Key Takeaways

- Average estimate: if using up 7 grams per hour, 1kg lasts approx 140 hours per spool, or 4-5 weeks for average user.

- Example prints: 1kg filament can print 63 Benchies, 4 flower pots, 16 pencil holders, 166 miniatures, or 4 Darth Vader busts.

- Tips to conserve filament: Reduce infill, supports, and print size; buy quality filament; store it properly.

A factory-fresh spool of filament promises possibilities, but eyeing it up doesn’t really give you a sense of how much you can print with 1 kg of filament, or how long it will last. Should you make the most of a multi-spool deal, or settle for one 1KG roll?

As with most things in 3D printing, your mileage will vary – everyone has different printing plans and uses different settings that can affect filament use, like infill density.

I’ve created a filament calculator in this article, to help you understand how many prints you can get out of a spool of PLA, and how many hours of continuous printing a kilo of filament will get you.

I’ve also estimated filament usage per hour, using a blended average of popular STL files in Cura, and how many of these you can print in an average 1kg spool.

So, whether you’re printing full-sized Master Chief helmets, flower pots, or churning out batches of miniatures for tabletop gaming, this article has you covered.

So, How Long Does a 1kg Spool of Filament Last?

Based on a 3D printer usage of 7 grams of material per hour, a 1 kg spool of filament will last 4.5 weeks if you 3D print for 30 hours per week.

Running the 3D printer 24/7 will use up a 1kg PLA filament spool in 143 hours, or roughly six days. For casual users who only use their 3D printer once a week for five hours, a spool will last 28.5 weeks, or a little over six months.

Here’s a calculator to help you estimate exactly how long your filament will last. Input your filament spool size, how often you 3D print, and the calculator will give you an exact answer:

Filament Usage Calculator

Days the spool will last: 0

Weeks the spool will last: 0

Years the spool will last: 0

However, filament usage depends on how much you 3D print, the size of your prints, and your slicer settings like infill density, wall thickness, and print speed. Larger prints like tabletop terrain, cosplay parts, helmets, and large vases also use filament much faster than smaller parts like miniatures and small household items.

To reach our estimate of 7 grams of filament per hour, we took several common 3D print STL files and found their print times and filament use per hour in Cura. We then averaged these results.

Here are the three sample models we used:

| Model | Filament volume used (grams) | Print time (hours) | Filament volume used per hour (g/hr) |

|---|---|---|---|

| 3D Benchy | 16 | 3 | 5.33 |

| Happy Pot | 221 | 24 | 9 |

| Square Pencil Cup | 63 | 9 | 7 |

This gives us a solid starting point to estimate how much filament is used in 3D printing, and how long a 1 kg roll of filament will last the average user.

From there, we can calculate how long it will take to use up a 1 kg spool of filament:

| Printing time | Filament used up on average |

|---|---|

| 1 hour | 7 grams |

| 10 hours | 70 grams |

| 24 hours | 168 grams |

| 100 hours | 700 grams |

| 1 week | 1,176 grams |

To summarize, a 1 kg spool of filament can last anywhere from a week to six months, depending on how often you use your 3D printer.

How Much Can You Print With 1kg filament?

With 1kg of filament, you expect to print roughly 63 3DBenchy test prints of approximately 16g of filament each. Other example models you could print with 1kg filament are 4 large flower pots, 16 pencil holders, around 166 miniatures, or 4 large Darth Vader busts.

However, this doesn’t factor in any failed prints, so you should be conservative with these estimates.

Breaking this down, we can see how this works based on the gram per model consumption established above:

| Model | Grams per Model | Models per 1 kg Filament |

|---|---|---|

| 3DBenchy | 16 grams | 63 models |

| Large Flower Pot | 221 grams | 4 models |

| Pencil Holder | 63 grams | 16 models |

| Miniatures | 6 grams | 166 models |

| Darth Vader Bust | 236 grams | 4 models |

Should you want an estimate more suited to your particular model, settings, and printer, we recommend loading it up in your slicer and slicing the model.

This will give you not just a print time estimate, but also how much filament in grams is required for the print. Though numbers can sometimes be a bit off, they offer a solid estimate to guide you.

Factors That Affect How Long Filament Lasts

- Supports

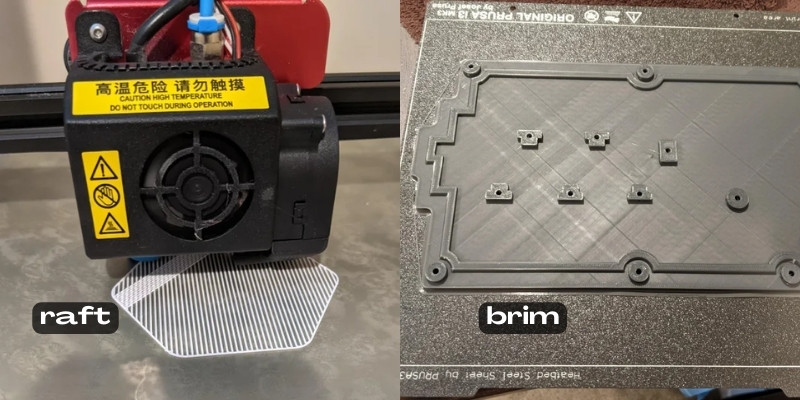

- Skirts/Brims/Rafts

- Infill Settings

- Downsize and Print Selectively

- Filament Quality and Maintenance

1. Supports

Support structures are a vital part of 3D printing, especially when printing ambitious projects with lots of overhangs and rich details.

However, supports use up filament. The more supports you use, the less mileage you’ll get out of a 1 kg spool of filament.

The key to mitigating wasted filament is to be economical with supports – only use them where necessary, and angle your prints correctly in your slicer to require the least supports possible.

Manually adding supports where needed generally uses less filament than auto-support wizards and tools found in most slicing software.

2. Skirts/Brims/Rafts

The same applies to skirts, brims, and rafts. They are vital tools for preventing first-layer adhesion issues, but, again, cost filament.

This isn’t a huge amount generally, but if you’re a heavy user you’ll use quite a bit of filament over time, reducing how many prints you’ll get per 1 kg spool of filament.

To reduce unnecessary filament waste, cut down on the number of layers, the width, and infill density of brims and rafts, and reduce the number of lines that form a skirt.

3. Infill Settings

Infill settings arguably have one of the biggest impacts on filament consumption. By reducing the infill density percentage, you can significantly increase how many prints you’ll get from a spool of filament.

While 20% infill is a common standard in most slicer software, for many prints you can get away with lowering this by a few percentage points, even as low as 0-5% for decorative prints that won’t be subject to wear and tear or functional applications.

Similarly, different infill patterns use different amounts of filament and have different advantages.

If you’re after the most economical patterns, options like Line, Lightning, and Zig Zag tend to use less filament than other patterns. If you’re looking for a balance between material consumption and strength, use infill patterns like Hexagon.

It’s also worth using settings like gradient infill to instruct the printer to use a higher infill density on the outer edges of the print, while reducing it as it nears the center.

4. Downsize and Print Selectively

Though large prints are certainly impressive, they aren’t always necessary, especially for decorative items. You can conserve filament by downsizing your prints.

Dropping the print size to 80%-90% won’t have a major impact on the part, but saves you lots of filament over time.

In the same vein, be more selective over what you print. All makers are guilty of printing parts and models that end up sitting on a shelf or in a workshop serving no purpose whatsoever. This filament could have been put to better use.

In that spirit, it’s worth really thinking about whether you need an extra flower… or if you really need a fifth bust dedicated to your favorite blockbuster franchise (yes, you probably do). Cutting back where appropriate can greatly extend the lifespan of a spool of filament.

5. Filament Quality and Maintenance

As tempting as it is to buy the cheapest filament, it often comes with downsides, whether that’s a shoddy formula, poor manufacturing, or an approximate diameter, length, or weight. Not all 1 kg spools actually weigh 1 kg when you receive them…

In other words, get your money’s worth by spending a little more on better-quality filament. This also reduces failed prints that can happen because of low-quality filament. We personally have a guide to the best PLA filaments, and best filament brands overall.

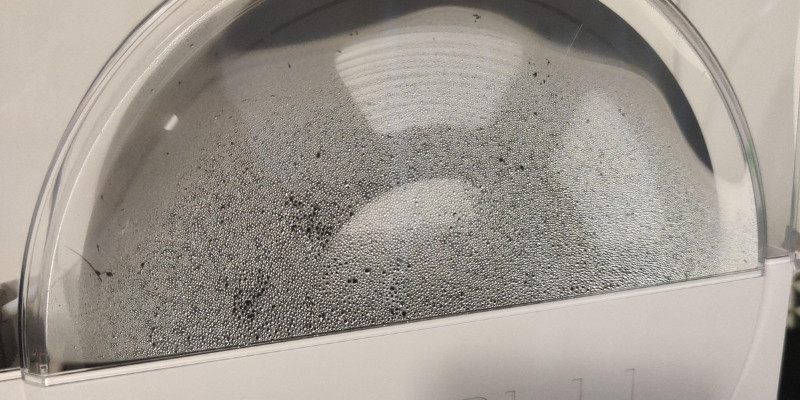

Another important part of conserving filament is to store and maintain it properly. Almost all filament are hygroscopic, meaning they absorb moisture if left in the open air and deteriorate over time.

To avoid this, we recommend investing in dry boxes or even a filament dryer. These do all the heavy lifting to keep your filament in top condition.

Related articles:

- How much can you print with 1L of resin?

- Complete Guide: Layer Height In 3D Printing

- Best Filament Dryers & Dry Boxes in For All Type of Budgets

- Make Your Own Filament Dry Box: Projects You Can Make at Home

- Top Ways to Recycle Empty Filament Spools

- Increasing Strength While Saving Filament by Using 3D Print Infill Settings

- How-To: Dry Your Wet Filament Effectively