Nylon filament is one of the toughest and best-looking filaments around – you can create impact-resistant parts that look great, yet for notably cheaper than filaments like Polycarbonate.

Unfortunately, unlike filaments like PLA, your average desktop printer will struggle with the high temperatures Nylon needs to print properly, as well as the carefully managed cooling via an enclosure to prevent it from warping.

You also need to take good care of your Nylon filament – it is very hygroscopic.

So we’ve picked out the best 3D printers for nylon that can handle the temperatures – starting at the lowest price range.

It is worth noting that while all of these Nylon 3D printers are good for Nylon printing, even tougher and more abrasive filament blends – like carbon fiber, kevlar or glass mixes – require extra consideration.

Standard brass nozzles will be destroyed quickly – you’ll need hardened steel or ruby – and not all printers are designed for this. The Pulse XE is designed especially for abrasives, however.

Best Nylon 3D Printers 2023 – Reviews

1. Qidi Tech X-Plus – Best Low-cost Enclosed 3D Printer for Nylon

- Price: Check price on Amazon here

- Build volume: 270 x 200 x 200 mm

Pros

Versatile thanks to dual interchangeable extruders.

Ideal for PLA, ABS, TPU, and PETG projects.

Comes with an enclosed chamber and air filtration system.

Cons

Price may be too high for beginners.

An excellent offering from Qidi Technology, our breakdown of the best printers for nylon wouldn’t be complete without mentioning the Qidi Tech X-Plus.

Versatility acts as a cornerstone of what the Qidi Tech X-Plus is all about, chiefly thanks to dual interchangeable extruders.

The basic extruder hit temperatures up to 260°C, ideal for your PLA, ABS, TPU, and PETG projects. But for nylon printing, the other cranks up the heat to 300°C.

This duality also extends to the double-sided print bed with different adhesive qualities on each surface. One side is designed for your standard filaments; flip it over to use temperature-sensitive materials like nylon.

Another central selling point is the Qidi Tech X-Plus’ enclosed chamber and air filtration system, which go the extra mile compared to other similar nylon-capable 3D printers. The chamber helps reduce printing errors by maintaining a stable thermal environment, vital when working with nylon and ABS.

Added niceties such as Wi-Fi connectivity, a touch screen, print resume, and dual filament holders bolster the Qidi Tech X-Plus feature list beautifully. You’ll also find a 270 x 200 x 200 mm build volume; not the largest out there, but certainly enough for medium-sized functional parts.

On the whole, we’d say the Qidi Tech X-Plus provides an excellent solution for semi-professionals in the market for a versatile nylon-capable printer. It’s affordable and has features generally reserved for the price rung above.

2. Prusa i3 MK3S+

- Price: Check latest price at Prusa store here / Amazon here

- Build volume: 250 x 250 x 210 mm

Pros

Reliable and durable, like all Prusa printers.

Fast speeds of up to 200m/s.

Custom E3D V6 hot end to do the heavy lifting.

Cons

Small print area.

Straight from the folks with arguably the best reputation in the 3D printing game, we have the Prusa i3 MK3S+, one of the best all-around 3D printers on the market today.

While you’ll usually find owners praising it for PLA, PETG, and flexibles, the Prusa i3 MK3S+ impresses as much with more exotic, demanding filament types, including nylon.

A custom E3D V6 hot end does the heavy lifting in that sense. Sporting overall high-quality all-metal components, the hot end can comfortably reach a peak temperature of 300°C.

Alongside the hot end, you’ll find a Prusa’s own MK52″ heat bed, capable of hitting 120°C, perfect for nailing a warp-free first layer of temperature-sensitive material. Nylon is a heat fiend, and the Prusa i3 MK3S+ dishes out all the toasty, thermal goodness needed to shine.

Discounting errors on the user’s part – the most common culprit for failed prints – the Prusa i3 MK3S+ generates admirable nylon results. It’s easy to forget this is an FDM printer by the level of detail on offer here. As it’s nylon, the parts retain all the durability and abrasion-resistance you’d expect, making them suitable for functional parts like hinges and gears, for example.

Nylon performance aside, the Prusa i3 MK3S+ has a feature list worth flaunting. Highlights include easy SuperPINDA 2 automatic mesh bed leveling, a filament sensor, power loss recovery, and ‘Stealth Mode’ near-silent printing. We’re merely scratching the surface here of what is a sophisticated, highly-reliable prosumer machine.

With the Prusa MK3S+ soaking in a glut of positives, it’s hard not to recommend it as one of the best 3D printers for nylon, whether you’re a beginner or a seasoned maker.

However, it is an open-air 3D printer by default – options for enclosing it include buying the official Prusa enclosure, or making your own enclosure from scratch.

3. Pulse XE

- Price: $999 — Available at Matterhackers here

- Build volume: 250 x 220 x 215 mm

Pros

Capable of delivering precise printed parts.

Thick aluminum frame and does not vibrate.

Cons

The build volume is small for the price.

The Pulse XE is a robust, machined aluminum 3D printing brute designed from the ground up to handle the most exacting, abrasive, and challenging material types under the sun, including nylon.

This is a machine to make durable parts for demanding real-world applications. Despite its tank-like build, the Pulse XE is a gentle giant of sorts – incredibly easy to set up and use from the get-go.

The Pulse XE houses the same best-in-class E3D V6 hot end as the Prusa i3 MK3S+ (it’s based on the Prusa design). Quickly hitting a maximum temperature of 300°C, the hot end has some help carrying nylon to great prints results from a heated bed with a LayerLock Garolite surface and Bondtech BMG extruder.

In action, the Pulse XE offers Prusa-level reliability with few noticeable imperfections and a superb finish on printed parts, making it one of the top nylon-capable 3D printers on the market.

Other positives include an automatic BLTouch bed leveling probe, filament run-out sensor, power resume function, and a respectable 250 x 220 x 215 mm build volume.

Put simply; the Pulse XE gathers up all the dream modifications you could think of and houses them in one sturdy piece of 3D printing kit. It’s a workhorse that performs out of the box. If demanding materials like nylon feature on your 3D printing bucket list, but you still want a printer equally at home with staples like PLA and Flexibles, consider the Pulse XE.

4. Dremel 3D45

- Price: Check price on Amazon here / Available on Matterhackers here / Available on Dynamism here

- Build volume: 255 x 155 x 170 mm

Pros

Minimal setup and easy-to-use features.

Ships with great learning resources.

Cons

Lack of experimentation possibilities.

Power tool manufacturer Dremel’s move to 3D printing has been something of a hit thanks to the Dremel 3D45. A fully-enclosed ecosystem printer aimed at schools, the Dremel 3D45 eases that steep 3D printing learning curve. Best of all, it works beautifully with nylon, and simplifies those first experimental prints.

Safe and dependable, thanks to carbon filters and transparent covers, the Dremel 3D45 melds into any learning environment. But, it still packs great printing capabilities under the hood.

A 255 x 155 x 170 mm build volume gives you enough room for small to medium-sized parts for, say, automotive or low-level robotic parts. You’ll also find other noteworthy features. These include a filament sensor, semi-automatic bed leveling, free lesson plans, and great slicing tools.

As for the Dremel 3D45 nylon printing, you can expect strong, durable prints with the right amount of flexibility for thinner parts. Dremel’s all-metal hot end can reach 280°C and the 100°C heated bed maintains suitable adhesion levels for consistent results.

While the Dremel 3D45’s great, there is one major concern. The printer only performs at its best when using Dremel’s proprietary filament. This is by design for an ecosystem printer for day-in, day-out educational use. You can, of course, use third-party filament. But, expect to fine-tune temperature settings to hone in on the best print quality.

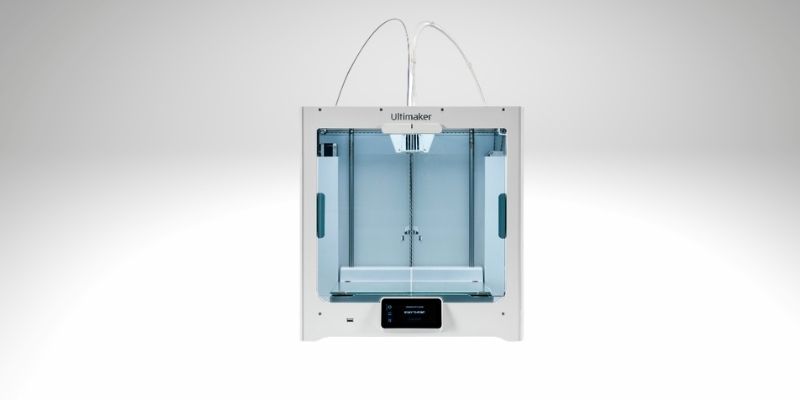

5. Ultimaker S3

- Price: ~$4,000 — Available at Matterhackers here / Available at Dynamism here

- Build volume: 215 x 215 x 200 mm

Pros

Fantastic precision of 20-micron minimum layer height.

IDEX dual extruder allows you to print two materials in one job.

Cons

Price and lack of speed make it best for low-volume prototyping.

Following in the footsteps of the critically acclaimed Ultimaker 3, which burst onto the 3D printing scene back in 2017, the Ultimaker S3 is a powerful dual extrusion 3D printer suitable for professional and design applications.

The dual extruder setup oozes versatility, extending its competence to everything from ABS and PLA to PVA, CPE, and nylon. Whatever you throw at the Ultimaker S3, the print results are nothing short of excellent, with a particular emphasis on clean edges and smooth finish when printing with nylon. For those functional applications where durability and dependability are essential, the Ultimaker 3 absolutely sings.

Peeking briefly at the specifications list, the Ultimaker 3 hits its stride there, too. A decent 215 x 215 x 200 mm build volume, swappable print cores for different filament types, an enclosed chamber, Wi-Fi connectivity, automatic bed leveling, a layer resolution up to 20 microns, and a heated glass bed.

The only issue holding back the Ultimaker S3 is lengthy print times. Blame the fact we’ve become accustomed to much speedier printers due to advances in the intervening years. Key in fine-detail prints, especially when using several material types, and you’re in for a long old slog numbered in the dozens of hours.

6. Ultimaker S5

- Price: $6,300 — Available at Matterhackers here / Available at Dynamism here

- Build volume: 330 x 240 x 300 mm

Pros

Excellent precision and accuracy.

Fits well into a commercial workflow.

Comes with automatic bed leveling, an enclosed chamber, and the same dual extrusion capabilities as Ultimaker s3.

Cons

There are a few larger options available for less money.

The Ultimaker S5 is a professional-grade printer fit for all manner of applications. Much of this is down to how it tackles various filament types, including nylon, all in a streamlined, functional setup that delivers outstanding print quality.

You certainly pay for the pleasure, and the Ultimaker S5 prices out hobbyist makers, who’d be better served with the more affordable, if older, Ultimaker S3. That said, for business and expert makers with the budget to spare, the Ultimaker S5’s price tag is entirely justified.

Beyond extensive material compatibility, the Ultimaker S5 ships with a large-scale 330 x 240 x 300 mm fit for series batch-printing, large prototyping, functional parts, and everything in between.

Add in automatic bed leveling, an enclosed chamber, the same impressive dual extrusion capabilities Ultimaker S3, a touchscreen, and a heated bed. List the most coveted features among designers and engineers, the Ultimaker S5 has them.

While we could happily keep praising this machine to stress just how impressive an offering we have here, the Ultimaker S5 is best considered a super-sized, souped Ultimaker S3, itself one of the best affordable nylon printers around.

Buyer’s Guide – What To Look Out For In a Nylon 3D Printer

Here are a few key features to look out for when shopping around for a nylon 3D printer:

All-Metal Hot End

Nylon requires high temperatures. A hot end capable of safely and consistently reaching 300°C is recommended as this covers the full run of filament manufacturer recommendations.

Another concern of non-all-metal hot ends is the internal PTFE tubing, which can break down and release toxic fumes at around 240°C. Given that 240°C sits at the lower end of nylon’s usual temperature requirements, you’ll likely push past it on a regular basis.

Enclosure

Much like ABS, nylon is particularly susceptible to changes in ambient temperature. Temperature drops cause curling and other deformations that ruin prints.

Though not 100% necessary, a printer with an enclosure drastically decreases the likelihood of these types of issues ruining your nylon printing experience.

There’s also particulate dust to consider when printing with carbon fiber and other composite nylon. A printer with a HEPA air filter is highly recommended.

Heated Bed

A heated bed will help with first-layer adhesion and help prevent warping. Allied to an enclosure, a heated bed provides all the heat nylon requires to produce quality, warp-free prints.

Bed Leveling

Though not required, automatic bed leveling will vastly improve your time with a printer. It removes the hassle of manual leveling, allowing you to print faster and more efficiently.

Nylon 3D Printer Tips and Tricks

Nylon 3D Printing Settings

- Nozzle Temperature: 230°C to 290°C

- Heated Bed Temperature: 25°C to 80°C

- Hotend: All-metal capable of reaching 300°C

- Print Speed: 30 mm/s to 60 mm/s

- Layer height: 0.2-0.4 mm

- Fan speed: 0%

- Bed Surface: Glass, garolite

- Adhesion: Magigoo, PVA glue

- Enclosure: Highly recommended but not required

Storing and Drying Nylon

Though nylon has many excellent properties, a major downside is that it easily absorbs moisture from the air. It does this at such a rapid rate that leaving Nylon filament out for just a few hours can degrade it to the point that it ruins parts and sours nylon’s signature smooth surface finish.

To avoid moisture-related issues, it’s essential to store nylon correctly. Typical solutions include sealed air-tight containers and resealable vacuum bags with desiccant sacs. Should the nylon absorb moisture, the issue isn’t permanent as it’s possible to dry the filament ready for 3D printing.

Here you have options. One of the most common is to place the filament in a domestic oven at roughly 70-80°C for around six hours. Doing so extracts all the moisture.

Alternatively, you can invest in a purpose-built filament dryer like the PrintDry Pro or Sunlu FilaDryer S1. The latter goes a step further as it allows you to print alongside drying the filament, perfect if you’re working in humid conditions where leaving the nylon exposed to air is problematic.

Bed Adhesion

Aside from being hygroscopic, one of the biggest challenges with printing nylon is just how prone the material is to warping. It doesn’t take much for nylon to throw a tantrum and cough up adhesion problems.

To give yourself a fighting chance, you’ll want to tune the nozzle and heated bed temperatures correctly, but also use a bit of extra adhesive to help to ensure a solid first layer.

Applying a layer of inexpensive, readily-available PVA-based glue onto the bed before printing works well, as do more specialized alternatives like Magigoo or Kapton tape. We recommend bed surfaces here.

Beyond adhesives, we recommend brims and rafts for every print. These act as an extra buffer to ensure the part sticks and is held down well to the bed and doesn’t warp. They mean using a bit more filament with every print, but the benefits far outweigh the extra material spent.

Pay Attention to Manufacturer Recommended Settings

Due to different blends, composite fills, raw material quality, and manufacturing processes, not all nylon brands have the same printer setting requirements. Pay attention to what the filament manufacturer recommends, especially in terms of the nozzle and heated bed temperature.

You’ll often find manufacturers unhelpfully listing temperature ranges rather than a specific number. While troublesome, this is to cater to as many printers as possible. Start from the highest recommended temperature and work your way down. Alternatively, a temperature tower test should help you zero in on the optimum settings.

Fans Off

Turn the part cooling fan off on your printer when working with the nylon. The material is extremely sensitive to temperature changes, and introducing rapid cooling can exacerbate first layer adhesion issues and warping.

Nylon prefers to cool at its own pace. Controlled and uniform cooling avoids warping and ensures parts come out with a smooth finish.

Print Slow

Another major point from the best practice nylon playbook is to print slower than you would with ABS or PLA. Around 30 to 50 mm/s is ideal, but never beyond 60 mm/s.

The optimum setting depends on your specific printer and filament brand, so be sure to dial in the print speed with a few initial test prints to see what works best.

Advantages and Disadvantages of Nylon

Advantages

- Strong and durable – Nylon boasts a high tensile strength and is extremely durable even under strain.

- Impact-resistant – Nylon can sustain heavy forces for long periods of time without degrading or breaking.

- Abrasion-resistant – Nylon weathers friction well, making it particularly suitable for applications such as functional gears and living hinges.

- Flexible – Though not as flexible as filaments like TPU, nylon is far more flexible than ABS and PLA. Additionally, it’s particularly useful for thin prints that require strength alongside flexibility.

Disadvantages

- Extremely hygroscopic – If left exposed, nylon absorbs water. Though this isn’t particularly an issue for printed parts, it’s a problem for spooled filament. When wet it can cause all manner of printing issues as it feeds through the hot end where the water effectively boils, degrading the filament and causing clogs.

- Prone to warping – Due to the fact it’s highly heat-sensitive, nylon is susceptible to warping, making it one of the more challenging materials to 3D print.

- Requires correct storage – To avoid moisture issues, nylon needs to be stored correctly, which can add extra cost.

Nylon 3D Printer Applications

- Manufacturing, industrial, and engineering – interlocking gears, machine parts, tools, bolts, nuts, hinges, cable ties.

- Design – rapid prototyping.

- Electronics – housing and insulation.

- Hobbies – drone chassis, RC car parts, tyres, wheels.

Can Any 3D Printer Print Nylon?

No, not all 3D printers can print nylon. Nylon properties make it particularly challenging to print, and many low-cost printers, generally designed to print PLA and ABS, simply won’t be able to keep up.

How to Dye 3D Printed Nylon?

Thanks to its hygroscopic properties, nylon is well suited to dyeing. MatterHackers offers an in-depth guide to dyeing nylon, either before or after printing.

How Strong Is 3D Printed Nylon?

When 3D printed, nylon exhibits a 7,000 psi tensile strength, allowing it to sustain forces up to 200 kg before any sign of degradation. Nylon is strong, durable, and particularly resistant to impact, wear and tear, sustained friction, and abrasion.

FAQs

What 3D Printers Can Print Nylon?

To print nylon, you’ll need a printer with an all-metal hot end capable of reaching temperatures up to 300°C, an enclosure, and, if you’re printing with composite filled nylon, a hardened nozzle. The Qidi Tech X-Plus, Prusa i3 MK3S+, Pulse XE, Dremel 3D45, and Ultimaker S5 are solid choices for 3D printing nylon.

What Is the Best 3D Printer for ABS and Nylon

One of the main crossovers between ABS and nylon is that both materials require a stable thermal environment to curb issues like warping. A printer with an enclosure will keep the printer operating in a steady and constant environment. Printers like the Qidi Tech X-Plus and Ultimaker S5 have a fully-enclosed chamber making them suitable for tricky filaments like ABS and nylon.

Can Ender 3 3D Print Nylon?

No, the stock Ender 3 isn’t designed to handle nylon. However, with a few targeted upgrades, notably an all-metal hot end like an E3D V6 and an enclosure, and a firmware upgrade to raise the max temperature ceiling, the Ender 3 can handle nylon printing. You can read more in our Ender 3 filament guide.

Can You 3D Print Glass Filled Nylon?

Absolutely, though if you have a brass nozzle, you’ll need to swap it out for a more robust and durable alternative, such as a hardened steel nozzle, to print glass-filled nylon filament (NylonG).

Can You 3D Print Nylon Indoors?

Yes, but you’ll want to do so in a well-ventilated area as nylon is known to produce potentially toxic fumes and particulate dust, or alternatively, use a sealed enclosure with an air filter.

Do Nylon 3D Printed Parts Shrink?

No, nylon 3D printed parts aren’t known to shrink. On the contrary, 3D printed parts excel at retaining their shape and structure even under heavy loads and high temperatures if printed correctly.

How Much Does It Cost to 3D Print Nylon?

It varies. You need to factor in the cost of the printer (anywhere from $700.00 to $6,000) and the cost of filament (anywhere from $30.00 to $80.00 per spool). For the best results, you’ll also need some sort of storage solution and drying equipment, the latter costing anywhere from $50.00 to $200.00.

Is 3D Printing Nylon Safe?

Overall, and with the proper precautions, 3D printing nylon is safe. Ensure you work in a well-ventilated area and use a printer with an enclosure and air filtration system. As with all 3D printing, avoid touching the heated parts during operation.

Related articles:

- The best 3D printers for ABS

- Best 3D printers for PEEK

- Best 3D printers for carbon fiber

- Best metal 3D printers

- Best Nylon filament