PEEK and Ultem 3D printing is set for huge growth in the coming years, predicted to become a $1.1 billion industry by 2026, accounting for 19% of polymer 3D print material revenues. Companies are turning to PEEK 3D printers to save weight, improve strength, and create the next generation of high performance prototypes.

So, we’ve highlighted the top high-temperature 3D printers for 3D printing PEEK, ULTEM, and related materials.

The Intamsys Funmat HT is a versatile, affordable industrial 3D printer.

It uses interchangeable hotends for printing standard and abrasive filaments like PEEK with accuracy and effectiveness.

- This article focuses on the best PEEK 3D printers. We also have an article on PEEK 3D printing.

Best High-Temperature 3D Printers For PEEK & Ultem

1. Intamsys Funmat HT Enhanced — affordable PEEK 3D printer

- Price: $7,499 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

Pros

One of the cheapest PEEK 3D printers available.

The hot end is capable of reaching 450°C.

Can readily print Ultem PPSU and other similar materials.

Light weight despite the heavy metal frame and the insulated heat chamber.

Cons

Difficult to upgrade.

One of the cheapest PEEK 3D printers available, the Intamsys Funmat HT Enhanced still offers great precision and a specialized thermal system for handling everything required in a 3D printer for PEEK material.

This thermal system includes an all-metal hot end capable of reaching 450°C, high quality heated bed that can reach 160°C, and a choice of two extruders — one for high temperature PEEK, Ultem or PPSU 3D printing, and one for standard 3D printer filament printing like ABS, PETG, and PLA.

The Intamsys Funmat HT Enhanced is a 3D printer for PEEK, and can readily 3D print Ultem, PPSU and other similar materials. The 50-micron minimum layer height means it’s more than capable of the intricate precisions important for rapid prototyping and functional part printing, and it has been used in aerospace, automotive, engineering and medical part uses.

Overall, it’s a great entry-level PEEK 3D printer, weighing just 43kg despite the heavy metal frame and carefully insulated heated chamber for precise heat maintaining during printing. The built-in camera makes for more effective monitoring of PEEK prints, and less errors leading to costly ruined prints.

2. Tractus T850P — great high temperature 3D printer

- Price: $15,000

- Build volume: 280 x 280 x 400 mm

Pros

Large print sizes despite the size.

Can print quickly, even with PEEK, up to 450mm/s.

Functions well with more standard filaments along with printing PEEK.

Cons

The small size will turn people off given the price.

Given the size, you wouldn’t think the Tractus T850P would be capable of such large print sizes. A PEEK delta 3D printer, the Tractus T850P cuts out a lot of weight-adding extras associated with standard cartesian PEEK 3D printers, weighing just 30kg when competitors routinely weigh over 500kg.

As a delta 3D printer, the T850P can print quickly, even with PEEK, up to 450mm/s. The print head can reach up to 450°C for high temperature Ultem 3D printing, and both the heated chamber and heated bed can reach up to 175°C.

Though it can 3D print PEEK, carbon PEEK, PEEKQ and Ultem, the Tractus T850P functions just as well printing more standard filaments like PC, PP, ASA and others. Tractus say their PEEK 3D printer has been used in the healthcare, manufacturing, education and automotive industries, helped by its fantastic up-to-10-micron resolution. Overall, the Tractus T850P is a great lower cost PEEK 3D printer for fast PEEK additive manufacturing.

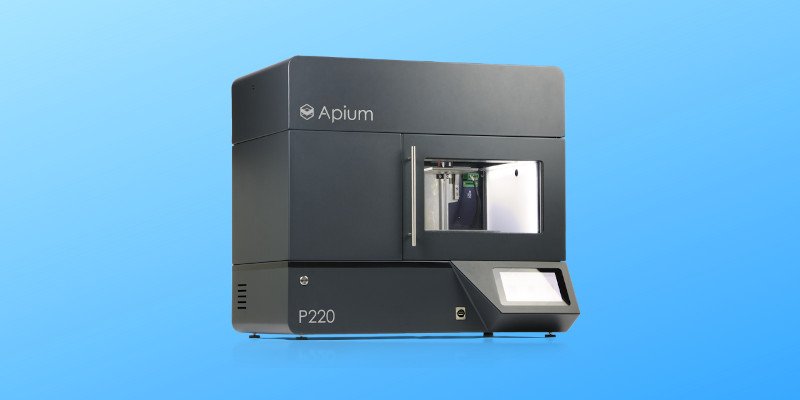

3. Apium P220 — PEEK 3D printer for medical & healthcare

- Price: $30,000 — $50,000

- Build volume: 205 x 155 x 150 mm

Pros

Great for the medical sector.

Features a camera system for easy monitoring.

Can print with metal filled filaments like stainless steel, which can then be sintered.

Cons

Small build volume.

One of the smallest PEEK 3D printers on our list, the Apium P220 can 3D print PEEK, PEI and carbon fiber PEEK materials. You can even 3D print metal filled filaments like stainless steel, which can then be sintered.

Apium highlight how the P220 can 3D print PEEK in high crystallinity, creating fully crystallized parts using their specially-designed Adaptive Heating System. Carbon fiber PEEK filaments can be printed with up to 30% fibers.

Targeted towards the medical sector, the Apium P220 can 3D print medical implants and devices in its sterile and safe printing area using biocompatible PEEK material. It’s made from metals like titanium and steel within the build area, so any medical parts are safe to come into contact with them during the printing process.

Apium’s innovative Adaptive Heating System is their alternative to standard heated chambers. It involves the Ultem 3D printer’s nozzle moving with a heated surface, so as the Apium P220 prints, it also exerts heat on the uppermost layers. As Apium stress, the highest layers are the most important to heat at the time, and so the heated sits close on top of the part while the extruder prints, as their version of thermal post treatment.

Apium’s PEEK 3D printer features a camera system for easy monitoring of your part and the temperature for consistent temperatures. Some might expect less power as it’s a smaller 3D printer, but the extruder can reach temperatures of up to 540C, with up to 160°C on the print bed, and 180°C from adaptive heating. It’s also accurate, offering up to 0.05 mm layer thicknesses for precise and intricate PEEK part prototyping.

4. AON3D AON-M2 — large PEEK 3D printer

- Price: $49,999

- Build volume: 450 x 450 x 640 mm

Pros

Versatile and large.

Can print over a hundred different materials.

The independent dual extruders can both reach temperatures that exceed 500°C.

Cons

Focuses on PEEK and Ultem 3D printing, which will turn some people off it.

A versatile large 3D printer, the AON-M2 is the second printer from Canadian 3D printer manufacturer AON3D. Though it focuses on PEEK and Ultem 3D printing, the AON-M2 can print over a hundred different materials, ranging from tougher, industrial filaments like carbon fiber PEEK, to more standard 3D printer filaments like TPU, Nylon, and ABS.

The independent dual extruder heads can each reach temperatures in excess of 500°C, with a high temperature heated chamber and a build plate that can reach temperatures over 200°C — the AON-M2 will have no problem matching the required temperatures for Ultem or PEEK 3D printing.

One of the main benefits of the AON-M2 however is the huge build volume. At 450 x 450 x 640 mm, huge PEEK prototypes can be created in single pieces, saving time and effort assembling parts from multiple parts. The Z-axis especially is a great benefit, with tall parts able to be 3D printed in one.

The filament storage dryers are another nice touch, controlling for moisture and heat that could affect your filaments, and overall, the AON-M2 is one of the best PEEK 3D printers for general PEEK and other material prototyping and manufacturing.

5. 3DGence Industry F420 — powerful dual extruder PEEK 3D printer

- Price: between €49,000 – €75,000

- Build volume: 380 x 380 x 420 mm

Pros

Able to reach extruder temperatures of up to 500°C.

Speeds of up to 400mm/s and 1 meter per second travel speed.

Can comfortably 3D print PEEK, Ultem, PEKK, and more.

Cons

No major drawbacks.

Polish 3D printer manufacturer 3DGence specialize in large, industrial 3D printers for high quality prototypes in tougher materials. The Industry F420 offers all the tools for effective PEEK and Ultem 3D printing, able to reach extruder temperatures of up to 500°C, heated chamber temperatures of 180°C, and stably maintain these temperatures to avoid imperfections in your part.

3DGence emphasize the speed the F420 offers: with speeds of up to 400mm/s and a travel speed of one meter per second, it’s one of the most scalable and fast 3D printers for PEEK around, able to print accurate prototypes quickly for fast iterations and innovation. Moreover, with the F420 able to print soluble supports for PEEK parts to be dissolved away after, it’s capable of creating some of the best quality PEEK parts around — with no imperfections from support removal.

The Industry F420 can comfortably 3D print PEEK, Ultem, PEKK, and more, and its versatility means it has uses across a variety of sectors. Case studies on 3DGence’s site show how the Industry 420 PEEK 3D printer has benefited users in the medical, automotive, architecture and education sectors.

And if you’re looking for a 3DGence PEEK printer but don’t need quite the same specs or have a smaller budget, you can opt instead for 3DGence’s industry F350 or F340 printers.

6. 3ntr Spectral 30

- Price: $100,000+

- Build volume: 300 x 300 x 300 mm

Pros

Built-in advanced controls to maintain the printing environment.

Can reach up to 500°C, with a heated chamber of up to 250°C.

Built as a versatile manufacturing machine.

Cons

Expensive.

Designed with materials like PEEK, PAEK, Ultem and PPSU in mind, the 3ntr Spectral 30 has built-in advanced controls to maintain the printing environment for perfect PEEK 3D printing. It also features four VENTO drying unit to keep filaments dry for optimal results, and can hold up to 5 kilos of filament each.

The Spectral 30’s extruder can reach up to 500°C, with a heated chamber temperature of up to 250°C, more than enough to 3D print PEEK and Ultem materials. The build volume is large enough for all but the largest prototypes, and for most rapid prototyping should suffice.

Built as a versatile manufacturing machine, the 3ntr Spectral 30 offers a range of mid-print analytics for monitoring your print as it is made, so you can step in if any errors occur and help avoid any expensive ruined prints. Moreover, the post-print data reports offer a deeper insight into the printing process and allow you to optimize based on the data for the best quality parts.

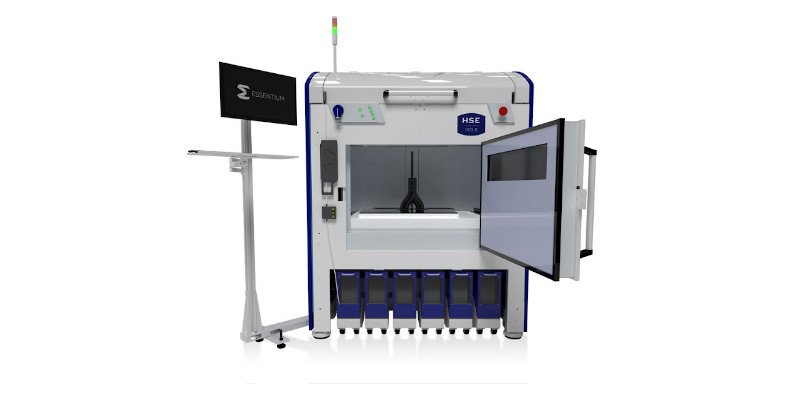

7. Essentium HSE 180-S HT — industrial PEEK 3D printer

- Price: around $150,000

- Build volume: 690 x 500 x 600 mm

Pros

Claims to print 5 to 15 times faster than the competition.

Speeds in excess of 500mm/s.

Used in a variety of different industries.

Cons

Large size will put some people off.

The most expensive printer on our list.

A huge beast of a PEEK 3D printer, the Essentium HSE 180-S HT claims to print between 5 and 15 times faster than its competition — as well as able to print strong, and cheaply, all in one machine.

This speed, in excess of 500mm/s, makes for scalable PEEK and Ultem part production and the ability to print large parts at record speeds. For larger prototypes especially this slashes iterating times, allowing for quicker upgrades and performance improvements.

The HSE 180-S HT is positioned as a PEEK 3D printer for the aerospace and defense, oil and gas, high pressure tool making, as well as other sectors and applications including jigs and fixtures, and other functional parts.

The huge build volume means almost any prototype can be made in one part, and the sapphire-tipped nozzle won’t be worn down by the abrasive PEEK and carbon fiber filaments as even hardened steel nozzles eventually are. The printer also features dry air canisters for filaments using Essentium’s Filament Care System that retains your filament’s optimal properties, keeping them from the moisture in the air.

The differences between PEEK, Ultem, PEI, PAEK, and PPSU

First invented in the early 1980s, PAEK refers to all the materials within the Poly Ether Ketones family — and includes PEEK, PEKK, and many others like PEK, PEEKK, and PEKEKK. Of these, PEEK is the only one to see wide use.

Ultem is the brand name for PEI products used by manufacturer SABIC, so if you see PEI 3D printers mentioned anywhere, it means Ultem. PEI is commonly used as a 3D printer heated bed material, but also has uses as a high performance polymer.

Ultem is similar to PEEK, just PEEK is semi-crystalline while Ultem is amorphous, which affects their heat resistances and glass transition temperatures. PEEK’s 143°C glass transition temperature is considered higher than Ultem, and it has slightly better tensile strength, but is also more expensive than Ultem. PEEK generally costs around $500 per kilo, whereas Ultem costs around $250 — though this can vary.

PPSU is similar to PEI in that it is a similar material that is also amorphous, but offers better impact and chemical resistance than Ultem.

All PEEK filaments will deteriorate if left in the open air, and it is integral to keep them away from open air and light when not printing.

If you’re looking for a high temperature 3D printer for PEEK or Ultem, or other similar material, we may be able to help.

*One of our trusted partners will be in touch following a quote request.

What to look for in a PEEK 3D printer or Ultem 3D printer?

Peek and Ultem are far more difficult to 3D print than standard filaments like PLA or ABS. They are fantastically strong, and as a result need far higher extruder, heated bed and heated chamber temperatures to print effectively. As a result, you’ll need a high temperature 3D printer.

Extruder temperatures of 400°C are expected for a PEEK 3D printer, as well as a heated chamber of above 100°C, and a heated plate of easily 150°C. Since most professional 3D printers can’t handle these temperature levels, companies have developed specialized high temp 3D printers for PEEK, Ultem and Carbon fiber PEEK 3D printing.

Both PEEK and PEI / Ultem do not react well to undulating temperatures — a heated chamber that can keep temperatures very stable is crucial for high quality PEEK parts. Therefore, the PEEK printers we list all have high quality heated chambers and heat maintaining systems to prevent ruined PEEK or Ultem parts.

PEEK powders are also available for SLS 3D printers, and sold by German manufacturer EOS as their PEEK HP3 powder.

PEEK and Ultem 3D Printing Applications

Peek is used across the aerospace industry making parts that need to withstand powerful forces, as well as to make parts that come into contact with fuel, as its inflammability makes it an effective material for coming into contact with gas and oil. It’s used to replace the same metal parts when using PEEK saves weight — a huge money saver in aerospace.

In medical, PEEK and Ultem are used as they are sterilizable and biocompatible, making them ideal as 3D printable implants and for medical devices.

PEEK 3D printers are also used in education, such as in universities for research and development, and in the defense and architecture industries.

However, with PEEK being so expensive, it has not yet broken through into mainstream everyday use, and remains a niche high-performance material for industrial uses.