Key Takeaways

- Shrinkage definition: Shrinkage is the reduction in size of a 3D printed object due to thermal contraction of the filament as it cools down.

- Shrinkage factors: Shrinkage depends on the type of filament, the printing temperature, the cooling rate, and the ambient temperature. Higher-temperature filaments tend to shrink more than lower-temperature ones.

- Shrinkage rates: PLA has a shrinkage rate of 0.2% to 3%, ABS has a shrinkage rate of up to 11%, and PETG has a shrinkage rate of 0.6%. These rates may vary depending on the brand and color of the filament.

- Shrinkage compensation: Shrinkage can be compensated by scaling up the dimensions of the 3D model, adjusting the horizontal expansion setting in the slicer, or using a heated bed and an enclosure to control the temperature.

Although it’s hard to notice, your 3D print doesn’t come out with the exact dimensions as your STL file. Whenever this happens, we call it shrinkage. Because the shrinkage is only a few millimeters, it’s typically hard to miss.

If you’re printing something to put out on display, some mild shrinkage shouldn’t raise any concerns.

But, shrinkage becomes important if you need the measurements of your print to perfectly match those of your CAD model, for example when printing prototypes, phone cases, or precise miniatures.

In this article, I will unpack the meaning of shrinkage and explain how it occurs. I’ll also talk about how much PLA, ABS, and PETG usually shrink. Lastly, I’ll offer a few tips on how you can compensate for shrinkage whenever you print.

What Is Shrinkage In 3D Printing?

Shrinkage refers to a reduction in the size of a 3D printed object. When molten 3D printing filaments cool down, they contract, and the print becomes slightly smaller. Although the filament expands under heat, it eventually shrinks due to the drop in temperature when it leaves the printer’s nozzle.

Shrinkage is a common issue because FDM 3D printers have to melt plastic to create the print.

So what happens as a 3D print undergoes shrinkage?

How Shrinkage Occurs

Shrinkage all comes down to the chemical properties of the filament used to print. Filaments are thermoplastics, so they melt when heated and solidify when cooled.

When the melted filament is deposited on the print bed, the outside temperature makes it cool. Like most materials, the object will contract slightly via thermal contraction as the temperature drops.

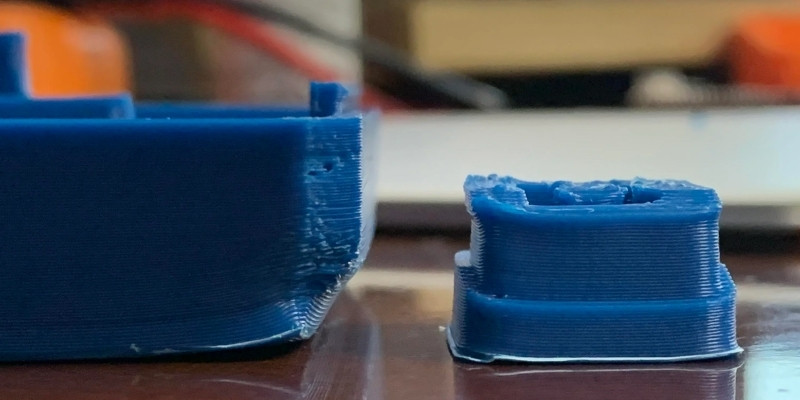

Unfortunately, the shrinking process also causes warping in your 3D prints, especially when working with high-temperature filaments.

Warping occurs due to filaments cooling too quickly – that’s why printers typically have a heated bed to cool slower, and enclosures for better heat maintenance. Warping isn’t really a problem with PLA, but is with ABS and other higher-temperature filaments.

Now that we know what shrinkage is, how does it come about?

What Causes Shrinkage In 3D Printing?

Shrinkage is caused by different factors, including:

- Printing temperature

- Cooling speed

- Printing technology

- The material used for printing

Printing Temperature

Every filament has its ideal extrusion temperature, which is vital to achieving successful results. PLA prints at 180 to 230°C. ABS’ printing temperature is slightly higher at 210 to 250°C, while PETG extrudes between 220 and 250°C.

In addition to the printing temperature, some 3D filaments need a heated printing bed to prevent warping and provide extra adhesion.

Filaments that print at higher temperatures generally shrink more than those that print at lower heat – for example, ABS shrinks more than PLA.

Cooling Speed

As mentioned, shrinkage happens at the cooling stage of the printing process. The ambient temperature can also make or break the geometrical accuracy of your print. If the freshly printed object cools down too quickly, it’ll experience much more shrinkage than when it cools down in an enclosure.

Printing Technology

The type of printer largely determines the amount of shrinkage to expect in your mold. While FDM printers are affordable and easy to use, other technologies such as SLS printers are far better for performing under strict tolerance expectations.

The Filament Used For Printing

While the above factors significantly contribute to shrinkage in 3D prints, the major culprit is the type of filament you choose. Let me explain why.

Every filament behaves differently when cooling. As it cools down, shrinking will only happen once the temperature drops below the glass transition temperature.

Before a thermoplastic melts, it reaches its glass transition temperature, where it changes from its original rigid state to a rubbery material.

During cooling, the liquefied filament’s temperature will drop to the glass transition temperature. At that point, the model is not as brittle as the final print, but it’s not exactly a liquid either. This is where shrinkage begins.

As a result, shrinkage is much more common in filaments with a high glass transition temperature.

To sum it up, since glass transition temperatures vary across filaments, one filament might shrink more than another. In some cases, different brands of the same filament will have different shrinkage rates. Additionally, ambient temperature and the rate of cooling may not be the same whenever you print, adding to the variation in shrinkage percentages.

Let’s have a look at the numbers.

How Much Does Each Filament Shrink?

PLA

Polylactic Acid (PLA) is one of the most widely used 3D printing materials. It is biodegradable, non-toxic, and obtained from renewable sources like corn starch.

With a shrinkage rate of 0.2% to 3%, PLA is one of the filaments less prone to shrinking. This is because PLA is a relatively low-temperature filament, printing at a nozzle temperature of around 180 to 230 degrees celsius.

Printing with PLA doesn’t always require a heated bed, but using one goes a long way in reducing warping.

The idea is to set up a strong base layer that will hold the entire print. Therefore, keeping the bed temperature at about 50 degrees celsius will keep the lowest layer nice and strong for the rest of the model to sit on.

ABS

Acrylonitrile Butadiene Styrene (ABS) was one of the first 3D printing materials to be used in the industry. Its high tensile strength makes it a sought-after filament for making rigid, long-lasting objects and toys.

However, ABS has one of the highest shrinkage levels at up to 11%. The amount of shrinkage heavily depends on how the filament was manufactured, its brand, and sometimes color.

Slicer settings are often set to account for ABS shrinkage, with around a 2% increase in size often used among hobbyist makers.

Many variants and combinations of ABS are used today. Here are some of them and their range of shrinkage.

| ABS Variant | Minimum Shrinkage (%) | Maximum Shrinkage (%) |

|---|---|---|

| ABS – Acrylonitrile Butadiene Styrene | 0.7 | 1.60 |

| ABS High Heat | 0.4 | 0.9 |

| ABS High Impact | 0.4 | 0.9 |

| ABS/PC Blend | 0.5 | 0.7 |

| ABS/PC Blend 20% Glass Fiber | 0.2 | 0.3 |

| ABS/PC Flame Retardant | 0.3 | 0.6 |

(Source: Omnexus)

Besides requiring higher print bed and nozzle temperatures, ABS is notoriously sensitive to temperature changes during the printing process. It also cools much slower than PLA, so it requires steady temperatures. Otherwise, a sudden fluctuation in temperature may create a deformity in the printed object.

To ensure your ABS prints don’t shrink too much, it’s necessary to regulate the temperature as you print. The best way to do this is by printing inside an enclosure. The enclosure keeps the heat around the mold uniform while blocking out external cold air.

PETG

Polyethylene terephthalate glycol (PETG) is a high-performance filament that delivers a unique mix of high tensile strength, chemical resistance, and non-toxicity.

Like PLA, PETG is one of the least susceptible filaments to shrinking. With an average shrinkage rate of only 0.6%, the material is ideal for making detailed models with accurate dimensions.

As we’ve seen, shrinkage is second nature to thermoplastics. Since we cannot do away with it, the best solution is to plan for it in our designs through shrink compensation.

How To Compensate Against Shrinkage

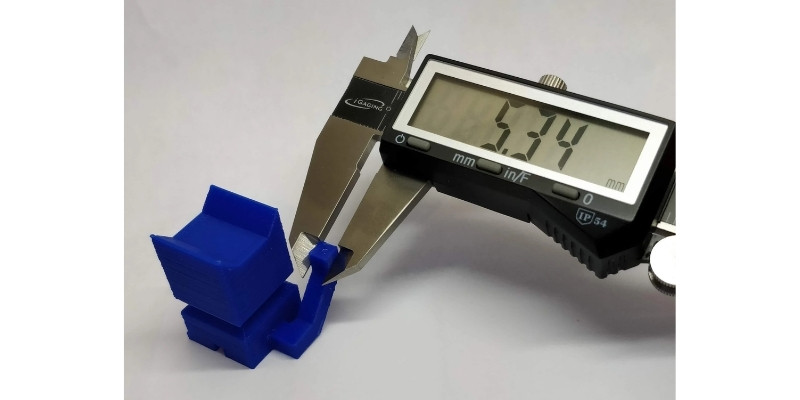

If you want to reduce shrinkage in your 3D models, scale up the dimensions of your design by the shrinkage rate of the material you’re using to print. To calculate the shrinkage rate, compare your 3D model’s dimensions with those of the image in your software.

The shrinkage rates provided earlier can serve as a guide on what to expect. But as mentioned earlier, different brands of the same filament can have varying degrees of shrinkage, owing to additives and color differences.

So a sure-fire way of getting the desired measurements in your print is to actually know the amount of shrinkage you’re working with at your setup.

To find the shrinkage of the filament you’re working with:

- Select a particular filament and print your model.

- Using a digital vernier caliper gauge, measure the dimensions of the finished model and record them down.

- Subtract each measurement on your object from its corresponding value in the 3D model.

- Multiply your results by 100% to get the shrinkage rate.

You can also reduce the amount of shrinkage in your prints by tweaking a setting called Horizontal Expansion. This slicer setting lets you configure a compensation value for the 3D object. In other words, it allows you to print a slightly larger figure so that you get the desired dimensions after it shrinks.

Compensating for shrinkage is usually not a one-off attempt. You’ll have to test out a couple of prints before you figure out the correct values to use to offset shrinkage changes. Still, it’s an excellent way to get pinpoint accuracy on your 3D prints without spending a fortune on high-end printers.

Sources

Other related articles:

- How to anneal your 3D prints for strength

- 3D prints warping or curling? – Why It Happens and How to Prevent It

- What is the difference between TPE and TPU flexible filament?

- How to improve PETG adhesion so it sticks to your print bed

- Everything you need to know about PETG glass transition temperature