Environmental concerns are more of a priority than ever, and a lot of us are doing our bit to lower our carbon footprint.

With rising concerns about plastic use, it’s only natural that the largely plastic-based 3D printer filaments are being looked at more carefully.

Biodegradable 3D printer filaments are more common than you’d think, and there are a lot of ways to make your 3D printing a much greener process.

As we’ll see today, plastic waste is avoidable, and there are plenty of biodegradable filaments to make 3D printing more eco-friendly.

Depending on how you want to cut down on plastic waste, and your budget, what kind of biodegradable filament you chose will vary.

Here we’re going to look at which 3D printer filaments biodegrade at what rates, and which you should go for depending on your priorities.

PLA

- Primary Ingredient: Cornstarch and other plant-based sugars

- Price: $20 – $50/kg

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Standard 3D printing projects, medical and dental tools, and kitchenware.

Beginning with a standard filament that you may have already used before, PLA is a bioplastic, which means that it is 100% biodegradable.

That is not to say that it won’t do some damage if disposed of incorrectly, however.

For PLA to live up to its 100% biodegradability, it needs to be done commercially. Properly recycling any wasted materials or failed PLA projects is the best way to keep it green. But you can also take care of it at home if you happen to have a home composting setup.

This is because PLA is only fully recyclable using very high temperatures and will need to be treated in a plant to be reused with any real efficiency. But it can still be composted at home.

It may interest you to know that there is ongoing research to make standard thermoplastics suitable for at-home composting too.

Wood

- Primary Ingredient: PLA and wood

- Price: $50/kg

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Puppets, sculptures, and anything else that would look better with a wooden veneer.

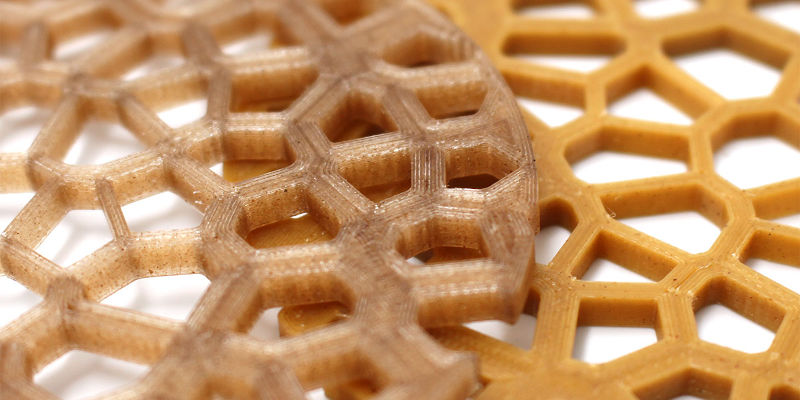

Despite how cool it sounds and the fact that you can alter the shade by changing the extrusion temperature, wood filament isn’t just made of wood.

Fortunately, the base for most wood filaments is made from PLA, meaning the filament’s natural biodegradability is left untouched.

Fillamentum’s Timberfill is one such PLA-based wood filament that is 100% biodegradable as well as a highly reliable filament.

You’re also not limited to only plywood when 3D printing, and you can find a host of different kinds like bamboo and cork to suit your printing needs. All of these filaments are biodegradable, non-toxic, and very eco-friendly.

Wood filaments are suitable for home composting and can be recycled just like any other good plastics, just don’t make the mistake of throwing them in with your garden waste.

It may look like wood, but the recycling plant won’t be too happy with that.

Paper

- Primary Ingredient: Paper Pulp

- Price: N/A

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Soft decorative items like pots and centerpieces.

It may seem like an unorthodox 3D printing material, but in an effort to help reduce paper waste, Dutch engineer Beer Holthuis developed a way to 3D print with paper.

This paved the way for a much greener way to 3D print using a famously biodegradable material.

With a process similar to laminating, CleanGreen 3D created a method that glues paper pieces together to make 3D printed objects.

The process wasn’t entirely green, though, as it did use some plastics to help the paper retain its shape. Though it was still much cleaner than a lot of other fully plastic-based methods.

While not as tough as standard materials, using paper as a biodegradable filament is a lot greener as it’s suitable for home composting, and works out quite a bit cheaper too.

Unfortunately, CleanGreen has gone out of business, but Beer Holthuis has continued his research in 3D printing directly with paper pulp, the details of which can be found on his blog here.

While not currently available to the public, continued research into 3D printing with paper will make for a much greener 3D printing experience for us all.

Coffee

- Primary Ingredient: PLA and coffee grounds

- Price: $20 – $50/KG + Your favorite coffee brand

- Suitable for Home Composting: Yes

- Toxic: Yes

- Best Used For: Decorative ornaments that you want to smell like coffee.

One of the more surprising additions to biodegradable filament development is coffee.

As an easily manipulatable substance that reacts well and predictably with heat, coffee makes for an excellent 3D printer filament that’s a lot easier to use than you’d think.

Like wood filament, coffee filament is PLA based, meaning it’s fully biodegradable.

It’s not only a cool way to get 3D prints with very satisfying colors (the prints even smell like coffee!) but it helps buff out your filament to give you more bang for your buck.

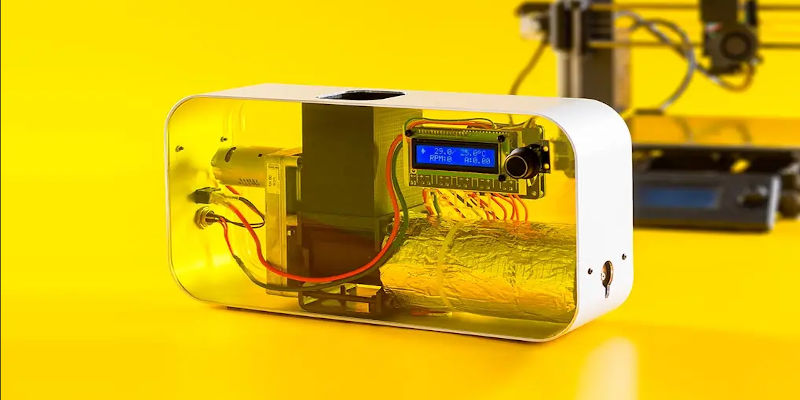

Coffee filament can be made at home with some simple PLA and store-bought coffee grounds.

This is simple to do. Using a filament customizer like a Felifil Evo extruder, you can easily make some fun and great 3D prints with coffee that are compostable and eco-friendly.

The only important thing to note here is that, despite its base ingredients, coffee filaments are toxic.

Because of its reaction to heat, the plastic will fray and seep into anything too hot in contact with it, so it’s not recommended to use coffee filaments for kitchen utensils.

If you’d like to know which 3D filaments are suitable for your kitchen, you can check out our full guide to food-safe filaments here.

Beer

- Primary Ingredient: Cereals and grains

- Price: ~$80/kg

- Suitable for Home Composting: No

- Toxic: No

- Best Used For: Decorative pieces with easily smooth finishes

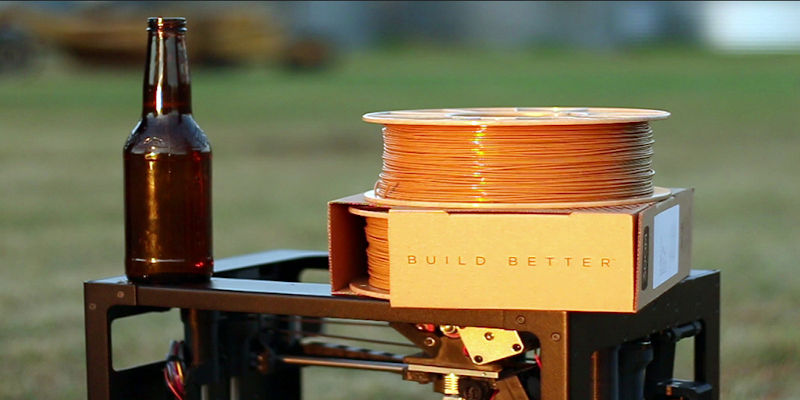

Okay, so this one got me excited.

The brewing process for all kinds of beer involves some byproducts that generally don’t or can’t be reused. Fortunately, most of these byproducts are all-natural like grains and cereals and can be composted without issue.

However, C2Renew, a company specializing in eco-friendly 3D printing solutions, found another use for these byproducts; 3D printer filament!

By turning these waste products into biodegradable filaments, they created a special filament called ‘Buzzed’ (clever, right?) that’s pretty much letting you 3D print with beer.

This is not only a very eco-friendly alternative to more harmful plastics but also gives unique finishes and ever-changing hues.

Traditional brewing processes are more random than one would think, and each batch will have a slightly different color to it.

While this does mean you can’t expect specific colors for your 3D printing needs, it does make each batch unique and makes for a different experience each time.

You can print the same project with each variety you get and compare them for some subtly different decorations.

Potatoes

- Primary Ingredient: Starch

- Price: N/A

- Suitable for Home Composting: Yes

- Toxic: No

- Best Used For: Kitchen utensils and decorative items.

Similar to the above example, potato processing produces a lot of compostable byproducts that can be turned into biodegradable 3D printer filament.

Like PLA, the main ingredient in these filaments is the starch that comes from potatoes and yams that would otherwise end up in a compost heap at best.

With a faster printing time than PLA, but lacking the general durability, potato and yam-based filaments are a much greener way to print. It’s also non-toxic, so imagine eating potatoes off a plate you made from potatoes! Trippy, right?

While not yet widely available for sale, more starch-based filaments are on their way and should enter the mainstream before too long.

Eco-Friendly 3D Printing Solutions

As well as using biodegradable 3D printer filaments, there are other ways to keep your 3D printing adventures eco-friendly and green as it gets.

Here are a couple of options you can apply to keep your environmentally friendly conscience clear while you print.

Recycle at Home

Home recycling and composting are good practices for eco-conscious people, and there are a lot of ways to do it.

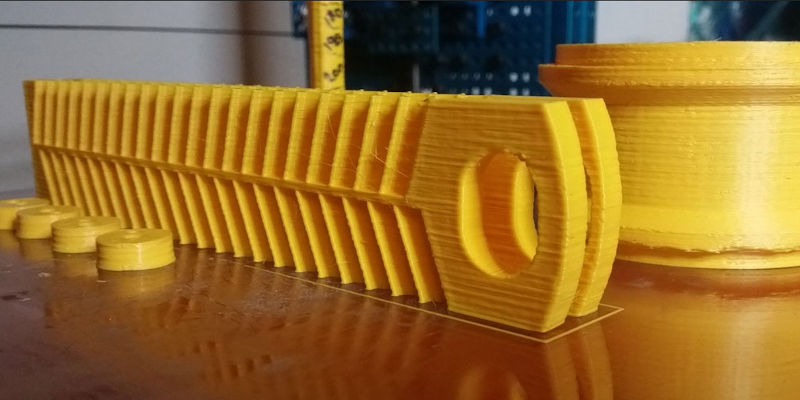

Machines like the ProtoCycler+ are desktop extruders that let you recycle old filament and even experiment with your own additives.

You will need this equipment if you plan on making your own coffee filament.

Keep in mind that you will also need a grinder or shredder to get your 3D filaments ready for recycling. All-in-all, this is by far one of the best ways to keep your 3D printing green as it basically makes wasted filament a thing of the past.

Buy and Use Already Recycled Materials

With just a little research, you’ll find there are plenty of companies out there that deal exclusively in recycled 3D printer filaments.

Reflow is one such company that specializes in sustainable 3D printing solutions, including recycled PETG 3D printer filament.

Because PETG is oil-based and therefore non-biodegradable, using recycled PETG is the best way to use it in an eco-friendly way.

Refilament also focuses on recycling otherwise non-biodegradable filaments like ABS and provides greener solutions to those of you who want something tougher than PLA but are still environmentally conscious.

Biodegradable 3D Printer Filaments FAQs

What filament is biodegradable?

PLAs are the most common biodegradable 3D printer filaments, but other materials like wood, paper, coffee, and hemp are being used as eco-friendly 3D alternatives to non-biodegradable filaments like ABS.

There have also been some innovations in biodegradable 3D printer resins that are currently available.

Is PLA filament actually biodegradable?

Yes. PLA is a fully biodegradable 3D printer filament but is best reused via a recycling plant.

Through home composting, PLA can take a very long time to degrade, whereas it takes a maximum of twelve weeks if done professionally.

Is wood filament biodegradable?

Yes. Being PLA-based, wood filament is fully biodegradable and suitable for home composting.

Given both its eco-friendliness and its awesome-looking results, wood is an ideal filament for 3D printing enthusiasts who want to go greener.

Is there environmentally friendly 3D printing?

By avoiding non-biodegradable filaments like ABS, 3D printing can be very environmentally friendly.

With proper recycling and composting, the carbon footprint of 3D printing is easily minimized. Industries that use 3D printing to create parts in-house are also more eco-friendly as it cuts down on importation and wasted material.

Other articles you may be interested in:

- The Complete Best 3D Printer Filament Guide

- Recyclable 3D printer filaments

- PLA 3D Printing Filament

- PVA Filament: The Complete 3D Printing Guide

- PLA vs ABS: Which is Best for your 3D Printing Needs?

- PLA vs PLA+: Is PLA Plus Filament better for 3D printing?

- Best ABS Filament: Top Brands & 3D Printing Guide