Carbon fiber is strong, stiff, light, and increasingly affordable to 3D print for companies, engineers, and designers. Carbon fiber is an effective replacement for many metal parts in the industry, with 3D printing offering faster prototyping, functional testing, and end-user part carbon fiber production.

So, for any decision makers looking to implement carbon fiber 3D printing into their workflow, we’ve summarized all your carbon fiber 3D printer options under $10,000.

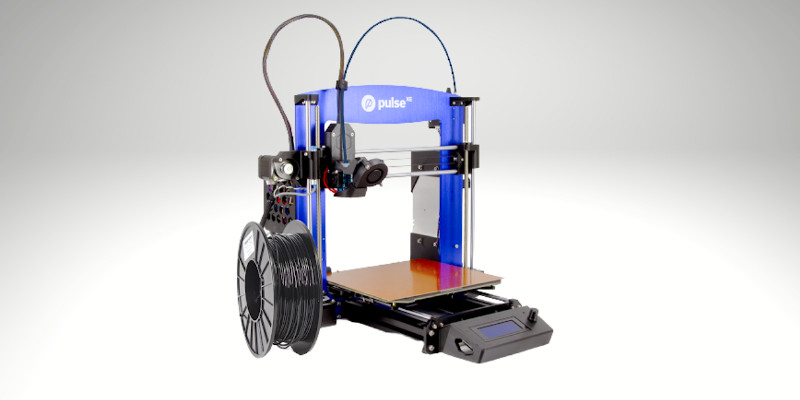

1. Pulse XE — Lowest Cost Carbon Fiber Printer

- Price: $999 — Available on Matterhackers here

- Build volume: 250 x 210 x 215 mm

Pros

Capable of delivering precise printed parts.

Thick aluminum plate and does not vibrate.

Cons

The build volume is small for the price.

Made by trusted 3D printer retailer Matterhackers and inspired from the original Prusa design, the Pulse XE is a low cost carbon fiber 3D printer especially designed to print Matterhackers’ NylonX filament.

NylonX is a mix of nylon with carbon fibers, with the Pulse XE able to print a range of other carbon fiber filaments thanks to its fitted Bondtech BMG extruder and E3D V6 hot end, along with your choice of either a hardened steel nozzle or ruby-tipped nozzle if you choose to upgrade. It’s marketed as a general advanced materials 3D printer capable of printing a variety of other tougher composite and abrasive filaments.

The Pulse XE offers a far cheaper way of 3D printing carbon fiber, but you’ll likely need the enclosure kit (another $300) to avoid warping as maintaining temperature is more difficult in an open air 3D printer than an enclosed 3D printer.

- We also have a ranking of the best enclosed 3D printers.

Taking after the Prusa, it’s a reliable workhorse 3D printer that can also print standard filaments like metal filled filaments, PETG, and many advanced and abrasive filaments and composites. It prints up to 60mm/s (but be wary with tougher materials and slow down if you face issues), with resolutions of up to 20 microns possible.

You can mix and match and upgrade as you see fit based on your needs and preferences, including a hi-res LCD screen, upgrading to a 32-bit board, ruby nozzle, and a host of other improvements — it’s a very versatile carbon 3D printer that’ll save you some money compared to other 3D printers for carbon fiber if you’re on a tight budget.

2. Raise3D E2

- Price: $3,499 — Available on Matterhackers here / Available on Dynamism here

- Build volume: 330 x 240 x 240 mm

Pros

Large building volume.

High-quality prototyping.

Dual extrusion printing capabilities.

Cons

Not a specialized carbon fiber 3D printer.

Raise3D make excellent professional 3D printers capable of large-scale 3D printing and high quality prototyping, and we could have also picked the Raise3D Pro2 Plus as an excellent carbon fiber 3D printer option for larger carbon fiber prototypes.

The Raise3D E2 is an enclosed 3D printer featuring IDEX technologies with Mirror and Duplication modes for efficient and effective dual extrusion 3D printing that still offers good print volumes. It’s fully enclosed, with a controlled heated chamber ideal for printing small to medium-sized carbon fiber prototypes.

- And if you’re looking to print larger (up to 600mm tall) prototypes instead, go for the Raise3D Pro2 Plus.

The Raise3D E2 comes with a host of features that make your workflow easier and more efficient, including filament run out sensors, print resume features in the event of a power loss, and a full-color touchscreen with all analytics viewable during printing. The printer also comes with a flexible build plate that makes removing parts easier without damaging them — ideal for quickly removing carbon fiber prototypes to test them and iterate.

The Raise3D E2 CF is also set for release soon, further adding to the carbon fiber printing potential the E2 offers.

It’s not a specialized carbon fiber 3D printer, but it can handle carbon fiber filaments without issue. Beyond just carbon fiber 3D printing, the E2 also comfortably prints glass fiber infused filaments, PP, PC, Nylon, metal filled filaments, ABS, and more.

3. Fusion3 F410 — For Large Carbon Fiber Prototypes

- Carbon fiber 3D printer price: $4,999

- Build volume: 355 x 355 x 315 mm

Pros

Fast print speeds of up to 250mm/s.

Excellent build volume.

Can add HEPA air filters to keep your print environment.

Cons

Some assembly is required.

Offering professional quality and industrial volume at desktop prices, the Fusion3 F410 is one of the top options around if you’re looking for a 3D printer for carbon fiber.

It’s fast — 250mm/s print speed — offers up to 20-micron layer resolution, and is ideal for both businesses and classrooms for 3D printing either larger prototypes or many smaller parts simultaneously for a class. You can add HEPA air filters to keep your print environment more pleasant and prevent any harmful gases being inhaled during the print process.

For 3D carbon fiber printing, the F410’s excellent build volume, large heated bed and enclosed print area make it ideal for high temperature filament printing. It’s been tried and tested with a number of different carbon fiber reinforced filaments, including 3DXTech and various other brands and composites, proving every time to work well. Almost all carbon fiber filaments should be compatible with it, owing to its 300°C maximum nozzle temperature — but you can read the full list of compatible filaments here.

The F410 comes with a hardened steel nozzle that can handle the abrasiveness of carbon fiber and other trickier filaments, and is an ideal carbon fiber 3D printer for under $5,000.

4. Makerbot Method and Method X Carbon Fiber Edition

- Price: $5,499 — Available on Matterhackers here / Available on Dynamism here

- Build volume: 190 x 190 x 196 mm

Pros

Print carbon fiber-reinforced Nylon or projects.

Easy to use.

Cons

Very expensive.

Makerbot’s specialized carbon fiber printer, the Method (and Method X) Carbon Fiber Edition, is designed to save businesses costs prototyping and creating, improve productivity, and encourage faster innovation.

The Method Carbon Fiber prints carbon fiber-reinforced Nylon as well as a host of other engineering-grade composite filaments. Makerbot themselves offer two carbon fiber Nylon blends:

- Nylon 6/66: offering fantastic strength to weight ratio and good heat resistance.

- Nylon 12: offering better moisture resistance, as well as a simpler and more reliable 3D printing experience overall.

Both Nylon carbon fiber 3D printer materials work well in structural applications and in general tough part production, with Makerbot championing the materials for replacing metal parts.

In addition to these carbon fiber nylon filaments, Makerbot offer SR-30 soluble filaments that can be dissolved for flawless surface finishes on parts, and a range of other high-quality materials. You can also use other materials as the Method is an open platform for other advanced filaments.

The Method features a 60°C heated chamber, and if you want to go higher, you can instead buy the Makerbot Method X which can reach 110°C to print a wider range of composite materials. You get a dual extruder for multi-material or multi-color 3D printing, and up to 20-micron resolution and 0.2mm dimensional accuracy.

Some may find the smaller than average build volume an issue, especially as if you are planning on using the dual extruder the X-axis maxes out at 152mm rather than 190mm. However, for small and medium part production the Method Carbon Fiber 3D printer is a great overall option, packed with features to maximize prototyping efficiency including a flexible steel build plate for adhesion and quick part removal, a 5-inch full color touchscreen for efficient printer interaction, and a camera for remote print monitoring.

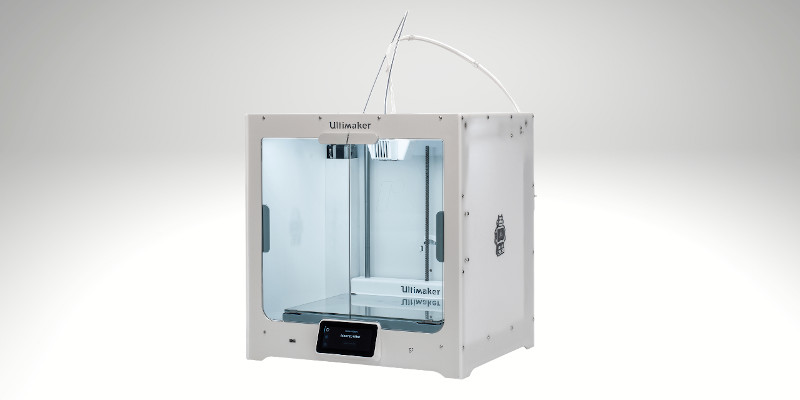

5. Ultimaker S5

- Price: $5,995 — Available on Matterhackers here / Available on Dynamism here

- Build volume: 330 x 240 x 300 mm

Pros

Excellent, best-in-class precision and accuracy.

Fits well into a commercial workflow.

Cons

There are far larger 3D printers available for less money.

A favorite among designers, prototypers and companies worldwide, the Ultimaker S5 marries fantastic precision and part quality, with the robustness and reliability of a top FDM 3D printer.

The S5 isn’t as standard a carbon fiber 3D printer, but can be upgraded by buying Ultimaker’s CC Red 0.6 print core, which seamlessly slips into place to start printing abrasive and advanced filaments like carbon fiber. The CC Red works on both the S3 and S5, but not for the Ultimaker 3.

The upgraded print core transforms the Ultimaker S5, giving you all the S5’s precision and reliability in creating fantastic prototypes, as well as the ability to print carbon fiber composites. You can print with dual extruders without issue, and the S5 comes with a 7-inch full color touchscreen for easy operation and print monitoring, and a removable glass print bed for good carbon fiber part adhesion and easy part removal.

6. XYZprinting PartPro300 XT

- Price: $5,500 — Available on Dynamism here

- Build volume: 295 x 300 x 300 mm

Pros

Advanced filament printing.

Fast printing speeds.

Regulated heating chamber and enclosure.

Cons

Cooling parts may be a problem for some because of the closed body.

XYZprinting have expanded far beyond their original horizons when they producing some of the best selling cheap 3D printers around — they now sell SLS 3D printers, a handheld 3D scanner, and full color 3D printers.

The PartPro300 XT is XYZprinting’s venture into making a commercial 3D printer capable of consistently printing advanced filaments like carbon fiber. Its dual extruders are fitted with hardened steel nozzles that can handle carbon fiber’s abrasiveness, and prints at a very fast 300mm/s for the rapid prototyping of large parts in record time.

Like most carbon fiber 3D printers the PartPro300 XT has a regulated heated chamber and enclosure for high quality part production, preventing temperature deviations that could cause imperfections in the prototype. The PartPro300’s filament humidity system prevents conditions from affecting filament quality, ensuring parts are as strong and offer the best surface area possible. Overall, it’s a powerful carbon fiber 3D printer that can print a range of other engineering-grade filaments too without issue.

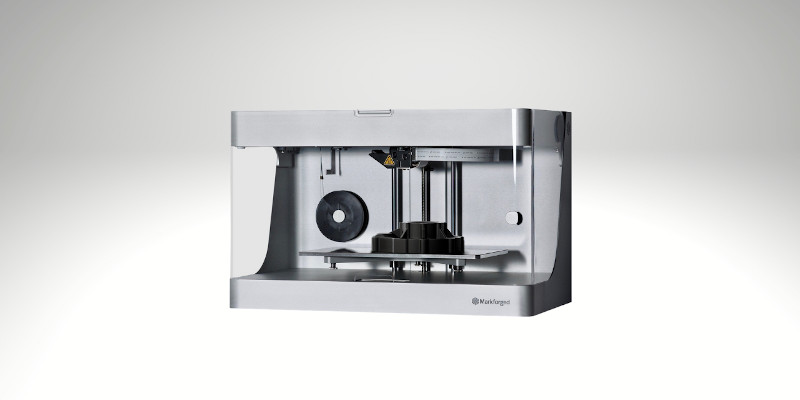

7. Markforged Onyx One — for high-quality carbon fiber 3D printing

- Price: $3,499

- Build volume: 320 x 132 x 154 mm

Pros

Offers great surface finishes and precision.

Great for designers and engineers.

Cons

Compatible materials for this printer are pretty expensive.

Markforged pioneered composite and high quality carbon fiber 3D printing with their professional FDM printer range, before expanding into metal 3D printers with their Metal X 3D printer.

For designers and engineers looking to print carbon fiber prototypes but without the $10,000+ for the Mark Two, the Onyx One is an ideal continuous carbon fiber 3D printer.

The Onyx One prints with Markforged’s specialized Onyx filament, offering great surface finishes and precision.

Onyx Filament

Specially designed for Markforged’s carbon fiber printers, Onyx is carbon fiber filled Nylon offering high strength, chemical resistance and excellent overall toughness. It can also be reinforced with continuous fibers as a continuous carbon fiber 3D printer filament for even better aluminum-level strength.

8. Desktop Metal Fiber HT & LT — Professional Continuous Carbon Fiber 3D Printer

- Price: $3,495 per year — request a quote here

- Build volume: 310 x 240 x 270 mm

Combining the exceptional performance of continuous carbon fiber with FDM 3D printing, Desktop Metal say their Fiber 3D printers produce parts stronger than steel, lighter than aluminum, and capable of operating in up to 250°C temperatures.

Desktop Metal use a process called Micro Automated Fiber Placement to apply continuous carbon fiber (or fiberglass) tape along critical load paths using the second extruder, while printing carbon fiber nylon filaments on the first. This creates denser, reinforced parts with excellent strength and low weight.

The Fiber system uses two print heads: one for either continuous carbon fiber (or fiberglass) tape, and one to deposit the carbon-fiber reinforced filament to make up the “shell” or “matrix” of the part. However, if you’re looking for versatility you can switch the materials and instead print with PEEK, PEKK, or PA6 Nylon.

The Fiber carbon fiber additive manufacturing system comes in two options: the Fiber HT, and Fiber LT, a more basic version. The main difference is the Fiber HT can reach high enough temperatures to 3D print PEEK and PEKK, whereas the LT edition prints with either carbon fiber or Nylon PA6.

- We also have a buyer’s guide for PEEK 3D printers.

Desktop Metal’s innovative business model lets you rent their industrial carbon fiber 3D printers for a yearly fee, rather than shouldering the entire cost upfront. This brings professional 3D printing into range for many more smaller companies looking to prototype or produce parts on-demand, making high-quality continuous carbon fiber 3D printing more accessible than ever.

Types of carbon fiber 3D printer

Chopped Carbon Fiber 3D printers

Chopped carbon fiber filaments are the main filaments used for standard FDM 3D printing.

Most of the lower cost options on this list print chopped carbon fiber filaments, which are tiny sub-millimeter carbon fibers mixed with a standard thermoplastic filament, such as Nylon, ABS, or PLA.

They make the filaments stronger, stiffer and more heat resistant, and print in mostly the same way as the standard filaments, just at higher temperatures and requiring an abrasive-resistant nozzle.

Continuous Carbon Fiber 3D printers

Continuous carbon fibers are long (unchopped and continuous) strands that are laid on top of the original chopped carbon fiber “shell” or “matrix”.

These continuous lengths of carbon fiber are deposited by a second extruder, creating even tougher parts than can absorb tough impacts and distribute heavy loads.

Tips for 3D printing carbon fiber:

- Hardened steel or ruby nozzle: these nozzles better resist the abrasiveness of carbon fiber filaments.

- Print at a higher temperature, as hardened nozzles are less thermally conductive: generally 260°C+.

- Larger nozzle size: se a slightly larger 0.5-0.6mm nozzle rather than a 0.4mm.

- Print slower than you would print standard filaments.