3D printed casts were pretty underwhelming when they were first introduced in 2013.

Now a decade later, we’ve seen notable improvements to produce ortheses that are comfortable, effective, and helping patients get back to their normal, active lives.

From fully 3D printed casts to design software, there are now plenty of options to help professional physicians treat broken bones and bad sprains.

In this guide I’ll share the most impressive 3D printed cast projects, as well as the technological developments that are underpinning their efficacy.

3DSourced Picks

- Cortex Cast – Breathable Support for Localized Fractures

- CastPrint – Specialized Solutions for Arm and Leg Injuries

- Xkelet – Rapid Production with Reusable Design

- Exiom – Efficient Customization for Active Lifestyles

- Activarmor – Comfort and Normalcy in Recovery

- Cast21 – Compassionate Healing with Reliable Design

- Spentys – Cost-effective and Tailored Treatment

- Invent Medical – Diverse 3D Printed Orthopedic Solutions

- Artus3D – Championing Athlete Recovery with Modern Tech

- Mercuris – Precision in Every Print

Best 3D Printed Casts 2023

Cortex Cast

- Best for: Offering localized support for fractures with a breathable design.

- Price: N/A

- Learn More: Evill Design

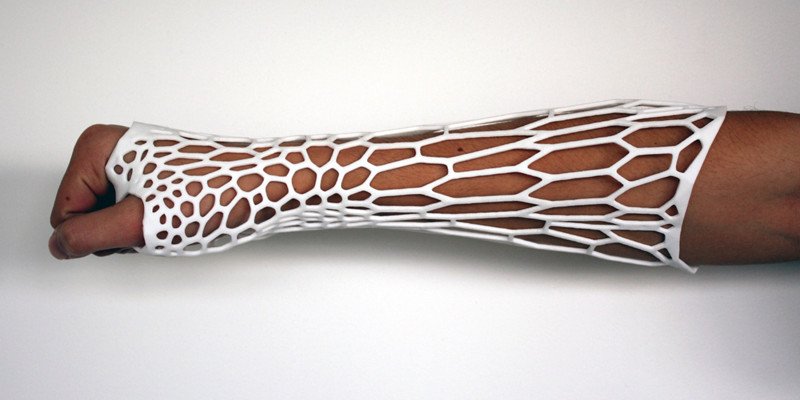

New Zealand engineers Ollie and Jake Evill created the Cortex Cast in 2013, a groundbreaking 3D printed orthopedic cast. This high-tech, breathable, and lightweight cast offers localized support for fractures, a previously unattainable feature.

The Evills’ innovative work placed second at the International James Dyson technology awards and led them to design roles in the Hollywood blockbuster, Blade Runner 2049.

CastPrint

- Best for: Producing unique casts for specific arm areas and being among the initial innovators of 3D casts for leg injuries.

- Price: ~$110

- Learn More: CastPrint

Latvia-based CastPrint was founded by entrepreneurs Janis Olins and Sigvards Krongorns, pioneers in the 3D printed cast industry. It produces unique casts for specific arm areas such as the wrist, thumb, and fingers, and is among the initial innovators of 3D casts for leg injuries.

Having achieved prominence in the Latvian healthcare sector, they have recently entered the UK market, gaining adoption by numerous private healthcare firms. CastPrint’s rapid expansion suggests an imminent continental dominance.

Xkelet

- Best for: Reducing production time and enabling recasting of the same injury multiple times.

- Price: $200 – $500

- Learn More: XKast

Spanish startup Xkelet is revolutionizing 3D printing casts, aiming to reduce production time from 2 hours to 12-30 minutes. COO Tim Dobrinich spearheads this goal using a specialized iPad camera attachment and app to photograph patients’ limbs from all angles, bypassing lengthy 3D scanning and modeling.

Their unique design employs reusable anchor points, or o-rings, enabling recasting of the same injury multiple times.

Exiom

- Best for: Rapid design and production of high-quality casts that allow patients to lead normal, active lifestyles.

- Price: N/A

- Learn More: Exiom

Naming themselves the pioneer of next generation orthopedic bracing, Exiom make sure their high-quality casts are designed, fitted, and printed as fast and efficiently as possible while maintaining product quality.

Using CAD software, they can rapidly make casts perfectly suited to each patient’s injury and limb. Their custom-created 3D printed casts are made quickly and efficiently.

Their main promise to their clients is that they can continue to lead normal, active lifestyles even while wearing their cast. They are waterproof and easy to remove and clean, so patients can take a shower and bathe without needing to tie a garbage bag around their injured limbs.

Activarmor

- Best for: Ensuring patients can continue their daily activities, including swimming, without hindrance.

- Price: Only available on request

- Learn More: Activarmor

Like Exiom, Activarmor is a revolutionary 3D printed cast company that focuses on its patients’ comfort and ability to continue life as normal even when having to wear a cast.

One testimonial from a 19-year-old lifeguard attests to this, saying they were still able to swim and perform their duties as needed even after having surgery on a broken wrist. Such things wouldn’t be possible with fiberglass casts, which need to stay dry to avoid skin irritation and infection.

Physicians seem to love it as well as patients, praising the quality of the product and its effective cost-cutting benefits. Since each Avctivarmor cast is printed as needed, there’s no inventory or need for extra supplies like splints, cutting costs drastically.

Proper healthcare is important to Activarmor too. They call their products the world’s first sanitizable casts, as they’re not only easily removable and easy to clean, but also are designed to make sure they don’t trap dirt or bacteria like traditional casts. All Activarmor casts are also 100% recyclable, meaning you can dispose of your cast in an environmentally friendly way once you no longer need it.

Cast21

- Best for: Combining compassionate care with some of the most reliable 3D printed casts on the market.

- Price: Depends on severity of injury and insurance

- Learn More: Cast21

Cast21 offers compassion as well as promoting healthy healing, making sure patients are comfortable while they recover.

The largely female-led company has developed some of the most reliable 3D printed casts on the market since their founding in 2016. They’ve also been very public in promoting news and studies about the present and future of 3D printed casts, making sure everyone is aware of the kind of innovations they’re bringing to the medical field.

Spentys

- Best for: Offering a cost-effective solution with high-resolution 3D scanning, modeling, and printing tailored to each patient.

- Price: N/A

- Learn More: Spentys

Spentys 3D printed orthopedic casts offer a cost-effective way for physicians and other professionals to treat various conditions.

Their process involves high-resolution 3D scanning, modeling, and printing casts unique to each patient and their conditions, be them temporary or chronic, to aid in recovery and keep their clients happy, comfortable, and healthy along the way.

Spentys offers the 3D printing cast service themselves too. They do this by looking over your design to make sure the casts are printed perfectly every time.

And you shouldn’t be worried if you have no CAD or 3D modeling experience, as Spentys offers an easy to understand, streamlined experience with their guided workflows from scan to print for anyone who’s willing to learn.

Invent Medical

- Best for: Providing a range of products including standard splints, cranial remoulding helmets, and protective face masks.

- Price: N/A

- Learn More: Invent Medical

As a global leader in new orthopedics and 3D printed casts, Invent Medical offers amazing new products in their 3D printed line, including standard splints, cranial remoulding helmets for babies, and protective face masks for facial injuries.

For professionals interested, but not experienced, in using 3D printed solutions for treatments, Invent Medical ensures full support from scanning to printing.

To find out more about what Invent Medical has to offer, you can check out their online showroom for a full tour.

Artus3D

- Best for: Assisting athletes in their recovery journey

- Price: Variable

- Learn More: Artus3D

Artus3D aids in accessibility of modern technologies by offering their services to any medical company who wants to provide their patients with new 3D printed orthopedic solutions.

Artus3D had already cemented itself as an invaluable resource for 3D printed casts and splints, but they really made their mark when one of their designs helped Dutch hockey legend Eva de Geode rejoin her team after breaking her wrist in 2021. Wearing this brace, her and her team went on to win the EuroHockey championship against Germany.

Mercuris

- Best for: Aiding patients with complex prints for recovery.

- Price: Up to $495/month

- Learn More: Mercuris

With their step-by-step guides, Mercurius helps from scanning to creation and even helps you make sure your model is a perfect fit for your patient before printing begins.

Regardless of complexity, Mercuris ensures exact prints every time, making sure patients get exactly the equipment they need for healthy recovery.

If you’re interested in the Mercuris systems, you can check out what they offer on their official site.

How do 3D Printed Casts Work

Creating 3D printed casts involves three steps

- A standard x-ray is taken of the patient’s limb to identify the exact position of the broken bone.

- The patient’s arm is scanned using a 3D scanner to create a 3D model. Based on the exact dimensions of the patient’s arm, a perfect-fitting cast shape can be made.

- Using strong but lightweight plastic, the cast is 3D printed and can then be fitted to the patient in seconds.

The Pros and Cons of 3D Printed Casts

Benefits of 3D printed casts

Cheaper

3D printed casts, like those from CastPrint, are a more economical treatment option, costing roughly $100 compared to the traditional plaster casting’s average cost of $856 per patient, according to UK National Health Service data. The affordability is primarily due to reduced material costs and decreased specialist time.

More Comfortable and Personalized

A 3D printed cast offers a targeted, more comfortable healing experience than a plaster or fiberglass cast. Their open lattice structure improves breathability, enhances comfort and maintains mobility, especially beneficial for children during bone healing, making them a real game changer.

Reusable

3D printed casts, notably Xkelet, promote cost reduction through reusability. Their adaptive design ensures efficient material use and quicker processes. This approach far exceeds using multiple traditional plaster casts in terms of cost and effectiveness.

Disadvantages of 3D printed casts

Leg Injuries Still Not Widely Treatable

Despite CastPrint’s development of leg casts, only a handful of global companies offer similar products. Although sturdy and lightweight, these casts are bulky and resemble traditional walking boots, posing challenges in wearing socks and shoes, and providing less freedom than arm-based equivalents.

Not Enough Data

Despite being around for a decade, with Cortex Cast being revealed in 2013, 3D printed casts have yet to see significant adoption. But as we learn more and patient testimony becomes more common, we’ve already seen a rise in the use of 3D printed casts since 2022.

A 2021 study revealed excellent healing with 3D printed casts in children without sacrificing comfort or making any significant lifestyle changes while wearing their casts.

How 3D Printed Casts Are Improving Outcomes

Ease of Fitting and Removal

3D printing enhances the plaster cast application and removal process. Its efficiency eliminates the lengthy, intricate task of manual bandage application, reducing discomfort. Fitted rapidly using a few clips, 3D printed casts are equally simple to remove, circumventing the need for potentially harmful electric saws.

Breathability and Infection

Plaster casts have a key downside: they block airflow, leading to blocked pores, potential skin infections, discomforting itchiness, and skin irritation due to trapped warmth and sweat.

On the contrary, 3D printed casts, with their lattice structure, allow for ample air contact. The large open sections, held together by plastic struts, maintain structural integrity without entirely covering the limb, contributing to the significantly higher comfort rating as observed in medical studies.

Waterproof

Unlike traditional casts, 3D printed casts can be safely exposed to water, unlike traditional casts which need to remain dry at all times to prevent irritation and infections.

Personalization

Any 3D printed cast will have a lattice design, offering a significant advantage over a traditional plaster cast. Unlike the latter’s one-size-fits-all methodology, which can hinder healing due to uneven pressure distribution, a 3D cast provides patient-specific support with a custom fit. This approach focuses on specific areas needing reinforcement, while ensuring comfort and accelerating recovery.

The Future of 3D Printed Casts

More 3D printed cast companies are being FDA approved, meaning these casts are now acknowledged by governing bodies for their benefits in the medical field. The casts have improved patient satisfaction compared to traditional casting, and many insurance companies will even cover them now, meaning we should see a significant rise in the use of 3D printed casts and other orthoses going forward.

Other articles you may be interested in: