ABS was the first widely used 3D printer filament, and cemented itself as the go-to for 3D printing until PLA became used following the RepRap movement and DIY 3D printers. Now, PETG filament is increasingly used due to its fantastic layer adhesion, ease of printing, and chemical resistance. Does PETG pose a threat to ABS’ dominance?

To find out, we compared PETG vs ABS on a wide variety of key comparison points, including price, how easy they are to 3D print, environmental friendliness, how easy they are to store, and which of PETG or ABS makes for more attractive prints.

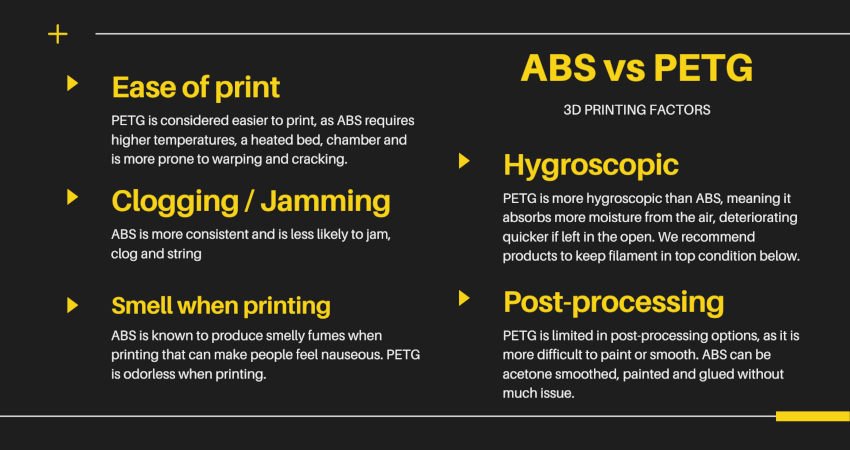

ABS vs PETG: 3D printing factors

Temperature, heated bed and chamber

PETG is considered easier to print than ABS. Firstly, ABS is a tough material that requires not only a high extruder temperature to print, but also requires a heated bed at over 100C, as well as a heated chamber. Without a heated bed and chamber, ABS parts tend to warp badly and crack between layers, curling up at the corners of the part – especially on long and thin prints.

Not all 3D printers can heat up to the temperatures ABS requires. Many printers that have PEEK hot ends or PTFE-lined 3D printer parts struggle with the temperatures associated with ABS 3D printing, with makers choosing instead to upgrade to all-metal parts such as E3D hot ends. This is not required for printing PETG.

Moreover, many 3D printer kits and RepRap 3D printers do not have print chambers as they are open builds, and will struggle badly with ABS printing.

PETG on the other hand has no such problems, and can even be printed without a heated bed, though we still recommend using one.

ABS vs PETG: Bed adhesion

PETG also has the best adhesion of any 3D printer filament, sticking extremely well to build surfaces – sometimes too well, taking gauges out of your print bed or PEI sheets! – whereas ABS sticks worse to both itself (causing cracks between layers) and to build surfaces.

ABS vs PETG: reliability, jamming and clogging

PETG is considered more prone to clogging, stringing and jamming during printing. This can be a hassle, especially if it causes failed prints that waste time and filament. To minimize these occurrences, ensure your print settings and extruder temperature are optimized based on the type of filament you are using.

ABS vs PETG: which smells least during printing

Moreover, whereas PETG prints without any strong smells, ABS is known for the smelly fumes it produces. This makes ABS less suitable for printing in rooms where you might do other work while your 3D printer works, as the fumes can be uncomfortable and nauseating.

Hygroscopic

ABS is one of the least hygroscopic filaments, and one of the few materials you can leave out for longer periods of time without the filament’s quality dramatically worsening. It is still absolutely worth investing in a filament dryer and filament containers to ensure your ABS filament remains in fantastic condition, but it is less of a necessity as opposed to filaments like Nylon.

PETG is more hygroscopic than ABS, and should always be kept in a container and away from exposed air.

We recommend the following containers for keeping filament dry and in top condition:

ABS vs PETG: Post-processing

Overall, ABS is the better filament for post-processing after you’re finished 3D printing.

ABS is easier to paint, as well as being easier to glue parts together. PETG’s stickiness and slipperiness makes layers of paint more difficult to hold.

Additionally, ABS can be acetone smoothed for a glossy surface appearance, whereas PETG’s chemical resistance means that isn’t an option for PETG.

ABS vs PETG: Price, Which is Cheaper?

ABS is cheaper to buy than PETG overall, starting at around $20 per kilo, whereas PETG starts at around $25 for basic PETG. Higher quality blends of PETG can go up to around $55 however.

We recommend the following filament ranges:

- ABS filament recommendations on Matterhackers

- PETG filament recommendations on Matterhackers

- High quality PRO Series PETG available here

- 3DJake UK & Europe PETG selection

- 3DJake UK & Europe ABS selection

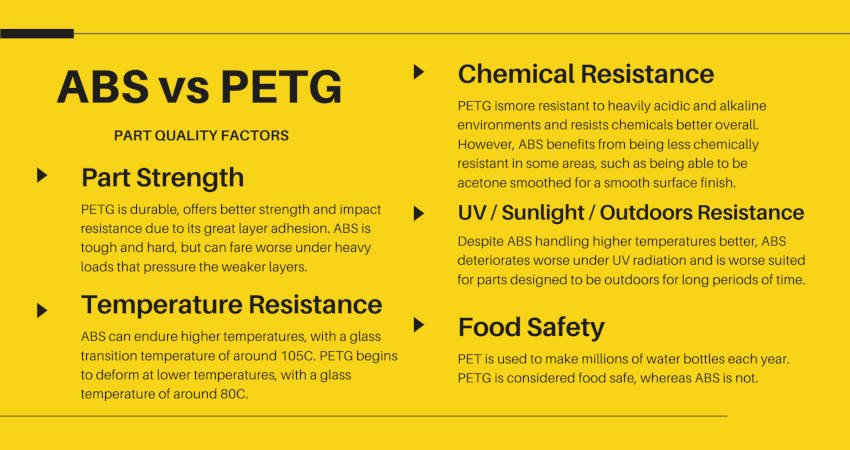

ABS vs PETG: Part Quality Factors

ABS vs PETG: Which is stronger? And which has better impact resistance

Whereas PETG is more durable, ABS is more rigid and hard.

PETG is viewed as stronger due to its better layer adhesion creating strong parts that can take powerful impacts. PETG’s rigidity grants it better impact resistance, allowing it to dissipate these forces more easily on impact. ABS suffers due to weaker layer adhesion, and can falter when facing heavy loads, especially when they put pressure on these weakly held layers.

That being said, both ABS and PETG are known for being very tough filaments, and neither can be broken or deformed easily.

ABS however is more scratch-resistant, whereas PETG is known for being easy to mark and scratch.

ABS vs PETG: Heat resistance

One of the best filaments for high temperature applications, ABS is used in applications such as for handles on tools that need to be used in hot environments where materials like PLA would start to deform.

ABS has a glass transition temperature of around 105C, significantly higher than the glass transition temperature of PETG, which starts to become rubbery at around 80C. For high temperature parts, ABS is the better option.

ABS vs PETG: Chemical resistance

PETG has better chemical resistance overall, but this is not always a positive. For example, ABS’ vulnerability to acetone allows it to be smoothed, making ABS parts shiny, glossy and radiant.

For industrial uses however, PETG shines, and can handle both acidic and alkaline environments and chemicals far better.

ABS vs PETG: Sunlight / UV resistance and outdoors

Though ABS can handle higher temperatures than PETG, ABS is also weaker to UV radiation from the sun, causing it to degrade more heavily than PETG. PETG is therefore the better filament for outside use parts and models.

ABS vs PETG: Food safety

ABS is not considered food safe. PETG, on the other hand, often is. Millions of PET plastic bottles are made every year, and PETG is PET with added glycol. Therefore, PETG is better for food and drink-related applications than ABS.

ABS vs PETG: Environmental Friendliness

Neither ABS or PETG are biodegradable like PLA is, with PLA the runaway winner for best filament for the environment.

However, both plastics can be easily recycled. Therefore, though neither filament is made from renewables and biodegradable, if you take care to recycle them then they are not too environmentally unfriendly.

Aesthetic factors

If you are looking for a filament for purely aesthetic purposes, AKA which will look best for your models, the answer is that it is mostly subjective and based on your preferences.

PETG’s biggest strength appearance-wise is that it is transparent and glossy – almost glittery – which can look great in intricate pieces such as jewelry, as well as vases, 3D printed miniatures, and more. However, you are limited to this finish, as it is a struggle to paint or polish PETG 3D printed parts.

As for ABS, it cannot be transparent, but is available in an extremely wide range of colors. It can also be acetone smoothed for a shiny effect that looks great, and painted any color using acrylic paints, making it a better option for characters that need to be painted different colors for hair, clothing and facial features.

ABS vs PETG: Applications

Outside of 3D printing, ABS is most well-known for making up LEGO bricks. It is also used sporadically in bike helmets, electronics casings, and other tough parts that need to withstand heat, like handles for tools.

PETG is commonly used in bottles and food and drink containers, as well as point-of-sale signs and tabletop displays. It also sees some use in prosthetics, and in orthotics.

Conclusion

Overall, we recommend ABS for any printing related to high temperature uses, or for those who want to paint, polish via acetone, or glue several parts together. Additionally, if you want to leave your filament out in the open then ABS works well, and will clog and jam less.

However, we recommend PETG if you prefer to print without all the added accessories like a heated chamber and heated bed without warping – especially if you have a 3D printer kit – and prefer the transparent look PETG offers. For any parts that need good impact resistance, less rigidity, and need to face up to chemicals or sunlight, go with PETG.

More articles you may be interested in:

- The best ABS 3D printers

- ABS vs ASA

- Complete guide to ABS filament

- Complete guide to PETG filament

- Complete guide to PLA filament

- PLA, ABS, and PETG shrinkage: Everything you need to know