3D printing meat combats both the cruelty and carbon emissions of the meat industry using livestock and precious farmland.

Since Novameat unveiled the world’s first 3D printed steak in 2018, the world has looked to 3D printing as a viable substitute for meat products using mainly plant-based ingredients satisfying to meat lovers, vegetarians and vegans, and environmentally conscious consumers alike.

With meat-free products being an $18.27 billion global industry, and traditional ranching taking up 35% of the world’s inhabitable land while the food industry as a whole is responsible for over 25% of total carbon emissions, meat is a priority for researchers and food companies from both a financial and ethical standpoint.

Here we’ll look at some of the most exciting and unique examples of 3D printed meat, from university research to seafood, and why the future of food is looking very bright.

- The Most Exciting 3D Printed Meat Projects

- Novameat – The World’s First 3D Printed Steak

- Redefine Meat – Cultured Meat Recreated With Care

- Aleph Farms – 3D Printing Meat in Space

- Steakholder Foods – Slaughter-Free 3D Printed Cultured Meat

- Osaka University’s Wagyu Beef – Bioprinting a Cultured Meat Substitute

- Shiok Meats – 3D Printed Seafood

- Pohang University – Algae: The Food of the Future

- Good Food Institute Reports – Bioprinting Meat Scaffolding

- VGN Boulevard – England’s Own Plant-Based Junk Food

- 3D Printed Meat Pros and Cons

- How Does 3D Printed Meat Work and What is it Made From?

- 3D Printed Meat- The History and the Science

The Most Exciting 3D Printed Meat Projects

Novameat – The World’s First 3D Printed Steak

- Price: N/A

- Learn More: Novameat

Novameat was the first company in the world to 3D print a meat-free beef steak in 2018. The Barcelona-based production group benefited from the founder and CEO Giuseppe Scionti’s decade of tissue engineering experience and expertise with lab grown meat.

The idea for 3D printing a steak came from the need for plant-based meat products that can emulate the actual texture and taste of real meat.

Targeting EU and UK markets initially, Novameat plans to offer its product in supermarkets and restaurants within five years.

Redefine Meat – Cultured Meat Recreated With Care

- Price: Variable

- Learn More: Redefine Meat

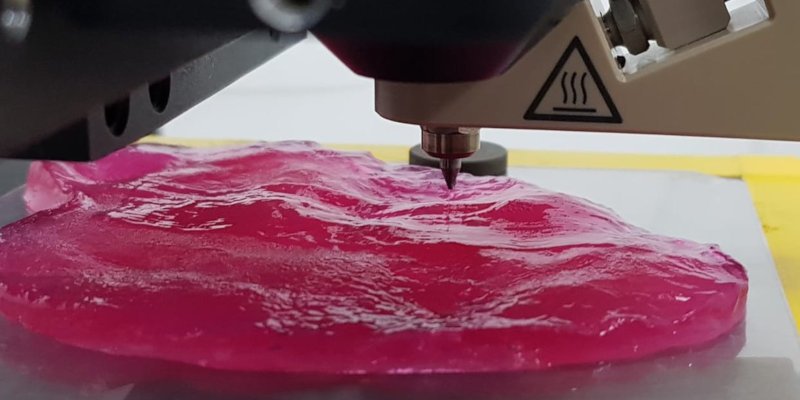

Redefine Meat collaborates with scientists and chefs to enhance 3D printed meat’s flavor. Their product mimics real meat in terms of taste, texture, color, and smell, using materials transformed into purees and 3D printed in layers.

Blood, fat and muscle cells are all recreated using a blend of natural colors and flavorings like coconut fat, legumes, and soy to emulate the texture of real meat without actually using any animal-based products. It’s not only steak on the menu either, as Redefine Meat also offers lamb and pulled pork substitutes in their online store.

Riding on a wave of positive reviews, Redefine Meat, much like Novameat, plans to launch its product globally in the near future and has already distributed its products to restaurants in Israel and Europe.

Aleph Farms – 3D Printing Meat in Space

- Price: N/A

- Learn More: Aleph Farms

Aleph Farms is another Israeli start-up that stands out by cultivating real meat from animal tissue samples. A small biopsy from an animal is developed in a nutrient-rich broth, promoting cellular division and organic growth.

In 2019, the company joined forces with Russia’s space program, Roscosmos, to test their meat samples in zero gravity at the International Space Station (ISS). The astronauts used a 3D printer to replicate the cells, effectively printing meat in space.

This meat wasn’t consumed in space, and was instead returned to Earth as a proof-of-concept to demonstrate limitless possibilities of this technology.

Steakholder Foods – Slaughter-Free 3D Printed Cultured Meat

- Price: Varies

- Learn More: Steakholder Foods

Steakholder foods is a 3D printed meat specialist company working for the future of foods. They use 3D simulations to customize your steak to your preferences, even down to fat content, while keeping it 100% ethical.

Using bovine stem cells cultivated for slaughter, Steakholder Foods also aims to reduce the environmental impact of the food industry. They also want to share their revelations to increase awareness of the decreasing necessity for livestock rearing and slaughterhouses.

Despite their name, they’re also developing alternatives to chicken and seafood to help reduce the carbon emissions and reliance on the fishing and fowl-rearing industries too. Their made-to-order steaks also help cut down on food waste by ensuring their products are only made when requested.

Osaka University’s Wagyu Beef – Bioprinting a Cultured Meat Substitute

- Price: N/A

- Learn More: Osaka University Research

Finding substitutes to standard meat products is an ongoing endeavor. Wagyu beef, a Japanese delicacy, is known for its marbling and disincentive savory flavor, so researchers at Osaka University tried to recreate it with 3D printing.

In 2021, the research team succeeded in 3D printing this new meat product that mimics the aesthetics and taste of the real thing right down to the texture of the muscle and fat tissue. Using lab grown animal cells, they were even able to recreate the blood vessels, fat cells, and muscle fibers that add to the mouth feel without hurting any animals in the process.

Shiok Meats – 3D Printed Seafood

- Price: $50+

- Learn More: Shiok Meats

Shiok Meats uses cell-based bioinks to recreate crustacean and shellfish meat using 3D printing. With the declining oceanic populations, the fishing industry needs to turn to more sustainable methods to keep our oceans as full of fish as our bellies are without sacrificing nutritional value. Shiok Meats seeks to make 3D printed fish and other seafoods more mainstream beginning with their flagship restaurant in Singapore.

Using these bio inks, Shiok Meats also combats food waste as the products they produce have a much longer shelf life than traditionally sourced fish, which takes only 1-4 days to become inedible. This environmental consciousness not only helps create and utilize sustainable solutions to overfishing, but is also a completely ethical alternative to contemporary seafood.

Pohang University – Algae: The Food of the Future

- Price: N/A

- Learn More: Phys.org

Algae is a vegan food option that’s easy to grow, sustainable, and quite cheap. Using this, researchers at Pohang university have used algae cultivated with light to create 3D printed meat that’s both vegan and environmentally friendly.

After noting the viability of 3D printed organs, the researchers were able to apply these bioprinting methods to create meat substitutes you can eat while maintaining the nutritional value of standard vegan foods.

Project leader Hyung Joon Cha has commented on their success in recreating functioning and stable cell structures and meat tissue with 3D printing helping both the food and medical industries.

Good Food Institute Reports – Bioprinting Meat Scaffolding

- Price: N/A

- Learn More: Good Food Institute

Dr. Sara Oliveira of the International Iberian Nanotechnology Laboratory in Portugal has used her experience cultivating stem cells to help the meat industry to create cultivated meat products sustainably by using bio ink for food 3D printing.

While her work mainly involves protein structuring, her research through the years 2020 – 2021 proved invaluable to the industry as a whole. This only adds to her over 4 years of experience as a researcher in 3D printed foods and cultivated meat.

VGN Boulevard – England’s Own Plant-Based Junk Food

- Price: £24.95 – £34.95 ($32 – $45)

- Learn More: VGN Boulevard

VGN Boulevard is a plant-based junk food restaurant in Stourbridge England. Their menu is entirely vegan and includes a special 3D printed sirloin steak made with a combination of coconut fat, pea protein, beets, and chickpeas.

The price varies depending on what size you want, but it’s still a very reasonable cost considering the engineering that went into it to emulate the muscle and fat tissues of real meat. Their 3D printed steak uses modern techniques to mimic the real thing and the reviews really speak for themselves.

Unfortunately, VGN is one of a kind, so you will need to make a reservation well in advance and possibly travel quite a long way if you want to check it out for yourself.

3D Printed Meat Pros and Cons

3D Printed Meat Advantages

Potential for Cost-Effective Production

3D printed meat has become more affordable in the last three years as the technology continues to evolve. While still more expensive than traditional meat products, these substitute 3D printed foods are becoming more accessible as the industry grows.

Take RedefineMeat, for example, whose steaks cost between $26 – $40. This is significantly more expensive than the average restaurant-bought steak made with traditional meats which only cost an average of $10 – $12.

The potential for cheaper production comes from the reduced need for livestock rearing, which is an expensive and environmentally damaging process. The plant materials used in 3D printing meat are cheaper and more sustainable to produce, and these savings will pass to the consumer.

Sustainability and Ethical Consideration

3D printed meat leverages fewer resources, consuming less water, land, and energy, leading to reduced greenhouse gas emissions. It offers a sustainable and ethical solution, appealing to most vegetarians and vegans due to its slaughter-free production.

Extended Durability

3D printed meat, made of robust vegetable compounds, outlasts traditional meat, as does cultured meat. Reduced refrigeration demands mitigate food waste and contribute further to sustainability via longer shelf-lives.

Drawbacks of 3D Printed Meat

High Initial Costs

Adopting innovative technologies often comes with high initial costs, and 3D printed meat is no different. The current limited production scale inflates the price, making it less competitive with conventional meat sources. Despite the ethical appeal of its slaughter-free production process, the high cost provides a hurdle for many families trying to make ends meet.

Perception Hurdles

The fact that most 3D printed meat alternatives still use animal stem cells and can involve some form of animal testing, many vegans and vegetarians will still not consider it to be a justifiable option.

This issue primarily concerns perception and could change as more people experience and enjoy these products. While it may not entirely shift dietary needs and preferences, it can stimulate consumers’ imagination.

How Does 3D Printed Meat Work and What is it Made From?

3D printed meat is made from bio inks which work like standard 3D printer filaments made from edible materials. These bio-filaments are typically made with a combination of plant-based materials and lab grown cells used to replicate the blood, fat, and muscle tissues present in traditionally sourced meat products.

3D printing allows us to distribute these puree materials into steak and other meat-like structures, recreating meat without needing livestock or slaughterhouses, presenting a real meat substitute that’s entirely cruelty free and environmentally sound.

This technology and technique is growing to the point where 3D printed meat products will someday be readily available and affordable outside of the projects and companies we’ve discussed today.

3D Printed Meat- The History and the Science

The exact vegetarian and vegan population is hard to estimate, but we can assume 4 – 6% of the US population will consider themselves vegan in 2023. This increase from 1% in 2014 increased the demand for meat alternatives indistinguishable from the ‘real’ thing that are ethically justifiable even by the strictest of diners.

3D printing technology plays a crucial role here. It was first conceived for food production by Cornell University students in the mid-2000s, using Fab@Home, the first publicly accessible multi-material 3D printer.

From an initially limited scope, beginning with easily malleable foods like dough, sauce, and chocolate, 3D printed meat has taken off to the point where it is commercially available, albeit not widely yet.

The technology has evolved significantly since the first commercial chocolate 3D printer, in 2012, advancing to the first meat-free 3D printed beef steak in 2018 by Novameat.

In these five short years, we’ve seen massive improvements in 3D printed meat as a viable substitute for traditional ranching and farming techniques, keeping us fed while helping to sustain the environment.