Key Takeaways

- Hot end upgrades: Hot end upgrades can improve the Ender 3’s printing performance, speed, and material compatibility.

- Micro Swiss All-Metal Hot End: A popular and affordable option that can print up to 300°C with various filaments. Easy to install and reliable.

- E3D V6 All-Metal Hot End: A standard and versatile option that can also print up to 300°C with different materials. Requires more effort to install but offers more customization.

- Creality Spider High-Temperature Hot End: A cheap and unique option that can reach up to 500°C for the most demanding materials. Similar to the stock hot end but with better features.

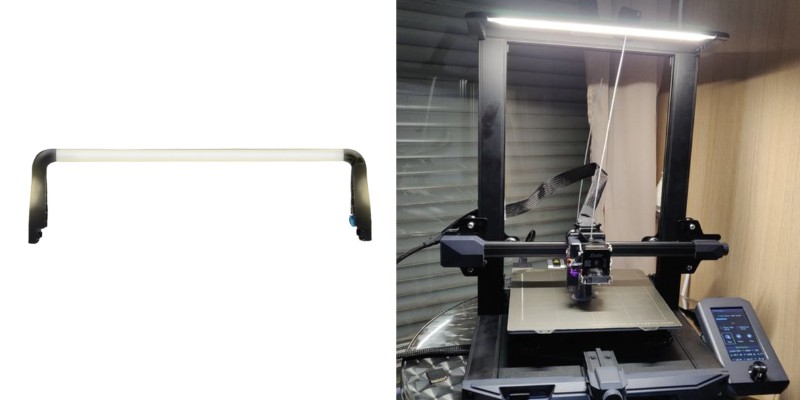

The stock Ender 3 configuration delivers a solid printing experience, but it’s possible to transform Creality’s flagship into an even better and more versatile 3D printer with the right upgrades.

Alongside an enclosure and new bed, an upgraded Ender 3 hot end is among the most popular if you want to increase print quality, speed, and variety of materials at your disposal.

|

4.4

|

4.5

|

4.2

|

|

$62.64

|

$63.50

|

$49.00

|

|

|

|

Overall, the Micro Swiss All-Metal Hot End is the option I’d recommend for most users due to its affordable price, ease of installation, and good performance with various materials.

Otherwise, the E3D V6 and Creality Spider High-Temperature Hot End are more expensive choices suited for users with more demanding 3d printing needs.

I’ll evaluate each upgrade I’ve tested based on their key factors, including price, maximum temperature, and compatibility with the Ender 3, Pro, and V2 models.

By the end of this article, you’ll have a better understanding of which hot end upgrade is right for you – so you can buy with confidence.

Best Ender 3 Hot End Options

Micro Swiss All-Metal Hot End For Ender 3

- Price: Check on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

Along with E3D, Micro Swiss is somewhat of a standard when it comes to 3D printer hot ends.

The company produces some of the most sought-after third-party components, loved for their precision manufacturing and reliability. The Micro Swiss All-Metal Hot End continues that tradition, all at a reasonably affordable $60 to $65, and full compatibility as an Ender 3 hot end upgrade.

As the name implies, the hot end is all-metal.

It has a Grade 5 titanium alloy heat break for superb thermal isolation between the heater and cooling block, also introducing a gap to the Ender 3’s PTFE tubing.

Additionally, the absence of a separate thermal tube inside the block means much speedier heat dissipation.

The Micro Swiss All-Metal Hot End can sustain temperature up to 300°C (Ender 3 firmware tweaks required), allowing you to print heat-sensitive materials like PETG, Nylon, PC, and ASA with the stock nozzle.

You can also swap in a hardened steel nozzle to extend filament compatibility to exotic and abrasive options like NylonX, carbon fiber, and NylonG.

As the Micro Swiss All-Metal Hot End requires no modifications to the Ender 3 or additional mounts to install, it’s among the easiest to set up.

Due to the V6’s popularity, there’s also no shortage of video tutorials to walk you through the process, including an official installation guide from Micro Swiss.

E3D V6 All-Metal Hot End (Works Great with Ender 3)

- Price: Check on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

Another top pick among Ender 3 owners who’ve taken the upgrade route, the E3D V6 All-Metal Hot End represents a standard for printer components thanks to the company’s focus on high-quality precision machining to deliver durable and versatile hot ends.

As an all-metal hot end, the E3D V6 hits 300°C with ease, opening the door to materials like Nylon.

E3D also offers the option of a copper heater block and hardened nozzle to print even more demanding materials like PC, Nylon, and PEEK.

The removal of internal PTFE tubing reduces the need for maintenance.

The heat break itself improves retraction performance thanks to a smooth inner surface finish, reducing oozing and stringing issues. E3D has integrated a cartridge-style mechanism for the heater block for easy replacement of multiple parts like the thermistors.

Installing the E3D V6 All-Metal hot end requires more effort than other options, but it’s well worth the extra steps.

Depending on your Ender 3 model, you may need to 3D print mounts and such, but the internet is awash with guides to walk you through every step of the process.

Creality Spider High-Temperature Hot End

- Price: $49 — Available at Creality store here / Check on Amazon here

- Max Temperature: 500°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

With third-party manufacturers like E3D and Micro Swiss making quite the splash in the Ender 3-compatible hot end space, it was only a matter of time before Creality swooped in with their own premium offering, the Creality Spider High-Temperature Hot End.

In line with the company’s longstanding commitment to affordability, the Creality Spider High-Temperature Hot End is among the more affordable options out there, priced at $49.

The hot end is also somewhat unique in that Creality says it can reach a maximum temperature of 500°C.

While the circumstances under which you’d want to push the Ender 3 that far are limited, the Creality Spider High-Temperature Hot End capably prints all types of filament, including the most demanding like Nylon, metal-filled, and PC.

Creality also throws around ‘worry-free high-speed printing’ up to 250 mm/s as a major selling point.

While we’d suggest avoiding such speeds if surface finish and detail matter, the Spider certainly improves print quality at higher-than-average speeds when using staples like ABS and PLA.

The Spider isn’t too far removed from the stock Ender 3 hot end in looks and assembly.

Creality has removed the inner PTFE tubing and introduced a copper alloy heating block for faster heating, a stainless steel heat break, and a tight throat tube with a low roughness finish to help retraction and filament flow.

Due to a larger footprint than the stock hot end, installation involves 3D printing an appropriately-sized fan cover or otherwise a gasket if you want a simpler option. Creality provides STLs for both.

Phateus Dragonfly BMS

- Price: Check on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

While established hot end brands like E3D and Micro Swiss warrant their popularity, their flagship products are arguably getting a little dated.

The Phateus Dragonfly BMS is a much more recent entry into the pool of Ender 3 hot end upgrade options. It’s a premium option at the cutting edge of consumer hot end technology that deserves far more attention.

Like the Creality Spider, the Dragonfly BMS boasts a max temperature of 500°C with material compatibility to match.

It can handle Ender 3 staples like PLA and ABS, and allows for printing TPU on the Ender 3 with good results along with:

- PETG

- PP

- PC

- PEEK

- PEI

- Nylon

- Carbon fiber

- Wood-filled

- Metal-filled

- Boron carbide

- Tungsten

This makes it one of the most versatile options around.

The Dragonfly BMS is made chiefly of copper alloy for faster heating and improved heat dissipation over the stock Ender 3 hot end.

It also features a unique conical fitting on the heat break, which also helps with dissipation and weaves in more distance to the Bowden PTFE tubing to avoid Ender 3 hot end clog problems.

Like the Spider, the heat break has a low roughness to improve flow and reduce retraction problems.

The quality of the parts and the construction quality is nothing short of excellent throughout, which translates to superior printing performance for the Ender 3. It’s also adapted for easy installation for the Ender 3, Ender 3 Pro, and Ender 3 V2.

For us, it’s the best hot end for Ender 3 despite being priced higher than more popular options.

E3D Revo Six

- Price: Check price on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

The E3D Revo Six is among the latest hot ends produced by E3D and is positioned as a direct upgrade for the E3D V6.

At its heart is E3D’s new RapidChange Revo, which allows toolless nozzle swapping based on your filament diameter needs.

Revo nozzles are available in 0.4 mm, 0.25 mm, 0.6 mm, and 0.8 mm color-coded variants, all brass and suitable for temperatures up to 300°C. Each nozzle includes not just the nozzle itself but also a heat break.

They arrive pre-assembled and factory-sealed, which simplifies installation greatly.

E3D says it plans to launch more nozzles in the near future, including wear-resistant options for abrasive materials and high flow variants.

As it stands, the E3D Revo Six hot end suits PLA, ABS, PETG, TPU, and Nylon printing.

As for changes compared to the E3D V6, the Revo Six features a Revo HeaterCore, the company’s cutting-edge heating and sensing technology. It heats faster and is reportedly much safer as it is designed not to melt at even the most extreme temperatures.

The E3D Revo Six boasts the exact same dimensions as the V6, making for an easy upgrade if you’re already running a V6.

As for upgrading a stock Ender 3 hot end, the process involves printing the correct mount.

With so much going for the Revo Six, why buy the V6? It all comes down to cost. The Revo Six is currently priced at around $100 while you can pick up a V6 for about half the price.

Creality Sprite Extruder Kit

- Price: Check on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

While upgrading the Ender 3’s hot end can drastically improve performance and extend material compatibility, another option is swapping the Bowden system for a direct drive extruder kit.

In this case, we have the very same Creality Sprite extruder found on the latest Ender 3 S1, which Creality kindly offers as a standalone upgrade kit for the Ender 3, Ender 3 Pro, and Ender 3 V2.

It combines an extruder and hot end in one.

As far as upgrades go, a Sprite extruder will have the biggest positive impact on the Ender 3’s performance.

Print quality improves, you can print flexible filament, and you do away with the Bowden-specific PTFE degradation and clogging issues that stock Ender 3 owners will be well accustomed to dealing with.

The Sprite features a 3.5:1 gear ratio, a high extrusion force, a tight filament path, and an all-metal design to provide more precise filament extrusion.

The kit also supports temperatures up to 300°C, making the Ender 3 compatible with more temperamental materials like PC and Nylon.

Although a significant upgrade, the Sprite is relatively straightforward to install.

It arrives as a complete assembly with a heat sink and fan, both instrumental in warding off heat creep and jamming issues. It’s designed to sit perfectly on the Ender 3’s existing mount for simple retrofitting.

E3D Revo Hemera

- Price: Check price on Amazon here

- Max Temperature: 300°C

- Ender 3 Compatibility: Ender 3, Ender 3 Pro, Ender 3 V2

The Revo Hemera is E3D’s latest and snazziest extruder/hot end combo.

Much like the Creality Sprite, it allows an easy upgrade path to a direct drive system and, of course, a brand new premium hot end.

The Hemera also features E3D’s new hot-swappable RapidChange Revo nozzle system, which is convenient if you use different filament diameters.

On the hot end side of things, the Hemera includes the same all-metal Revo HeaterCore as the Revo Six, making it suitable for all your main filament types along with Nylon and PETG.

E3D says abrasion-resistant Revo nozzles are on the way this year, so owners can look forward to printing with materials like carbon fiber-fill, Nylon X, and more exotic, abrasive materials before long.

As for the extruder, it’s a sleek direct drive system with 3.32:1 dual drive gears, a high pushing force (120N to the Sprite’s 80N) for ultra-accurate filament control, and stainless steel teeth for excellent grip, but also strong wear-resistance and reduction in build-up and clogging issues.

Also of note is the bespoke lightweight aluminum heatsink and fan setup. It works to feed air up and away from the printed part to reduce warping and eliminate heat creep.

E3D’s manufacturing is exceptional as expected, with a focus on details such as shielded bearing on the drive train and custom motor end caps to make installation as easy as possible.

Also, if you’d rather stick with the Ender 3’s Bowden extruder, E3D offers a special adapter for the Hemera.

FAQs

Articles we recommend:

- What are the best Ender 3 S1 upgrades?

- Ender 3 vs Ender 5

- The best Ender 3 firmware

- The best slicer For Ender 3

- Ender 3 dual extrusion upgrades

- The best Ender 3 software

- Ender 3 Alternatives

- Ender 3 filament guide

- Ender 3 fan upgrades

- Ender 3 direct drive upgrades

- Ender 3 auto bed leveling kits