitors including Xact Metal, 3D Systems and Desktop Metal emerged. This specialization in DMLS allowed EOS to grow into the successful company it is today, employing over 930 employees in total.

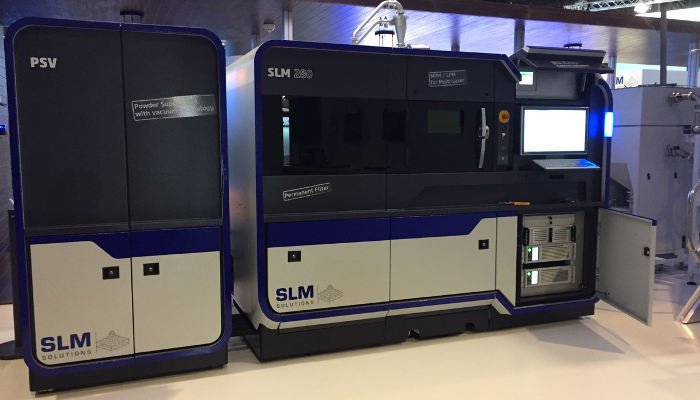

12 – SLM Solutions

- Metal 3D Printing Technology: Direct Metal Laser Sintering

- Company based: Germany

- Notable metal 3D printer: SLM 800

Like EOS, SLM Solutions is an German metal 3D printer manufacturer that operates in the DMLS/SLM sector. Founded in 2006, SLM have a stellar reputation for delivering some of the highest quality metal 3D printers around, with a product list that ranges from the SLM 125 for medium priced endeavors; to the large SLM 800 for large-scale industrial printing.

With a clear focus on innovation and bringing new metal 3D printer materials to the market, SLM Solutions have experienced great success during the last decade. The company supplies companies in the aeronautic, medical and automotive sectors, providing a range of metal 3D printer services.

13 – Nano Dimension

- Metal 3D Printing Technology: Inkjet Deposition

- Company based: Israel

- Notable metal 3D printer: Dragonfly Pro

Nano Dimension are a company that has until recently flown under the radar, with attention being focused on their exciting Dragonfly Pro 3D printer. The Dragonfly has everyone excited as it can 3D print polymers and metals simultaneously, with wide applications for electrical engineers as well as the defense sector. Though the company has only been around since 2012, the progress Nano Dimension has made already suggest that it has a bright future in the metal 3D printer industry.

14 – Voxeljet

- Metal 3D Printing Technology: Binder Jetting

- Company based: Germany

- Notable metal 3D printer: VX4000

Voxeljet pushed the boundaries of engineering capabilities when designing the VX4000. It is a giant; an engineering behemoth – with a maximum print volume of 4,000 x 2,000 x 1,000 mm! This naturally drew our attention towards Voxeljet, who are one of the few metal 3D printer companies to focus on Binder Jetting.

Despite only being founded in 1999, within three years Voxeljet had supplied their sand and metal 3D printers to clients such as BMW and Daimler in Germany. Not just a metal 3D printer, Voxeljet 3D printers also print sand molds, displaying their versatility.

15 – Renishaw

- Metal 3D Printing Technology: Direct Metal Laser Sintering

- Company based: UK

- Notable metal 3D printer: RenAM 500M

A British company with business globally, Renishaw are a pioneer not just in metal 3D printing, but in a range of other industries including aerospace, medical, scientific and automotive sectors. Within metal 3D printing, Renishaw focus on metal powder bed technologies, with the ability to 3D print titanium alloys, cobalt chromium, stainless steel, and a host of other metals. Now with four 3D printers ranging from the AM250 to the RenAM 500Q, Renishaw have metal 3D printer systems for all areas of manufacturing.

16 – Digital Metal

- Metal 3D Printing Technology: Binder Jetting

- Company based: Sweden

- Notable metal 3D printer: DM P2500

Digital Metal is one of two Swedish metal 3D printer companies that make our list, the other being EBM 3D printer manufacturer Arcam. The company is another – along with ExOne and Voxeljet – to incorporate Binder Jetting technologies into a metal 3D printer; though Digital Metals focuses on metal 3D printing rather than also printing with sand-based materials.

As part of Höganäs AB, the world’s largest producer of powdered metals, Digital Metal is certainly well supported. The multinational has been in operation in 1797, founded by Count Eric Ruuth, and is perfectly stationed to supply Digital Metal with metal powders to incorporate into their 3D printer solutions. For this reason, we predict strong progress and expansion for Digital Metal in the future.

17 – Optomec

- Metal 3D Printing Technology: Direct Energy Deposition

- Company based: USA

- Notable metal 3D printer: LENS 450

Optomec is an American company which, like Sciaky, focuses on Direct Energy Deposition. This interesting metal 3D printing technology, sometimes referenced to as 3D cladding, has been implemented into Optomec metal 3D printers since their first LENS solution in 1998.

Based in Albuquerque, New Mexico, Optomec have already received over $6M in investment to expand their metal 3D printer range, now employing over 50 staff members. Though not as well known as Direct Metal Laser Sintering, DED technologies present an interesting alternative to printing metal, to which Optomec are at the forefront.

18 – Trumpf

- Metal 3D Printing Technology: Direct Metal Laser Sintering

- Company based: Germany

- Notable metal 3D printer: TruPrint 3000

Another metal 3D printer manufacturer based in Germany, Trumpf specialize in industrial DMLS 3D printers, though they also operate in a variety of other sectors too, similar to Renishaw. Trumpf’s innovations has resulted in the product line of five metal 3D printers, including three that utilize Laser Metal Fusion, and two that use Laser Metal Deposition.

Both of these technologies involve metal powders and a laser, though the process of application is different. In Laser Metal Fusion, a hybrid of DMLS, a laser is used on a powder bed filled with metal powder, heating up and solidifying the powder in each layer to create a fully-formed metal part. In Laser Metal Deposition the laser is used more as a welder, adding additional layers of metal powder to the part as it stands, rather than in a powder bed.

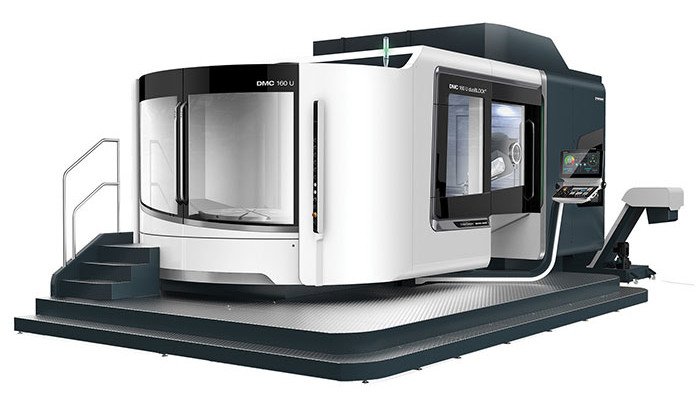

19 – DMG Mori

- Metal 3D Printing Technology: Direct Metal Laser Sintering

- Company based: Germany / Japan

- Notable metal 3D printer: Lasertec 4300

Born from a collaboration between German and Japanese firms, DMG Mori are not only involved in the additive manufacturing and 3D printing sector, but also in industries such as CNC milling. The company, like Trumpf, offers two different metal 3D printer technologies: those that involve a powder bed (DMLS/SLM); and those that involve a powder nozzle (DED).

What sets DMG metal 3D printers apart from the crowd is that these printers, such as the Lasertec 4300 3D hybrid, are not only a 3D printer but also a CNC milling machine, all rolled into one. These machines are therefore the all-in-one solution to certain manufacturing needs; a very interesting concept.

20 – Cytosurge

- Metal 3D Printing Technology: FluidFM Micro 3D printing

- Company based: Switzerland

- Notable metal 3D printer: FluidFM µ3Dprinter

Cytosurge is the only Swiss metal 3D printer company on this list, and is definitely one of the most innovative and unique. Though 3D printers are getting more and more accurate, with smaller and smaller layer sizes and resolutions being developed, Cytosurge’s technology allows for phenomenally accurate 3D printing on the scale of just a few nanometers.

Though the Swiss company doesn’t just operate in the 3D printing industry – also operating in industries including bioscience – Cytosurge’s FluidFM 3D is an extraordinary machine. With the ability to print metal structures with such accuracy, this opens a number of doors for creating parts that could not previously be made.