Polycarbonate filament is an extremely high strength and temperature-resistant material commonly used in parts that need to survive tough conditions, and in a variety of engineering applications. The ability to shake off high temperatures is both a blessing and a curse – PC is a notoriously difficult 3D printer filament to print – but we’ll explain some best practices in this Polycarbonate 3D printing guide.

With a glass transition temperature of around 150°C, nothing in the FDM 3D printer materials range can compete with it. PLA starts to lose form at around 60C, PETG at around 80°C, and ABS at 105°C. For high-temperature applications, PC is in a league of its own.

Polycarbonate filaments are also sometimes reinforced with carbon fibers or glass fibers to add strength and other properties.

What is PC Filament?

Polycarbonate or PC is an extremely strong, lightweight and transparent thermoplastic. Marketed under the trade name Lexan, it is used to make products as varied as CDs and DVDs, bulletproof glass, riot gear, sunglass lenses, scuba masks, electronic display screens, phone and computer cases, and much more.

PC has a very high impact strength, far greater than glass and more than ten times that of an acrylic material like PMMA. At the same time, it has less than half the density of glass, but with comparably high level of transparency.

In fact, polycarbonate transmits visible light better than many kinds of glass. It is this relatively light weight and transparency, combined with incredible strength, which makes polycarbonate printing such an attractive material choice for a wide variety of commercial uses.

Or even, just miniature vases like this one that we 3D printed at the TCT Show using printed Polycarbonate Filament 1.75mm.

It’s transparent like glass, but has far greater impact resistance and tensile strength. Therefore, Polycarbonate is perfect for transparent prints that will look great and mimic that glassy finish, and that are also tough as nails.

PC filament is also bendable – and machine bendable at room temperature – with this flexibility allowing it to withstand high tensile forces that break or shatter filaments like ABS.

It’s far tougher than filaments like ABS or PLA, and stands up very well to general wear and tear over time.

Aesthetics

Its high impact resistance ensures that it can stand up to a variety of demanding applications. It also has a relatively high heat resistance and can be bent at room temperature without cracking or breaking.

Other transparent thermoplastics, like PMMA, have a lower impact resistance and will crack and break if bent. This makes polycarbonate 3D printing an excellent choice for making functioning prototypes, especially where transparency and non-conductivity are desired.

In addition, PC can stand up to wear and tear. It is not delicate and won’t deform or break when handled. Finally, its clarity and ability to transmit light means that polycarbonate printing material will produce beautiful printed objects when used correctly.

Polycarbonate Filament 3D Print Settings

Ideally, you’ll want a hot-end that can reach at least 300°C, and a good heated bed. PC needs a high printing temp, but don’t worry – sometimes you can get away with just a 290°C hot end if you print slower. It has a wider melting range than other filaments.

We’ve taken a look at some of the benefits of using polycarbonate printing filament, now let’s take a look at its features:

- Strong and impact resistant

- Machine bendable at room temperature

- Extremely durable

- Transparent with excellent light transmittance

- Dichloromethane soluble

- Printing temperature from 300°C

- Recommended printing bed temperature of 110°C or higher

A look at the data stats of polycarbonate confirms the impressive strength of polycarbonate 3D printer filament. PC has a specific gravity of 1.18 g/cm³. This density makes it comparable to PMMA and PLA and about one-fifth denser than ABS. It has a Rockwell hardness of R 121, making it harder than PMMA, ABS and PLA.

Polycarbonate 3D Printing Best Practices & How To Print At Lower Temperatures

First of all, polycarbonate is heat resistant up to 116°C. It also has a glass transition temperature of 150°C. Therefore, polycarbonate filament settings are a higher printing temperature, the closer to 300°C the better.

If your extruder has a problem with temperatures this high, don’t worry. Polycarbonate has a relatively slow transition temperature. This means that it will successfully print at a lower than optimal temperature, albeit more slowly. This brings us to our second “How to 3D print with polycarbonate” tip.

In general, the lower your printing temperature, the slower your printing speed should be. We’ve found that 30mm/sec while using a polycarbonate filament temperature of at least 265°C will produce good results.

If you can get a higher temperature out of your extruder, you can experiment with a faster printing speed, say 60mm/sec. However, at the end of the day, slow and steady wins this particular race.

You also want to keep the temperature of your printing bed at 90°C or higher to avoid warping of the polycarbonate printing material. A higher printing bed temperature will also help to eliminate any delaminating issues that might arise.

When printing, keep in mind that polycarbonate 3D filament is extremely hygroscopic. This means it will absorb moisture from the air. The more water there is in the air, the more moisture the polycarbonate will absorb.

Polycarbonate that has been exposed to humidity will exhibit problems when being extruded, mainly bubbles and inconsistent flow that will tend to ruin your design. Storing your filament in an airtight container will minimize these problems.

Yet, as we’ve been discussing, it’s the category of overall strength that sets polycarbonate 3D filament apart from other thermoplastics. It has a maximum tensile strength of 11,200 psi (77.22 M/pa) which is comparable to PMMA.

However, it has a tensile break strength between 75% and 150%. Compare this to the tensile break strength of PMMA (1.8% – 7.2%), PLA (1% – 12%) and ABS (4.6% to 27%). What this means is that while both polycarbonate and PMMA are strong and hard, the ability of polycarbonate to withstand torsional stress far exceeds any other thermoplastic.

So, with polycarbonate you get a strong and durable material that can carry weight and survive rough handling, but is also flexible enough to withstand tensile forces that shatter, deform or break other materials. It also transmits light better than most types of glass.

So, if you’re looking for a strong, tough and flexible 3d printing material that’s also transparent, you need to give polycarbonate printing filament a spin.

Hot ends for 3D printing Polycarbonate

You will need an all-metal hot end for consistent Polycarbonate 3D printing, as PEEK or other material hot ends will struggle to maintain these high temperatures consistently. We recommend hot ends in our 3D printer hot end buyer’s guide.

Heated bed temperature

You will also need a heated bed, heated up to at least 90°C, and preferably higher at 120°C+, and commonly even 135-150°C. Most 3D printers cannot handle these temperatures, but if you try the highest temperature your 3D printer can maintain, you may still be able to 3D print PC filament without too much warping.

Enclosure for 3D printing Polycarbonate

You will also need a 3D printer enclosure to keep the heat in around your 3D printer. If your 3D printer doesn’t come with an enclosure, you can buy one, or build one yourself. It just needs to keep heat in effectively to reduce warping and layer splitting.

There a number of good 3D printer enclosures we recommend below:

Best Polycarbonate Filament

Below are links to some of the Polycarbonate filaments we recommend for 3D printing. We have included links to lower cost PC filaments, as well as glass-filled and carbon-filled filled filaments for those interested in hybrid filament mixes.

- Our full list of Polycarbonate filament recommendations

- Polymaker PC and PLA combined filament range

- Glass-filled PC filament recommendation

- 3DXTECH Carbon-fiber filled PC filament

Best Polycarbonate 3D Printers

| Name and brand | Build volume | Price | Best place to buy | Alternative purchase option |

|---|---|---|---|---|

| Pulse XE | 250 x 220 x 215 | $999 | Matterhackers here | |

| Qidi Tech X-Max | 300 x 250 x 300 | $1,099 | Amazon here | |

| Ultimaker S3 | 230 x 190 x 200 | $3,850 | Dynamism Store here | Matterhackers here |

Polycarbonate 3D printing guide and tips

Warping: Polycarbonate warps a lot – even more than ABS – and layers often split if you 3D print polycarbonate under the wrong conditions. The key to minimizing warping is a high-temperature heated bed, effective heated chamber or enclosure to keep heat in, and good layer adhesion. You also need to make sure your 3D printer is calibrated perfectly, as too far or close Z-offset distances will worsen warping and ruin your prints.

To insert the table into a page, post, or text widget, copy the Shortcode and paste it into the editor.

Fumes and odors: like ABS, Polycarbonate (PC) filament also produces fumes and odors. Make sure you print in an area with good ventilation, and try not to be in the same room while printing.

Build surface: Polycarbonate is very temperamental, and struggles to stick to anything except itself. Therefore, a good option for 3D printing Polycarbonate is to use a Polycarbonate cutting board, and then use an adhesive such as glue stick or hairspray on this cutting board to improve layer adhesion. PEI sheets can also work, though different people give different reviews, but other build surfaces such as blue painter’s tape will lose their ability to stick at such high temperatures. Some report that just very strong glue can work, such as on glass surfaces, but this can cause the print to stick far too well to the build surface, causing damage to the glass surface when removing the print.

Fix retraction settings: This will minimize oozing. Avoid large (10mm+) retraction distances.

Consider using a larger nozzle: Though this is a trade-off between surface finish and layer adhesion. Using a larger 3D printer nozzle will improve layer adhesion if this is something you are struggling with, as the larger surface area improves the bonds between layers. However, this comes at the cost of some surface quality finish. We recommend nozzles that are better equipped to handle tough filaments such as PC in our 3D printer nozzle guide.

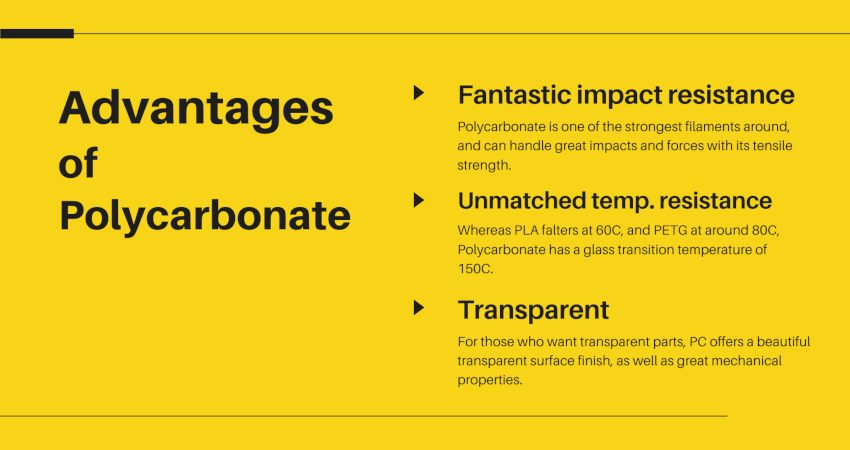

Advantages of Polycarbonate 3D printing

- Fantastic impact resistance: Polycarbonate is one of the strongest 3D printer filaments around, and can withstand huge forces and boasts high tensile strength.

- Unmatched temperature resistance: For parts that need to be able to handle very high temperature, Polycarbonate offers the best temperature resistance around.

- Transparent surface finish: The best option for high quality, transparent parts. Though PETG is also transparent, PC filament has better impact resistance and temperature resistance.

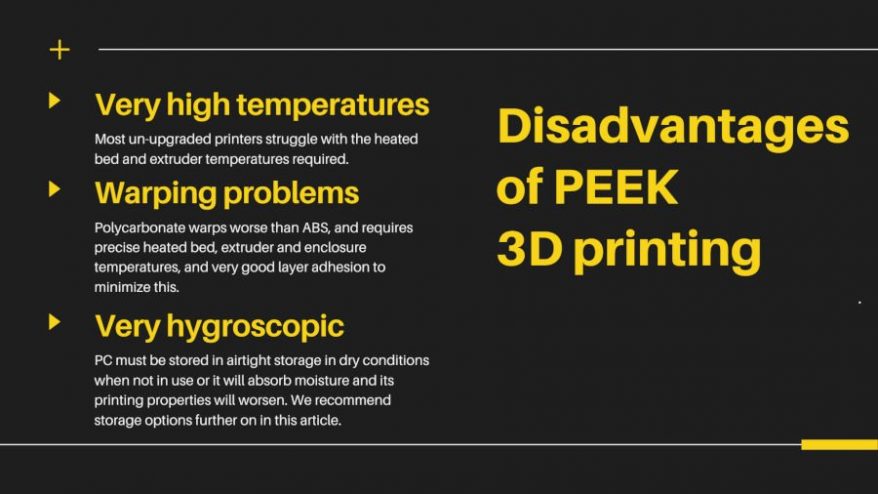

Disadvantages of PCfilament

- Very high temperatures required to print: Some 3D printers cannot match the temperatures required, and most stock 3D printers cannot go above 300°C. Most will also struggle to maintain the heated bed temperatures required. You also require an all-metal hot end to effectively 3D print Polycarbonate.

- Problems with warping: PC warps even more than ABS, and requires very precise printing settings to avoid this.

- Very hygroscopic: Polycarbonate absorbs a lot of moisture from the air if left out in the open, which can quickly cause the material to swell, and worsen 3D printing characteristics. It must be kept in airtight, dry conditions at all times when not 3D printing Polycarbonate.

- Very sensitive to UV rays and hydrolysis: Unsuitable for any outdoors use, as Polycarbonate with degrade in the sun, and reacts poorly to water.

PC Applications

Polycarbonate, outside of 3D printing, is commonly used in applications that benefit from its transparency, such as optical glass, and bulletproof glass due to its phenomenal impact resistance. It is also used in electrical and phone casings, bike and motorbike helmets, and other strong parts like scuba diving masks and even riot shields.

Within 3D printing, PC is commonly used in engineering applications where high strength and flexibility is key. Some rely on PC for remote-controlled 3D printed car parts, and general projects that need to handle higher temperatures and strong impacts.

How to Store PC filament

Polycarbonate is extremely hygroscopic, and should only be stored in dry conditions in airtight storage or it will swell and its 3D printing properties will worsen.

We recommend the following containers:

Related articles: