Circles are part of pretty much everything cool. You need them to make things like clocks or musical instruments. Your machine should be able to print round shapes, so if your circles are coming out as ovals, octagons, or blobs, it’s important to figure out what is going wrong and how to fix it.

This article covers the 3 main issues we’ve discovered during our 3D printing adventures, and exactly how we’ve fixed them, with some FAQs for other similar issues for getting the best circular results. With some simple troubleshooting, you can fix your issue and be back to perfect circle 3D printing.

The Main Reasons Your 3D Printed Circles Don’t Come Out Round – And How To Fix:

1. Loose Motor Belts

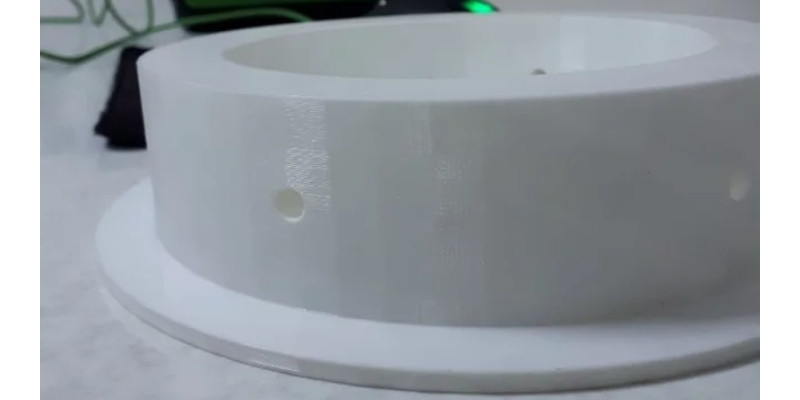

If you print a circle and it comes out looking more like an oval or a misshapen diamond, you probably have loose motor belts.

Loose belts will affect both a circular printed part and circular cut-outs, such as a hole for a screw.

How To Fix

To fix this problem, you need to tighten the belts of both the x and y-axis. Loosen the bolts and move the axis arm outward to tighten the belts. Screw the bolts back on, and that should fix your problem.

You’ll know if it has worked – the edges of your circle will be even and round.

2. 3D File is Too Simplified

If you try to print a circle but it comes out as a polygon with many straight sides, your STL file may have been reduced to a lower resolution.

In 3D printing, no lines are truly round. All circles are made up of many small triangles that come together to give the illusion of a curve.

How To Fix

If your piece has noticeable straight lines, the STL triangles are too big. Change your settings to print the file at a more detailed scale.

Be sure to select the finest resolution necessary for your project when exporting. Check your file in an STL viewer to verify that it looks round.

3. Extruder Incorrectly Calibrated

If your circle has warping or blobs, you might have incorrectly calibrated steps/mm. Your extruder controls how much filament is used in your print, and too much or too little filament will ruin a perfect circle.

Read more: Under Extrusion: Causes and How To Fix It

How To Fix

In your slicer, check to make sure your steps/mm are correct and recalibrate them if necessary.

Then you should have the proper amount of filament to make your circle round and sturdy.

FAQs

Related posts:

- How To Fix Issues With PETG Not Sticking to Bed

- Best Hairspray for 3D Printing Bed Adhesion Problems

- Complete Guide: 3D Print Not Sticking To Bed

- 3D Printed Home Décor Ideas For Your Home Or Gift Away

- Cool 3D Printing Projects for Engineers